|

|

Post by hof on Nov 22, 2019 3:55:49 GMT -8

|

|

|

|

Post by hof on Nov 22, 2019 4:31:11 GMT -8

Added photos

|

|

|

|

Post by josephcrawley on Nov 22, 2019 4:55:23 GMT -8

The main benefit is not having to bend over as much to load the fire box.

|

|

|

|

Post by hof on Nov 23, 2019 16:02:56 GMT -8

I'm in indecision. What if winter will be too cold and power of stove will not be enough? That if I calculate wrong sistem\bell size? May I fire stove three times a day?

I think, if it is going to be too cold, provision, I may preliminary insert one-to pipes from bottom to top of stove to circulate air, making stove give more heat and colding bell faster. That do you think?

|

|

|

|

Post by hof on Nov 24, 2019 1:42:46 GMT -8

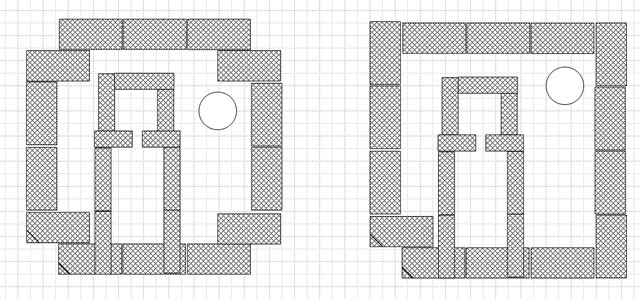

Why do everyone makes sidewinders turned right, not left? |

|

|

|

Post by peterberg on Nov 24, 2019 2:26:39 GMT -8

I'm in indecision. What if winter will be too cold and power of stove will not be enough? That if I calculate wrong sistem\bell size? May I fire stove three times a day? It's not uncommon to run the heater with two loads back to back, twice a day. Back to back is one load burning to coals and dying down a bit, then refilled with really big shunks and letting it go again. That said, it's perfectly possible to run it all day long, just adding one or two pieces at the time. Thermal stress on your heater will be tremendous and some bricks might start to wander off place. No particular reason why most sidewinders are right handed. Left-ish will work as well, the fire don't know about left or right, just about stream patterns and turbulent mixing. |

|

|

|

Post by peterberg on Nov 24, 2019 2:33:31 GMT -8

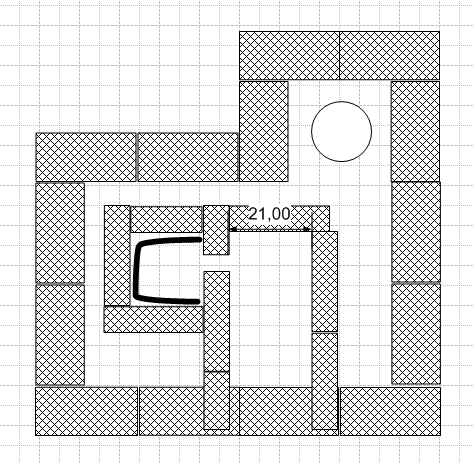

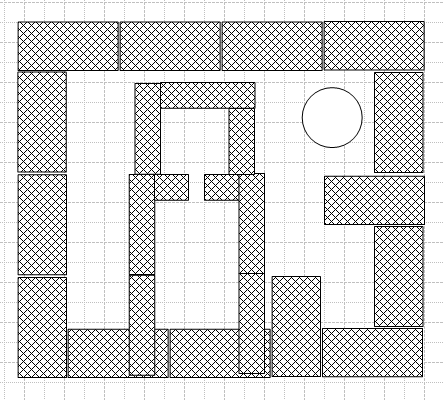

I just spotted a possible blooper in your drawings. You are planning to have the vertical exhaust channel in the shape of a chimney pipe inside the bell, yes? In that case either the pipe need to be insulated or build the channel out of bricks in one corner. Your last bell shape is smaller than earlier, please don't make it too small.

You are building in a workshop, or so it looks like. Be sensible, place the core 50 cm from the floor so you won't have to bend over every time you want to fill the firebox. Gases will go down lower than the firebox anyway. It's done before, my red bell is an example, the workshop barrel tower and all three open systems published to date on the batchrocket website are working this way.

