|

|

Post by satamax on Nov 18, 2018 8:50:14 GMT -8

|

|

serg247

Junior Member

The mountain can not be conquered, it can allow it to ascend...

The mountain can not be conquered, it can allow it to ascend...

Posts: 111  Member is Online

Member is Online

|

Post by serg247 on Nov 18, 2018 9:37:51 GMT -8

|

|

|

|

Post by ronyon on Nov 18, 2018 16:23:41 GMT -8

Thanks guys!

|

|

|

|

Post by peterberg on Nov 26, 2018 12:28:22 GMT -8

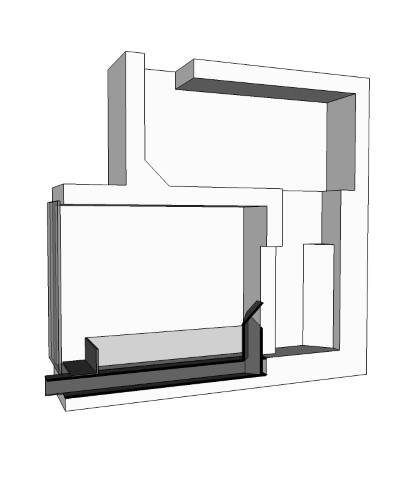

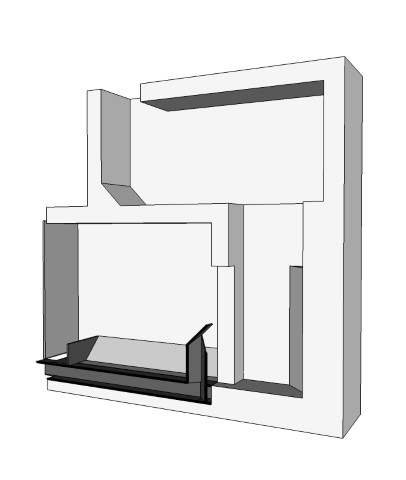

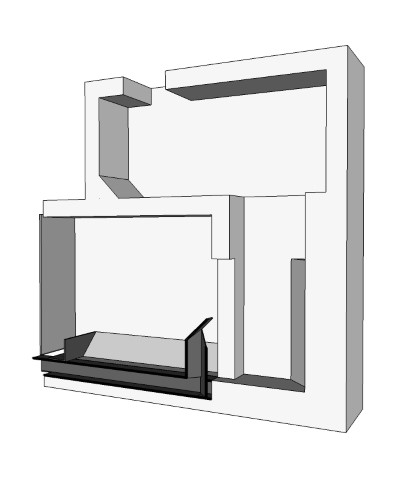

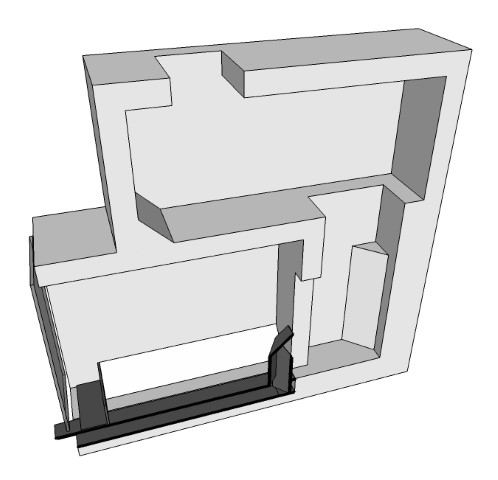

Last weekend I've made a drawing of the principals of the DSR2. It's a cut-out model so one is able to see what is where. The fact that the top box is shorter as compared to the firebox is a consequence of the chosen heat extractor for this particular test series, two barrels. No more space inside so I tried it this way. I hope and expect a deeper top box would work just as well.  Air intakes are a small slit under the glass panel and a floor channel duct in a 50/50 proportion. To start, I opened the glass panel a lot more until the fire was established (most of the time within 7 minutes) and then closed it to the minimum size. The floor channel's throughput wasn't restricted in any way. Another picture, seen from the other side. There's a threshold that is about 2" away from the air inlet. I tried several different approaches, this happened to be the most effective and yielding the best results throughout the test series. Again, this isn't a heater core as such, just the principals what I've done.  Since two differently placed exhaust openings are tested, here's the other one. All the rest being equal.  This last setup shows the possibilities to use the top box as a black oven. Extending it to the front ending in a door while keeping the exhaust opening at the same position would do it. Sometime this winter I need to cut into the barrels again in order to be able to test this setup. To find out whether it's a true and usable feature. Complete with an object in there that would represent a baking tin or a römertopf. |

|

|

|

Post by peterberg on Nov 26, 2018 12:55:01 GMT -8

Forgot to show how it looks like from the top. It's evident that the riser is narrower than either the firebox or the topbox. In my view both boxes could be built like... a box complete with port while three sides of the riser stub could be formed using split firebrick. Very much like a liner inside the box, Yasin did something similar but at this time I can't find the relevant picture.  |

|

nico

New Member

Posts: 2

|

Post by nico on Nov 26, 2018 13:10:03 GMT -8

Hi Peter,

What do you expect if the exaust is moved to one of the front part side and connected directly to a bench without using a top barrel? Chimney connected to the bench. Can then the top be used for coocking plate with a glass top? Will this design be suitable? I am thinking about an outside cooking stove with a warm bench. I find of little use to have a vertical barrel outside. Perhaps is on a similar line with the Allerton Abbey build.

