|

|

Post by matthewwalker on Apr 5, 2019 9:44:27 GMT -8

Very nice work Peter. It's remarkably stable even with very different fueling schemes and seems to hold up amazingly well to low O2 events. Quite impressive!

|

|

|

|

Post by peterberg on Apr 5, 2019 10:43:44 GMT -8

Very nice work Peter. It's remarkably stable even with very different fueling schemes and seems to hold up amazingly well to low O2 events. Quite impressive! Thanks Matt and pdk17 for the compliments. Yesterday I tried twice to trip the thing into thermal overdrive but it wouldn't. Of course it can be done but to date everything what I throw at it is accepted. Morning run was loaded with pine lumber scraps, reasonable tightly loaded and pieces flat against the sides in places. Usually this slows down the fire development. Just to find out how far I needed to go before things would go the wrong way. Loaded like this: pberg0.home.xs4all.nl/pictures/dev2018/DSR2/04042019.JPGDevelopment was slow as expected and it made a nice diagram without exiting moments. Averages: O² 14.0%, eff. 87.5%, CO 555 ppm, stack 127.6 ºC.  Evening run was loaded with about the same weight and species but with more air spaces. Also not as much touching the sides so lots of air could stream around it.  I let it run quite a bit longer with lots of air, akin to a door that was open considerably more than a crack. And brought it back to a slightly smaller size than normal around the 10 minutes mark.  As one can see oxygen went down quite far in the danger zone below 6%, 3.8% to be precise. CO reacted by rising up to 1000 ppm and that was it. So despite not being a nice run it stayed within specs easily. Averages: O² 11.4%, eff. 90.2%, CO 643 ppm, stack 126.4 ºC. Top stack temperature (170 ºC) could be quite a bit lower, something between 100 and 120 ºC would be enough. At this stage I am confident to declare this core as a robust and reliable combustor. Making plans to rebuild the entire thing in firebricks or refractory castable is now in order. New reports of test runs will be some way off now, unless I stumble over other nice-to-tell items. Like... run the darn thing as an open fireplace and see what happens? |

|

|

|

Post by peterberg on Apr 6, 2019 7:25:43 GMT -8

About 20 hours ago I wrote: "Like... run the darn thing as an open fireplace and see what happens?" That's exactly what I did, last night. After dark, so I wouldn't embarrass the neighbours in case the thing would smoke like mad... To my surprise, it didn't. In fact, there were some differences as compared to earlier burns but not that significant. To be honest, judging the diagram on its own I wouldn't guess it was run without a door. The top end of the CO line was around the 10 minutes mark, 904 ppm. Right after I added a piece of fuel to the already healthy burning pile. Stack temp was higher, highest moment just touched the 200 ºC level. I have to admit the firebox wasn't filled up completely, but still this burn left me quite puzzled once it was over... See the diagram for yourself. Averages: O² 13.8%, eff. 85.8%, CO 404 ppm, stack 146.2 ºC.  And how it was loaded.  Before anyone asks: yesterday the secondary air channel was plugged up. Today I took out the floor channel and turned it over so the vertical stub is hanging down from the front now. I plugged up in front of the port and spreaded a nice layer of ashes over the steel duct. I will be able to run it again tonight using a spark screen in place of the glass. The oven part is still closed with a piece of glass by the way. It's getting stranger by the day... |

|

|

|

Post by martyn on Apr 6, 2019 7:56:19 GMT -8

Burning it without a door puts a whole new perspective on the design!

Are you saying it could be lit and run a full burn without a door?

|

|

|

|

Post by peterberg on Apr 6, 2019 8:51:07 GMT -8

Burning it without a door puts a whole new perspective on the design! Are you saying it could be lit and run a full burn without a door? Yes, that's what I meant. I may add there's a good chimney behind it, it draws right from the start. |

|

|

|

Post by independentenergy on Apr 6, 2019 11:43:38 GMT -8

this project is increasingly surprising

|

|

|

|

Post by drooster on Apr 6, 2019 13:29:12 GMT -8

The ultimate fireplace!

