|

|

Post by peterberg on Nov 14, 2018 3:15:54 GMT -8

With the firebox DSR2 are there overloads during combustion of a single load of wood (when the flame goes above the roof of the upper box)? Are there any overloads if you burn two loads of firewood one by one without interruption in DSR2? How does DSR2 work if you put firewood during the burning of the first wood load? Ooww! Questions! About 30 minutes ago I ran the 10th test with the latest configuration. Results across all ten are such that I would dare to say this is a real alternative, no real overload to date. Despite me using sometimes small softwood scraps, ash wood containing => 25% moisture plus mixed circumstances, like no wind at all and gusts of wind during several test runs. Your second and third question can't be answered yet, both are on my list. Note: the thingy being tested now appears as stable as the straightforward riser version so I would be surprised to find unique surprises down that path. |

|

|

|

Post by sksshel on Nov 14, 2018 4:19:30 GMT -8

I have been thinking about a way for a DSR to be implemented into an existing masonry fireplace with a hearth. Based upon the limited research I've done, the dimensions of the DSR could fit nicely. The Bell could be built upon the existing hearth. Hearths are typically supported by concrete foundations. The existing chimney would need to be extended downward to pull cooled vapors from the bottom of the bell. There are many items to work out, but it seems to me to be something to explore.

With all of that lead-in, is there a variation of the DSR2 that would fit this scenario?

|

|

|

|

Post by peterberg on Nov 14, 2018 5:55:59 GMT -8

There aren't any other variations to date of course, but I could think up some. One would be a sidewinder DSR2, the topbox at right angles with the firebox.

|

|

hanee

New Member

Posts: 23

|

Post by hanee on Nov 16, 2018 6:53:13 GMT -8

This is fantastic news. I have been trying to chose between somewhat similar "riserless" or "double box" type designs (Vortex, Walker, Yasin's 'batchblock'). It would appear that the DSR2 design will be simpler to build and/or more rigorously defined and tested. It is also a great sign that these results are with a 120mm system. I am going to begin working up a design for a 100mm system for our tiny house (192sqft, well insulated), which I'm guessing is going to be more towards the lower limit.

Am I right that this would be a drop-in replacement for the combustion core, in terms of all other design parameters remaining in the same proportions/relationships (chimney size, bell ISA, etc), to a standard BBR?

|

|

|

|

Post by peterberg on Nov 16, 2018 7:24:06 GMT -8

Am I right that this would be a drop-in replacement for the combustion core, in terms of all other design parameters remaining in the same proportions/relationships (chimney size, bell ISA, etc), to a standard BBR? That's what I'm aiming at, yes. I think we are quite close now, more results during coming weekend hopefully. When all is going according to plan, the design parameters could be on the batchrocket site around Christmas/New Year. |

