Teach

Junior Member

Posts: 89

|

Post by Teach on Jan 28, 2009 18:27:02 GMT -8

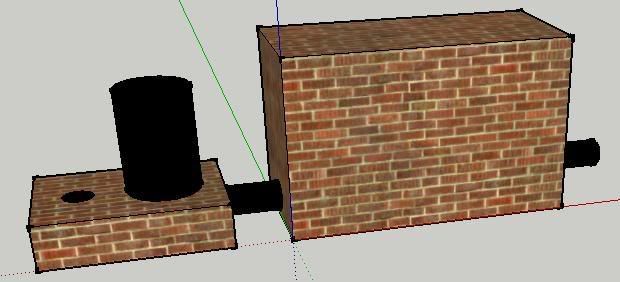

Just to take away any guessing as to what it is I am thinking of doing I drew up this image of what the unit would look like complete. The exhaust goes to the chimney. I could not figure out how to put an elbow into it to illustrate it. Internal workings of a standard rocket stove apply in the photo. I'd love to hear from you all as to how this thing would perform if built with an all brick version replacing the barrel as well but keeping the bell. I think the bell could be larger than the one for a heater using a barrel because less immediate heat would be released sending more to the bell. Peter, looking at this picture.............do you still think I would only need 40-50 cubic feet within the bell for a setup like this?  Comments please! Teach... |

|

|

|

Post by peterberg on Jan 29, 2009 10:22:47 GMT -8

Peter, looking at this picture.............do you still think I would only need 40-50 cubic feet within the bell for a setup like this? Teach, Please compare it to a stove pipe in a bench system, 8" across and 40' long. That'll equal 13.96 cubic feet, unless I am seriously mistaken. So I think 40 cubic feet inside the bell is the absolute maximum. You are even running the risk the bell would be too large. The bell is better at taking up heat, but there is less friction compared to stove pipe. Besides that you'll need a bypass and/or primer box with such a system. |

|

Teach

Junior Member

Posts: 89

|

Post by Teach on Feb 8, 2009 18:00:11 GMT -8

Thanks Peter, I am re-thinking everything size wise.

When calculating the cubic feet of the bell my first inclination is that it is only the internal volume being calculated and not the external. But because we are dealing also with thermal mass here it makes me wonder if you might have been referring to outside dimentions of the bell.

When you stated the number of cubic feet the bell should contain, were you referring to inside or outside dimentions?

If I built the rocket as above entirely of brick, it would not give off as much radiant heat as one that used a barrel. Because it would have more push as it were, I'm thinking it could feed a larger bell than a model with a barrel correct? (in theory)

I am probably going to build the bell somewhere close to the dimentions of 24"x30"x60" for a total volume of 25 cu. ft. and an internal volume of roughly 10.2 cu. ft. assuming the bricks are 2x4.5x9" and I use them on the flat. At this size I'm thinking I should be safe based on your recommendations and that you were referring to internal dimentions and not external when referring to the bells volume.

Teach....

|

|

|

|

Post by peterberg on Feb 9, 2009 12:14:34 GMT -8

...When you stated the number of cubic feet the bell should contain, were you referring to inside or outside dimentions? The volume I am referring to is always inside. In theory, that's correct. So, when you are calculating the total volume, first and second bell together, try to end up with a figure that is around 40 cubic feet max. My 6" double bell system had a total volume of 25 cu feet and produced a very low output temperature. Approximately 104 F for the first 60 minutes, starting from cold. Yours would be an 8" system, about 1.77 times as large as mine. The volume multiplied with 1.77 makes 44.25 cu feet. Regard that as a maximum without safety margin. |

|

Teach

Junior Member

Posts: 89

|

Post by Teach on Feb 9, 2009 16:15:08 GMT -8

I'm getting confused here and I think what is happening is this;

You given me volumes for an 8" system for a maximum volume of 40 feet within the bell based on the sizing up of the 6" system you built with the combustion chamber within the bell. Yet previously you stated for me to consider 13.96 cubic feet as the example of a bench style battery for comparison.

If I have understood this you are stating that 13.96 cubic feet is a max bell size to be used with a rocket heater utilizing a barrel ?