*look of awe*

*strokes beard*

|

|

|

|

Post by peterberg on Apr 7, 2019 8:37:08 GMT -8

The ultimate fireplace! *look of awe* *strokes beard* I would like to add: *scratch head* That's what I did last night, while running this thingy as an open fireplace (again). A spark arrestor in front because with coniferous fuel sparks *do* fly. Loaded nearly full, mainly small scraps, some dry thinly split willow at the bottom and lots of air between pieces. Very interesting in the sense that development of the fire happened to be very quick and duration very short. This is the type of load which I would classify as "fat chance for failure". In a way, it did but in a very subdued manner and as it is, still within reasonable specs.  As can be seen, CO peaked to almost 2000 ppm at 21 minutes and that was it. Within two minutes it corrected itself, end of burn at 29 minutes. Such a quick burn usually lead to an awfully hot barrel: 280 ºC (536 ºF) at the side, 10 cm (4") from the top ridge. Coupled to high end temps, 220 ºC (428 ºF) in this case. The draft limiter is an indispensible tool while running a test like this, it prevents soaring draft. Averages for this burn: O² 10.9%, eff. 88.8%, CO 468 ppm, stack 151.4 ºC (305 ºF). As far as I can see, it would be hard to coax it into a fuel overload. Which is what I was aiming for after all. Tonight or tomorrow I'll try a last run using some medium sized pieces of oak and beech to close it off for the season. It's time to think about the next phase, building a reference model. |

|

|

|

Post by Karl L on Apr 7, 2019 11:47:56 GMT -8

Peter, do you have time to sketch a cross section of the top box?

I don't understand the position and size of the brick that descends from the ceiling of the top box from the written descriptions.

|

|

|

|

Post by drooster on Apr 7, 2019 15:02:04 GMT -8

I agree with Karl.

(!There's a rip in the space-time continuum!)

|

|

|

|

Post by hallinen on Apr 7, 2019 19:28:03 GMT -8

Why is the oxygen dropping down so low if there isn't a door? I'm confused about the floor channel. Was there secondary air flow?

Is the ripped space-time continuum sucking the oxygen to some other dimension?

Thank you so much for publishing these graphs. It really is fascinating.