|

|

|

|

Post by hof on Nov 24, 2019 3:18:49 GMT -8

In that case either the pipe need to be insulated or build the channel out of bricks in one corner. Your last bell shape is smaller than earlier, please don't make it too small. Greeting, master! I will isolate pipe, of course. Bypass planning. Last bell shape is BIGGER then earlier, actually. I'm trying to make it powerfull enough, but not looking too big, becouse workshop is not so big. It is 48 meters square, two levels... Today I calculated heat power, needed for heating workshop. It ranges from 2500 Vatts in -10C to 3000 Vatts in -20C. So 150 mm sistem with bell with 5 meters ISA and power radiating 1.9 Kwt is not enough, right? I have got no more room for building 175 or 200 mm sistem. May I build bell bigger, sort of ISA 5.7 or 6.5 square meters and to fire it more than 2 times a day? Firing to times a day means run two loads back to back, twice a day? Four loads, totaly? 4x6=24 kilos of wood? You are building in a workshop, or so it looks like. Be sensible, place the core 50 cm from the floor so you won't have to bend over every time you want to fill the firebox. Gases will go down lower than the firebox anyway. It's done before, my red bell is an example, the workshop barrel tower and all three open systems published to date on the batchrocket website are working this way. Does not stove sucks layer of cold air if firebox placed lower? May I add more bricks inside to give more mass and ISA for stove? Height of stove inside is 1,9 m. Calculated ISA 6,6 m2  |

|

|

|

Post by hof on Nov 24, 2019 4:11:13 GMT -8

? Left bottom corner, if making stove bigger, need to cut for passage. |

|

|

|

Post by peterberg on Nov 24, 2019 8:24:13 GMT -8

Hmmm... You could extend the ISA of that bell, of course. And firing the heater all day long or, two even three double firings per day. The downside is that you need to operate the bypass very carefully. I would recommend to place the bypass at halfway height of the bell, certainly not at the top. In the layout you've drawn, the core need to be elevated from the floor in order to provide enough space underneath it. Placed on the floor, the left hand side of the bell wouldn't get that hot because of a too small passage behind the core so good bell stratification isn't ensured.

You are building in a workshop, are you sure you'll use this shop seven days a week? In case you aren't, it would be a better option to only heat when you are there and build a three-barrel heater like my former workshop heater. I've had several different large masonry heaters for 20 years and only the last two years a "quick and dirty" barrel system. That last one solved my heating issue much, much better. Entering a stone cold shop and starting the heater would mean warming up comes up in 10 minutes. In the case of a brick mass heater that would take at least 24 hours.

|

|

|

|

Post by hof on Nov 24, 2019 10:40:16 GMT -8

Hmmm... You could extend the ISA of that bell, of course. And firing the heater all day long or, two even three double firings per day. The downside is that you need to operate the bypass very carefully. I would recommend to place the bypass at halfway height of the bell, certainly not at the top. In the layout you've drawn, the core need to be elevated from the floor in order to provide enough space underneath it. Placed on the floor, the left hand side of the bell wouldn't get that hot because of a too small passage behind the core so good bell stratification isn't ensured. You are building in a workshop, are you sure you'll use this shop seven days a week? In case you aren't, it would be a better option to only heat when you are there and build a three-barrel heater like my former workshop heater. I've had several different large masonry heaters for 20 years and only the last two years a "quick and dirty" barrel system. That last one solved my heating issue much, much better. Entering a stone cold shop and starting the heater would mean warming up comes up in 10 minutes. In the case of a brick mass heater that would take at least 24 hours. I almost live here, in workshop. 10-12 hours/6-7 days. If not me, my worker works. I've got two workshops, connected each over. One - with insulation inside, it has no mass to hold heat (except two steel lathes) and becomes with barrel heater too hot too quickly and becomes cold fast too. Another one has insulation outside and has much mass brick walls for heating/cooling and two barrel heater works the best. Well, may be smaaaall brick case or column will make stove better, but not nessesery. It has 130 mm system. Yep, I'm firing two stoves at one time. How much height under core need to make? 12 sm, 25, 37? By the way, what distance between pipe and floor need to make?     |

|

|

|

Post by peterberg on Nov 25, 2019 7:07:07 GMT -8

How much height under core need to make? 12 sm, 25, 37? In your case, I would say 25 cm would be adequate. A steel pedestal is close to ideal, otherwise you need to make tunnels by building narrow pillars of bricks to placed the core on. By the way, what distance between pipe and floor need to make? I think you mean the upstream pipe inside the bell? I'd say at least 15 cm when placed in a corner. |

|

|

|

Post by hof on Nov 25, 2019 7:27:18 GMT -8

"At least"... Less then 15, or more then 15?

|

|

|

|

Post by hof on Nov 25, 2019 8:54:55 GMT -8

Have found this file:

batchrocket.eu/images/rockets/files/Batchrocket_mass_heater_sizing.xlsx

Thery useful! Now I undestood that is back to back firing.

|

|

|

|

Post by peterberg on Nov 25, 2019 13:12:01 GMT -8

"At least"... Less then 15, or more then 15? At least means minimum. |

|