|

|

|

Post by peterberg on Nov 17, 2018 3:26:16 GMT -8

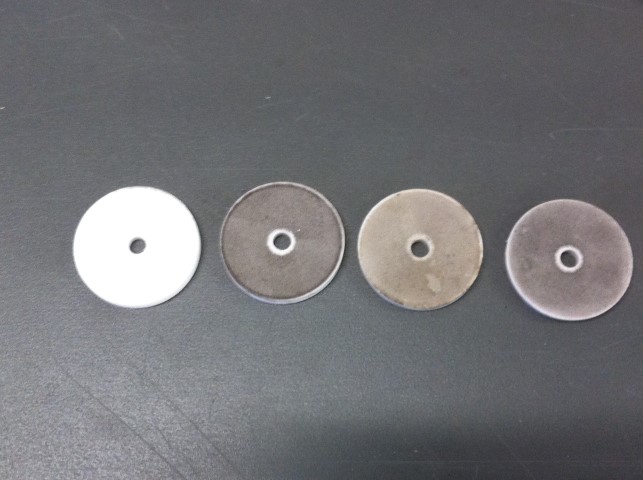

Most things on my list are done, it's evaluation time. What I could do is showing all the best graphics and the most impressive pictures but I won't. I'd think it's better to show the extremes and whether there're good or not and why. So let's concentrate on the latest 3 of all the test runs to date because there's something to tell about it. Run number 8 on the wider top box with exhaust opening towards the front. High moist (=>20%) ash fuel, pine on top and gusts of wind, not the best circumstances to compare results.  Averages: 14.4% O², 86.7% eff., 630 ppm CO, 125.2 ºC. Not bad at all, considering the sharp peak of CO halfway in the burn. Number 9 of the same row, Moist ash again plus some pine on top, coming on slow, gusts of wind.  Averages: 14.8% O², 87.1% eff., 1091 ppm CO, 121.4 ºC. This is one of the runs that's outside defined specs, although not by a large margin. There's a peak much earlier in the burn, strangely coupled with a rise in O² this time. Number 10 of this series, done with 2x3 lumber scraps and some smaller kindling on top. Wind was virtually absent, in sharp contrast with numbers 8 and 9.  Averages: 14.3% O², 91.6% eff., 653 ppm CO, 83.2 ºC Within specs but not an all time stellar example. Rise of CO in the second half puzzled me, can't think of a reason why it was like that. The interesting thing about these test runs is the difference in colour of the Testo's white probe filters.  From left to right: an unused filter and the test runs 8, 9 and 10. The middle one, number 9, is the lightest colour of all three while this was the one outside specs because of a too high CO level! Conclusion could be that quality of the burn measured by CO level has less to do with black carbon pollution than one might think. Keep in mind that all three are school examples of very light colouring of these filters. |

|

serg247

Junior Member

The mountain can not be conquered, it can allow it to ascend...

The mountain can not be conquered, it can allow it to ascend...

Posts: 111

|

Post by serg247 on Nov 17, 2018 5:20:37 GMT -8

Hi, Peter. Was a thrust stabilizer used? You can learn more about measurements for Russian skeptics.  |

|

|

|

Post by peterberg on Nov 17, 2018 6:14:13 GMT -8

Hi, Peter. Was a thrust stabilizer used? You can learn more about measurements for Russian skeptics.  No thrust stabilizer, I've never used one during any of my tests. There's even a reason for that: most if not all wood heaters in domestic use do not have one. |

|

serg247

Junior Member

The mountain can not be conquered, it can allow it to ascend...

The mountain can not be conquered, it can allow it to ascend...

Posts: 111

|

Post by serg247 on Nov 17, 2018 7:09:57 GMT -8

In one of the posts it was mentioned about the stabilizer 12 Pa according to the European standard. What caused the reaction in a person familiar with the well-known scandal with gas analysis in diesel engines, where the readings were diluted with excess air.

|

|

|

|

Post by peterberg on Nov 17, 2018 7:29:34 GMT -8

To round up evaluation I've also done the tests ssr requested. Only one of both and there's something interesting to tell about those. First one to establish whether or not this test bed could withstand adding fuel every now and then to keep the thing going.  Averages: 13.8% O², 85.8% eff., 618 ppm CO, 137.3 ºC. At first I loaded the firebox as normal, lit it on top and waited until nearly all of the long yellow flames were gone. Then I added two moderate (for this small system) sized pieces and let it go again. Oxygen went sharply down and efficiency up accompanied by some wobbling in the CO department. At the time the fire was back at the stage of a few flames I added one chunky piece with a lot of surface area plus a shorter and smaller piece. No surprises, sharp up and down were there again plus a more pronounced wobble in the CO level. Quality of the burn corrected itself quite nice, steeper than at first. The third time I added three moderate pieces so I could see the effect of more fuel in an absolutely scorching hot combustion core. I do use welding cloves for this type of actions, that's no luxury. Same pattern again, ups and downs but the CO wobble was now at the height of the first one and as steep as the second. It looks like I could repeat this pattern quite easily, so this system is able to deal with adding fuel now and then. I went outside a couple of times to see what the exhaust gases looked like. Wind was just a breeze and blue sky at the background, see picture.  Temperature of the uppermost barrel close to the top went up to 270 ºC (500 ºF), I had to open all windows and it was still too hot inside my workshop.  Next test was done in order to answer the question whether this thingy could withstand a complete refill on top of a big glowing coal bed. At first I loaded the normal amount in the (then cold) firebox.  I let it go up to the stage where there wasn't any flame to be seen and loaded it up with this 6 moderately sized pieces.  It catched fire almost instantly, yielding a very aggressive roar. Upto 5 minutes into the refill it went well, CO was ascending, etc. Then a fuel overload occured, sending the CO line into the sky. After a couple of minutes it came back down to go up again, repeating that until the third time around it stayed down and coasted to the normal end-of-test. I let it go a bit longer so I could see what happened but CO wouldn't go down until oxygen was up at 19%.  Averages: 13.7% O², 83.4% eff., 2169 ppm CO, 140.1 ºC. Of course this one was way out of specs, so this isn't an action to be repeated. View of the firebox while it was well underway to the first steep decend:  Conclusion so far: one could add a couple of pieces at the time. But for to load a firebox full on top of a large coal bed this need to deminish quite a bit before doing that. By the way, adding that lot to the firebox wasn't a pleasure, the radiation would light a piece of paper at a distance of 5", or so it seemed. This two test runs I used a fresh filter for the probe, like before. So now I have two used filters to show, accompanied by a new one for reference.  From left to right the reference filter, test with adding three times and the complete refill. Mark the darkest one actually isn't pitch black but just dark grey instead. The adding-a-few-pieces-at-the-time test isn't even grey but more like dingy, for want of a better fitting word. |

