Post by fiedia on Jun 14, 2021 7:53:21 GMT -8

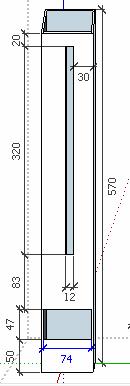

I built a 5” batch prototype with air inlet in the door frame as per Peterberg design for his DSR2. The primary air flows through the frame and penetrates the firebox on each side of the door. The air flow along the door minimizes deposit on the glass. Details can be found: here

On Peterberg advice, I did some trials reducing the primary air inlets to improve burn stability and reduce thermal overdrive occurrences.

Four different setups were tested:

- no tape on the inlet slots (20.4cm², i.e. 16.6% of HR CSA)

- 50mm tape on the inlet slots (14.4cm², i.e. 11.7% of HR CSA)

- 70mm tape on the inlet slots (12.0cm², i.e. 9.8% of HR CSA)

- 90mm tape on the inlet slots (9.6cm², i.e. 7.8% of HR CSA)

the tape is stuck at the bottom of the slot.

The secondary air inlet (floor channel) is not changed (11.96cm² i.e. 9.7% of HR CSA).

Results :

With usual wood loads (medium size logs), the burns were more stable with 50mm and 70mm tapes. For 90mm tapes, it would burn badly and create dirty smoke unless I left the door slightly open.

A potential explanation is:

- With full inlet opening (24.4cm²), smokes come from thermal overdrive. The wood load is getting too hot. HR temperature is high enough to create post combustion but there is not enough air to burn all gases generated in the firebox.

- With 90mm tape: there is not enough air to generate high flames. The HR temperature is too low to start post combustion.

- with 50mm tape: the fire is more stable than with no tape but thermal overdrive occurred at the end of the burning phase.

- with 70mm tape: the fire was stable and clean during the whole burning phase.

The curves below show the temperature at the hottest point of the HR (bottom) for each inlet setting.

The 70mm tape setting gives the best results. I tested this setup with different types of wood.

- mix of medium size hard wood (50mm) and split pine boards (20mm): the fire lasts 40mn with temperatures between 600 and 700°C and absolutely no smoke.

- exclusively big logs of hard wood (80mm): temperature stays around 500°C during almost one hour. It is quite low but sufficient to start post combustion since no smoke is generated.

- exclusively split pine boards (20mm): temperature stays just below 800°C during 30mn. Thermal overdrive occurs after 15mn.

In conclusion, the 12cm² setting (10% of HR CSA) is much more stable than the initial opening (20cm²). Big logs burn without generating smoke. Thermal overdrive occurs only with thin split pine boards.

Now I wonder where is the best place for the inlet slots. It seems that the fire quality is improved when there is more room between the firebox ceiling and the wood load. Does it mean that it is better to have the air flow above the fire ?

peterberg , you have tried with a slot on top of the frame. Did you notice an improvement ?