|

|

graham

Junior Member

Posts: 74

|

Post by graham on Nov 26, 2018 13:17:26 GMT -8

This looks similar to the oven I've been using for the last month except my black oven is above the secondary combustion chamber, and the riser opens into both the dead ended oven and the secondary combustion chamber. I did it that way to try and maximally heat the stone of the floor of the oven for pizza. Flue exits from side of the secondary burn chamber. And baffles ensure roof is heated evenly.

|

|

|

|

Post by peterberg on Nov 27, 2018 6:10:34 GMT -8

What do you expect if the exhaust is moved to one of the front part side and connected directly to a bench without using a top barrel? Chimney connected to the bench. Can then the top be used for cooking plate with a glass top? Will this design be suitable? I am thinking about an outside cooking stove with a warm bench. I find of little use to have a vertical barrel outside. Perhaps is on a similar line with the Allerton Abbey build. #1 I honestly don't know, this need to be tried by someone who's willing to spend quite some money and lots of time. That person might be me but I have other priorities to attend. #2 Analogue to the original DSR, likelyhood of cooking on top is quite good. #3 Be suitable to what? #4 The Allerton Abbey build happened to be an experiment, nothing more. I still don't know whether or not it worked satisfactory or has been used for cooking and heating since over a year ago. |

|

|

|

Post by peterberg on Nov 27, 2018 6:30:55 GMT -8

This looks similar to the oven I've been using for the last month except my black oven is above the secondary combustion chamber, and the riser opens into both the dead ended oven and the secondary combustion chamber. I did it that way to try and maximally heat the stone of the floor of the oven for pizza. Flue exits from side of the secondary burn chamber. And baffles ensure roof is heated evenly. I never said what I did was unique. On the contrary, I'll do my best to give credit where it's due. I understand your build is similar in the sense of having a (short) riser behind the firebox. As built and tested thoroughly during Januari 2018 by Yasin Gach in his batchblock construction. My build is along those lines but utilising a smaller topbox in an attempt to create a compact core. Your build is substantially different in the sense of the riser ending in the secondary box as well as the oven on top of said box. So actually it should be called a Triple Shoebox Rocket or TSR. I doubt this construction would be clean burning, if at all. I fully expect the inside of the oven, secondary chamber and riser to be black sooty at least. |

|

graham

Junior Member

Posts: 74

|

Post by graham on Nov 27, 2018 6:54:28 GMT -8

Yes, it is like that at the start though the draft seems to carry most of the soot away. So, I think I should change it to follow your skp and put the oven opening at the other end. That should give me a cleaner oven?

But the brick opposite the Venturi is very clean. In fact I swap bricks out to use the Venturi to burn off soot from my bricks. And I think when I last pulled this apart the secondary burn chamber looked pretty clean too.

|

|

graham

Junior Member

Posts: 74

|

Post by graham on Nov 27, 2018 11:15:34 GMT -8

BTW, the reason I added a third chamber for the oven is that in one of my videos I observed flames traversing the whole secondary burn chamber and reaching the chimney (at 3:05 of this video youtu.be/Ejg4pAVBKxs ). This was when I had a cast iron cooking plate over the second chamber. So, I thought I couldn't use the second chamber as an oven as there was a potential for too much flame there. |

|

graham

Junior Member

Posts: 74

|

Post by graham on Nov 27, 2018 12:07:44 GMT -8

Peter, if you were to move the Venturi to the side creating a single vortex and cause the gases to move more quickly to the secondary burn chamber. Would this then lead to a greater percentage of combustion and heat release in the secondary chamber vs the riser? Or would it just lead to a dirtier burn?

It looks like the top of the riser forms a second Venturi to the secondary combustion chamber so this will force the gases to slow down as it exits the riser. Is there a second rams horns vortex occurring at the top of the riser?

|

|

|

|

Post by peterberg on Nov 27, 2018 12:19:29 GMT -8

Just replacing the port like that would result in a dirtier burn, in my book. Suppose it could be done with a single vortex, that would mean doing all the development work over again. The height and width of the port, what proportion to the firebox and riser, length of riser or size of top box, shape and placement of the secondary air provision, and so on. Do you see the ramifications before you?

|

|

|

|

Post by permaculturebob on Nov 30, 2018 6:43:14 GMT -8

The idea that soot is not necessarily a direct correlation with CO is quite interesting. It leads to all sorts of other speculations about other incomplete combustion products. Which ones are most dangerous, in what quantities? My own preference would be soot free, but maybe that's not the best measure of a "clean" burn. I recently disassembled my rocket stove that had a season of use with a batch box, and a ceramic fiber liner to the riser to reduce the diameter to 6inches. Inspection showed the actual diameter had shrunk to more like 5 inches. The ceramic fiber was perfect white, like it had never seen a season of use, but everything outside the riser was covered in soot. I have some ideas about what might have happened, maybe the soot was related to too small a secondary air supply- too large a batch box for the actual riser diameter. Maybe the riser just had gases moving too fast in a venturi for anything to deposit

Maybe something else?

|

|

|

|

Post by peterberg on Nov 30, 2018 7:22:08 GMT -8

There is another unavoidable reason for the soot. At every startup the heater need to get up to working temperature. So the first 5 to 10 minutes of the burn it is generating soot. Not much since the initial fire is small, but nevertheless. Your undersized secondary air provision might be also a factor in the end result. The inside of a mass heater doesn't get hot enough to burn the soot off again.

Building a mass heater out of bricks or whatever means there will be a lot of water in there. During the running in period all the water need to vaporise so the heater stays fairly cool initially, collecting relatively more soot during the drying period.

|

|