And 40 cubic feet for an 8 inch system with combustion chamber within the bell ?

Most bench style rockets vent through a wall directly after leaving the bench and most don't have 40 linear feet of pipe within them (usually less) and they have only warm and moist air exiting the flue outside. Determining the size of a bell to replace the bench and yet still have enough heat left in the gasses to push them up my chimney is going to be a challenge.

I am starting to think that I should perhaps do one of two things;

First option, build a rocket heater with barrel and connect it to my chimney with no bench or bell or;

Second option, build a rocket within a bell similar to your first example Peter.

I am thinking that trying to do a system with the features of both wont have enough heat left in the gasses to work with my chimney unless I push a low short chimney out a basement wall/window and then brick it in around the pipe. Thoughts?

Teach....

|

|

|

|

Post by Donkey on Feb 10, 2009 8:17:04 GMT -8

What I recommend against is building a rocket stove (for heating) with just a barrel and no heat storage of any kind. You would gain no particular advantage, just more efficiently pump heat to the outside world.

You could somehow place the barrel or the burn tunnel close to the chimney so that some of the heat leaks through the thermal mass to drive the draft.

Things may need to be rotated somewhat for everything to fit, you may need to pipe around a corner before going up the chimney or some such.. Also, I would make any thermal mass between the heat source and the chimney rather thin, or have the barrel actually touching the chimney in places or something..

It is possible that you could build a rather too large bell system and still get correct flow in this way.. ??

|

|

|

|

Post by peterberg on Feb 10, 2009 11:46:53 GMT -8

You given me volumes for an 8" system for a maximum volume of 40 feet within the bell based on the sizing up of the 6" system you built with the combustion chamber within the bell. Yet previously you stated for me to consider 13.96 cubic feet as the example of a bench style battery for comparison. What I mend to say was: don't go over the top, see what small a bench is compared to a single or double bell. Volume of the smoke path, that is. Yes. So I thought: it would be best not to get the bell too large. Please don't. That one would be nice. But I am preaching for my own parish now. |

|

Teach

Junior Member

Posts: 89

|

Post by Teach on Feb 10, 2009 13:06:40 GMT -8

Donkey, with regard to no advantage other than efficiently pumping heat up the chimney............I hear what you are saying...........thats what my box stove does now...........but my main reason for wanting to go the route of a rocket style heater was to gain the ability to clean up my wood burning emissions instead of spewing forth smoke like my box stove. I'd be willing to do that for the environment in exchange for having to fiddle with the fire more.

With every question answered I get much closer to going ahead and starting to build. I will have to give some thought to the barrel close to the chimney. Might have some merrit there. I've got two cleanouts at the base of the chimney that I have to work around. What ever I build still has to allow access to those clean outs. I appreciate everyones input.

Peter..............If I join your parish, will I get to do fun stuff like sing and burn things? grin! Thanks.

|

|

|

|

Post by johndepew on Feb 18, 2009 13:05:47 GMT -8

Okay, any ideas on how to incorporate an oven compartment into a bell stove like this? I'd like to be able to bake inside. Originally my idea was just to put a closed compartment right close to the junction of the heat riser and the exit flue, hoping I'd be able to harvest enough heat from two sides to heat the oven up to baking temperatures on a standard Evans top feed rocket. I mentioned this to Donkey, and he recommended something more along the lines of a bell design with an oven compartment in it or something to that effect. Advice?

John

|

|

Teach

Junior Member

Posts: 89

|

Post by Teach on Feb 27, 2009 12:59:37 GMT -8

Peter, in an earlier post you said there must be a minimum distance of 3 feet between the top of the riser and the underside of the top cement pavers. Why is that.................because the cement cant take the heat if closer? Could a person use refractory castable and have a lesser clearance because the refractory can take greater heat? Thanks

|

|

|

|

Post by peterberg on Feb 28, 2009 10:14:37 GMT -8

Teach, the clearance of 3' is for the ordinary pavers only.

When you are using refractory castable instead, the minimum clearance mentioned in Evans' book applies. Normal pavers are 2" or something like that, I am using the same thickness in my last experiment.

|

|

Teach

Junior Member

Posts: 89

|

Post by Teach on Mar 10, 2009 7:56:41 GMT -8

Does anyone know of someone who has had any experience using stone and cement to construct a bell?