|

|

|

|

Post by peterberg on Apr 8, 2019 2:27:09 GMT -8

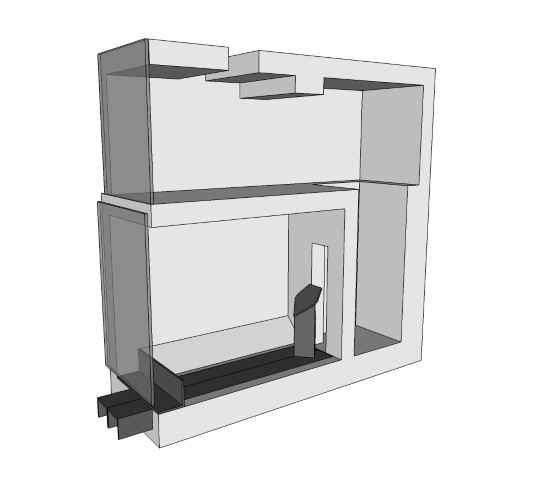

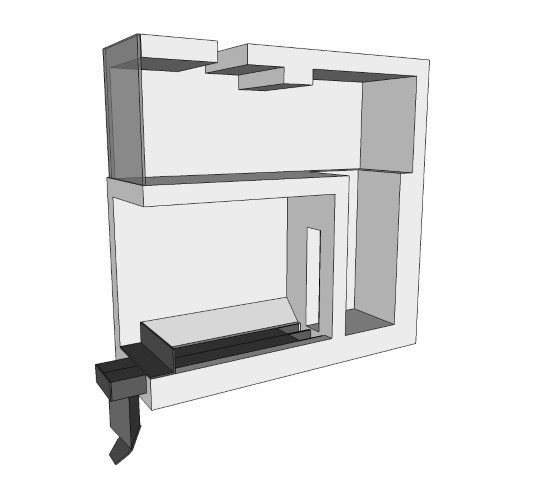

Peter, do you have time to sketch a cross section of the top box? I don't understand the position and size of the brick that descends from the ceiling of the top box from the written descriptions. While I am at it, drawing a lengthwise cross section of the whole core seems to be the best way. The first one is the situation complete with glass panels and enlarged floor channel. The brick hanging down is the ridge at the ceiling, parallel to the front.  The other one is amended in such a way the floor channel stub isn't in front of the port while there isn't any air streaming through. Of course I plugged up the floor channel in front of the port, with rockwool and ashes on top.  The floor channel isn't doing anything, it's just a quick way to fill the trench with a dormant object. |

|

|

|

Post by peterberg on Apr 8, 2019 3:29:36 GMT -8

Why is the oxygen dropping down so low if there isn't a door? I'm confused about the floor channel. Was there secondary air flow? Second question is easy to answer, it's no, not at all. First question is a good one. I'm not sure about what is happening exactly but I can provide an educated guess. With a door, there's a limited stream of air through the firebox, caused by the chimney draw and amplified by the venturi of the port. In front of the box is atmospheric pressure, at the back there's under pressure, i.e. a limited vacuum. So air is drawn through the box by the pressure difference. Blowing the flames to the back and cooling the front end. Since the primary air inlet is restricted the cooling effect is lower. The blowing effect is also lower but both these effects aren't linear or even congruent. Restricting the air flow means less cooling of the fuel/fire mainly. So temperature in the firebox goes up, causing the fuel to off-gas at a higher rate. As a consequense, in order to ensure the afterburner function working properly secondary air need to be applied. This can be done in a number of ways but its function remains the same. Resulting in a quite violent burn and high temperatures in the afterburner area (port/riser). Restricting the primary air too far the cooling function caused by the air blowing in is deminished and there isn't enough oxygen anymore to keep flames going in the firebox. At the same time there's lots of wood gas produced due to the elevated temperature so the resulting overload of burnable gasses chokes the afterburner function. A lot of those burnable components won't be reached by the oxygen anymore and this results in black smoke out of the stack. Now an open system, specifically the one I am currently working on. Same situation as above, lots of air is rushing in and cooling as well as blowing through the fire causing high temperatures in front of the port. Air is also streaming over the fuel so in this situation it's imperative a gap is left open between fuel and ceiling so air is able to reach the port. In an ideal situation the cooling and blower effects keep each other in balance but most of the time it isn't. The blower effect would win, leading to higher and higher draw, rate of off-gassing goes up and an overload is imminent in the majority of cases. This is mainly due to the fact the venturi air speed goes up tremendously, almost unlimited. In this particular core there's a difference though: the air velocity in the port is limited by the second port, the top exhaust. Assuming this is working as I think it is, pressure difference between the front of the firebox and the rear won't run out of hand. Cooling function doesn't go down and blower function doesn't go up that much. The air streaming over the fuel is still able to reach the port to contribute to the afterburner function. The latest diagram shows an overfuel situation (or thermal overdrive) is still possible. But one has to do his or her utmost best to get it that far. No ripped space-time continuum just old-fashioned physics, in my humble opinion. Another effect might be in play also: part of the oxygen could be excluded by the overload of hydrocarbons. Which could explain why oxygen is going that low in an open system. Sitting in front of the thing and seeing the open fire grow while there's no smoke at all from the chimney is really surprising. It looks like an open super-duper-fireplace! |

|

|

|

Post by hallinen on Apr 8, 2019 14:23:52 GMT -8

Thank you Peter! Excellent explanation. I want a super-duper-fireplace!

|

|

|

|

Post by DCish on Apr 8, 2019 15:32:35 GMT -8

Been outdoors since spring hit, but so glad I checked back in! That the second port / restriction (in the right ratio!) has done so much to stabilize the entire burn is thrilling! I can't help but wonder how much of the balance achieved was made possible by the stable draft you have now that you have the draft limiter installed. If that were removed, would the additional draft as it comes up to temp overcome the balance achieved by the dual-port system? Regulating draft might put us one step closer to achieving repeatable results.

|

|