Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Nov 30, 2018 8:09:48 GMT -8

The ceramic fiber was perfect white, like it had never seen a season of use, but everything outside the riser was covered in soot. Clean surfaces do not indicate a clean burn, nor even a very hot one.

Wood tar pitch has boiling points above 350°C/662°F and an auto-ignition temperature above 500°C/932°F. Decomposition may happen close to the boiling point.

Clean surfaces need to exceed at least the highest boiling point for a sufficient time.

|

|

|

|

Post by permaculturebob on Dec 5, 2018 6:06:38 GMT -8

thanks for those reference temperatures, I'm guessing the thought you are transmitting is the CF riser temps could have stayed in that sweet spot between 600 and 900, immediately cooling in the bell to condense the soot. That makes lots of sense, fortunately I took the thing apart after a season with that new riser and didn't continue with the poorly executed batch box design.

even so, I was grateful for the reduced tending time loading the heavier and extra fuel allowed.

I thought the ignition of those secondary gases was closer to 1100F, that explains why I was getting so much secondary combustion in my new dsr with glass cooking top surfaces near 890. Is there a way to infer the internal temps of the top shoebox from the external readings, some sort of expected gradient? |

|

|

|

Post by ronyon on Dec 6, 2018 6:00:31 GMT -8

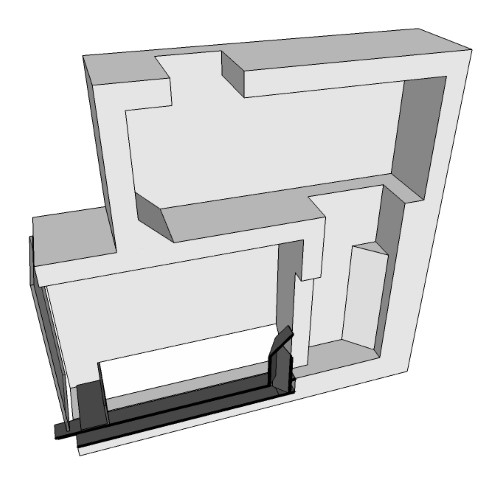

Forgot to show how it looks like from the top. It's evident that the riser is narrower than either the firebox or the topbox. In my view both boxes could be built like... a box complete with port while three sides of the riser stub could be formed using split firebrick. Very much like a liner inside the box, Yasin did something similar but at this time I can't find the relevant picture.  Peter can you tell us about the triangular prisms inserted in the back corner of the square riser? Are they port high? The P-channel, is it half as high as the port? The top box, how much does it add to overall height? |

|

|

|

Post by Jura on Dec 7, 2018 0:40:17 GMT -8

I get 404 Not Found after clicking on the link. Edit: I fixed it just now. Peter |

|

|

|

Post by peterberg on Dec 7, 2018 3:07:22 GMT -8

Peter can you tell us about the triangular prisms inserted in the back corner of the square riser? Are they port high? Yes, those are port high. Sized in such a way that it forms half an octagon at the back of the riser. The P-channel, is it half as high as the port? Yes, the floor p-channel is half as high as the port in this drawing. The top box, how much does it add to overall height? Hmmm... As much as the internal width of the firebox plus the thickness of the topbox' lid. Assuming the system size is 6" and (casted) walls of 1.25" thickness the height of the reference model would be 15.52", including top and bottom. The top box would add 9.93" in this case, totalling up to 25.45". The same 6" system but equipped with a 10B riser would be 44.65" high so the DSR2 offers a reduction of 19.2" or 43% in height. In case full firebricks on edge are used one need to calculate that in of course. In line with DSR1 I'd expect the top box could be equipped with a neoceram top to enable cooking. Hope this is clear. |

|

|

|

Post by ronyon on Dec 11, 2018 10:04:23 GMT -8

Very clear, thank you Peter.

|

|

|

|

Post by BenAlexanderT on Dec 13, 2018 23:15:48 GMT -8

What height is the threshold in this 12cm system?

|

|

|

|

Post by peterberg on Dec 14, 2018 1:25:54 GMT -8

What height is the threshold in this 12cm system? In this particular setup 40 mm, 50 mm away from the low and thin slit between glass and floor. In case the primary and secondary air are combined in a single inlet like the standard core with floor channel, this threshold should be 60 or 65 mm. The crux of the thing is the height difference between the air inlet and the top of the threshold. |

|

|

|

Post by doughboydan32 on Dec 14, 2018 7:53:04 GMT -8

Nice work Peter. All that ceramic fibre board must have cost you a lot. is that what it is . thought it look like firebrick ? |

|

|

|

Post by Vortex on Dec 14, 2018 9:36:28 GMT -8

Nice work Peter. All that ceramic fibre board must have cost you a lot. is that what it is . thought it look like firebrick ? The firebox and first tapered rise was just CFB donkey32.proboards.com/post/30372/thread Since then Peter seems to have been mainly using IFB |

|

|

|

Post by stefanvh on Jan 28, 2019 9:05:25 GMT -8

Is there a design of the DSR2 'ready for production'? I am looking to build a rocket mass heater and this new design looks really promising. And as much as I would like to do some experiments, a working design for a stable burn is preferred during cold days  . Or would you advise to stick to a batch rocket design for now? |

|

|

|

Post by peterberg on Jan 28, 2019 13:04:07 GMT -8

Hi Stefan, welcome to the boards. Is there a design of the DSR2 'ready for production'? I am looking to build a rocket mass heater and this new design looks really promising. Or would you advise to stick to a batch rocket design for now? The principals of the design are fixed, I fully expect it to be as scalable as the straight batch box or sidewinder. Just take the size of batchrocket you need for your application. Replace the riser above the top of the firebox with a top box as wide and high inside as the width of the firebox. Opening on top the same csa as the riser stub and bob's your uncle. The top box is meant as a replacement for that high riser, in most circumstances it's also usable as an oven. |

|

|

|

Post by wiscojames on Jan 28, 2019 13:57:40 GMT -8

Bob's your uncle? Is that a Dutch saying, Peter?

|

|

graham

Junior Member

Posts: 74

|

Post by graham on Jan 28, 2019 18:22:14 GMT -8

How about the riser entering the top box at the front instead? So, it's like a step up some boxes. It would double the depth of the stove though.

|

|

|

|

Post by peterberg on Jan 28, 2019 23:09:27 GMT -8

Bob's your uncle? Is that a Dutch saying, Peter? As far as I know it's English, London, maybe even cockney? |

|