Bricks are mighty pricey here and rock is something we have noooooooo shortage of.

Donkey, do you think there is any reason why a person could not utilize a bell and still run the exaust pipe horizontally like a standard rocket and bench style where the flue pipe exits through an external wall?

If so, and you had a continuous slow but steady drop in the pipe so condensation could run out downhill..........you could essentially take all available heat out of the gasses yes?

Teach....

|

|

|

|

Post by Donkey on Mar 11, 2009 5:25:30 GMT -8

Donkey, do you think there is any reason why a person could not utilize a bell and still run the exaust pipe horizontally like a standard rocket and bench style where the flue pipe exits through an external wall? If so, and you had a continuous slow but steady drop in the pipe so condensation could run out downhill..........you could essentially take all available heat out of the gasses yes? Teach.... Yes, theoretically you could do this. A word of caution though.. You couldn't use a chimney with the stove. Your flue gasses would need to pour out onto the ground and flow away. This places possible poisons down at your level, where you or your neighbors could come in contact with them.. |

|

|

|

Post by canyon on Mar 11, 2009 8:17:55 GMT -8

The whole idea of free gas movement with a bell system seems to me to somewhat cancel the positive pressure generating concept of the "internal stack" (also known as the heat riser) that allows for significant horizontal runs. This is something I have thought about occasionally the past few months and was going to post a discussion on. I'm glad it came up. I think you would need to rely on a warm stack at the exhaust to draw the gasses through a bench after a bell thus needing a few hundred degrees F remaining? This could be outside and even terminate under the eave like in the book but I would want the stack to be of the insulated variety and it would need a primer hole/clean out to get the thing going when cold. To turn a classic rocket/bench system into a condensing version I think you'd have to forego the bell. If I had plenty of rock like you, I'd definitely use that for the mass battery. I strongly advocate for working with what you have. I'd work my design accordingly. Also, where you can do without cement saves you and the rest of the planet.  |

|

Teach

Junior Member

Posts: 89

|

Post by Teach on Mar 11, 2009 9:02:03 GMT -8

Building from scratch is sooo much easier than trying to remodel isn't it!

The other night I was laying in bed still contemplating the build of the rocket bell in the basement. It would be so much work only to find that it had troubles and then the thought came to me to build a rocket in my built in garage - no chimney to deal with!

Some ideas were close to 40 feet of single pipe in a 2x2 foot battery along the perimeter of the shop along the base of two walls. I even wondered about building an open bell built out of stone masonry over top of the standard rocket with barrel just to act as a heat sink close to and surrounding the barrel and take the flue gasses off in the usual manor as per a bench(less instant heat/greater storage. The gasses would come through a wall close to the ground and empty into full wind exposure around the side of a paved driveway. Only time anyone is around that area is walking to or coming from our vehicles. Chances are no one would be coming or going when the stove is still burning anyway. I think that should serve the purpose ok.

Donkey, in your opinion - what would be an acceptable steady drop for the stove pipe over 40 feet? Keep in mind this will be a larger than 8 inch system. Any surplus heat (if it gets too warm in the shop) I will dump into the house and still be ahead of the game.

Canyon, I understand what you are getting at. I'm not sure I see the need for concern though. Everything I have read and heard about with regard to rockets is they need a good seal to work their best and not poison the person using them with bad gasses leaking out of them because they are pushers of the gasses. They don't require any draft except from the riser to work properly. If you think about it, a barrel is nothing more than a bell on the rocket that radiates heat more than brick does and at higher temps. I can see differences in performance because of cooling rates of the gasses but as long as your riser tube is tall enough you should be able to push those gasses a long way like 20-30 feet with a 6" system and 30-40 feet with an 8" system. I have not heard of anyone so far building a system larger than 8" which is what I am hoping to do. I will need to play around with the bricks and see how easy it is to do without requireing twice the number of bricks etc. I too am thinking along your lines of using what I have got. I have lots of rock but next to nothing for clay. The whole area seems like one giant gravel/rock pit.

|

|