|

|

|

Post by peterberg on Nov 17, 2018 7:37:50 GMT -8

In one of the posts it was mentioned about the stabilizer 12 Pa according to the European standard. What caused the reaction in a person familiar with the well-known scandal with gas analysis in diesel engines, where the readings were diluted with excess air. Yes, I've seen that post, Max was the poster if I recall correctly. It's a good thing I don't have to make money with these heaters, otherwise nobody would see these test results. Publishing only the absolutely nicest ones would be too tempting, don't you think? |

|

|

|

Post by Dan (Upstate NY, USA) on Nov 17, 2018 7:40:15 GMT -8

Interesting

|

|

serg247

Junior Member

The mountain can not be conquered, it can allow it to ascend...

The mountain can not be conquered, it can allow it to ascend...

Posts: 111

|

Post by serg247 on Nov 17, 2018 8:13:44 GMT -8

Thank you Peter. Personally, I have no doubt ...

|

|

ssr

New Member

Posts: 7

|

Post by ssr on Nov 17, 2018 9:43:35 GMT -8

Thank you, peterberg. This is great news. This method of adding wood to a fire box is ideal for long-term cooking on a wood-burning stove. In addition, the design of the DSR2 has an advantage over a conventional riser, its height is small, this will make the cooking stove comfortable in height. In the DSR2 design, the top box can be used as a small black oven. This design is ideal and versatile for the cooking. As a result, with the design of the DSR2 we get the opportunity to make a comfortable cooking stove with an oven for cooking and an excellent stove for heating and simple project that works great !!!!

|

|

|

|

Post by ronyon on Nov 18, 2018 8:44:12 GMT -8

Hi, Peter. Was a thrust stabilizer used? You can learn more about measurements for Russian skeptics.  No thrust stabilizer, I've never used one during any of my tests. There's even a reason for that: most if not all wood heaters in domestic use do have one. What is a thrust stabilizer? Google gives me nothing related to wood heat. Is it a draft inducing fan perhaps? On another note,has there been a configuration with the exhaust built into the front face of the topbox? I suspect that final 90 degree turn in the flow of gas is a desirable feature. I'm not sure if there would be any advantage in exhausting out the front anyway. In fact it would concentrate heat on the sidewalk of the barrel,a potential problem. In a flat sided "barrel" this could be a great place for a window, allowing one to look directly into the heart of the beast. Putting the exhaust on the side of the topbox could useful, adding a twist into the path of the gasses, and it would be oriented along the wall of the barrel, not pointed directly against it. This topbox,seems like something that could be stacked. Could a second topbox further improve performance? If a topbox can approach the performance of a tall, straight riser in much less vertical space, could a stack of topboxes exceed the that performance in the same vertical space? Thank you for sharing your work and fielding our questions. |

|