zoska

New Member

Posts: 12

|

Post by zoska on Aug 13, 2016 9:51:15 GMT -8

I'm in the process of building a 8" batch rocket mass heater with a single bell and would like to add an pizza oven. I've gone thru some of the pizza oven threads but they all seem to oriented toward outdoor/black systems whereas mine will obviously be indoors. The barrel oven will be about 350-400 x 700 x 360. The oven floor will be firebrick and the walls and roof will either be cast refractory or firebrick as well. Unlike a typical black pizza oven, there will be no insulative outer shell needed to keep the heat from escaping thru the walls as it'll be inside the top of the hot bell. The pic shows the 3 design options from the side view My options are 1. insert the oven into the bell with the back section a few cms above the riser thereby heating to floor directly and the rest of the oven will be heated from the "outside" walls in with the heat from the riser circulating around the outside of the oven inside the bell. This option doesn't require a door but it'll probably help keep the heat in during the initial warm up stage then removed for the pizza making, etc My only concern is whether this be sufficient to get the oven to pizza temps of around 400c? 2. insert the oven into the bell with riser coming into the back section and straight out the top, in effect extending the riser sideways. This version will require a sealed door in order to close off the smoke (initial firing), gases and heat from the riser escaping into the room. I'm thinking that this may be a better or more direct way of heating up the oven and should have no problem getting to the required temp? 3. The same as 2 but with the exit toward the front of the oven instead of directly above the riser in order to pull more of the heat from the back of the oven to the front thereby heating it more uniformly? Kinda like a french made gueulard. Thoughts?  |

|

|

|

Post by mkrepel on Aug 14, 2016 15:43:27 GMT -8

Is the riser insulated? I believe it should be as that is a main component of rocket stove combustion. In light of that, I would think option 1 would work the best and is closest to what others have already used with success. However, instead of only directing part of the hot gases through the oven, direct all of them through there and provide another point for exit...possibly under the floor but higher than the burn chamber. If you wish to use this inside, you might want to use a masonry heater approach to heating and use. That is, run the fire to get the high mass oven up to temp. Remove the fire and then start baking. That way, you don't have to worry about opening the black oven while the fire is burning and getting smoke in the room. The other option is to have the chimney directly above the door so that the smoke naturally goes up the chimney, even when the door is open. I believe Ernie and Erika Wisner built something along those lines.

|

|

zoska

New Member

Posts: 12

|

Post by zoska on Aug 15, 2016 12:02:31 GMT -8

I think I'll have to do a sketchup drawing version of my sketch :-D

It's a normal BRMH, so yes, the riser will be insulated.

Option 1, is a single bell with the oven inserted above the riser, so the outer skin of the oven is exposed to the hot gases inside the bell

Option 2 and three change this by having the oven part of the riser and getting the direct riser exhaust circulating and passing thru the inside of the rise. So in effect, heating from the inside (via the riser)and outside (bell) of the oven

The oven will have to have a door otherwise the bell/mass part of the design would pretty much be wasted as a lot of the riser exhaust will be exiting into the house even if there's a chimney at the oven mouth

|

|

|

|

Post by mkrepel on Aug 15, 2016 22:13:44 GMT -8

Okay. I am having a little trouble visualizing, so sketchup would probably work best. Your description suggests you might be thinking about a white oven. That would be the easiest way to ensure you keep smoke out of the room when you need to open the oven. Of course, that also brings up issues with how you get the heat into the oven. Approvecho did some work with a barrel (30 gal)inside a barrel (55 gal) with insulation on the outside. The word is that this arrangement worked very well for cooking pizzas and other baked goods without too much warm-up ahead of time. Since the oven itself was isolated from the flue gases, you would not have issues with smoke in the room. I believe there were some additions later on to add more steel to the area of the inner drum where the flames exited the riser and impacted the inner drum. This area would be very susceptible to erosion due to high heat and oxygen impacting the bare steel.

Of course this would be more of a rocket stove feeding to the underside of an oven than a rocket mass heater. I guess you could still feed the exhaust to a bench or bell for later use after it leaves the oven.

|

|

radek

Junior Member

Posts: 94

|

Post by radek on Aug 16, 2016 3:09:06 GMT -8

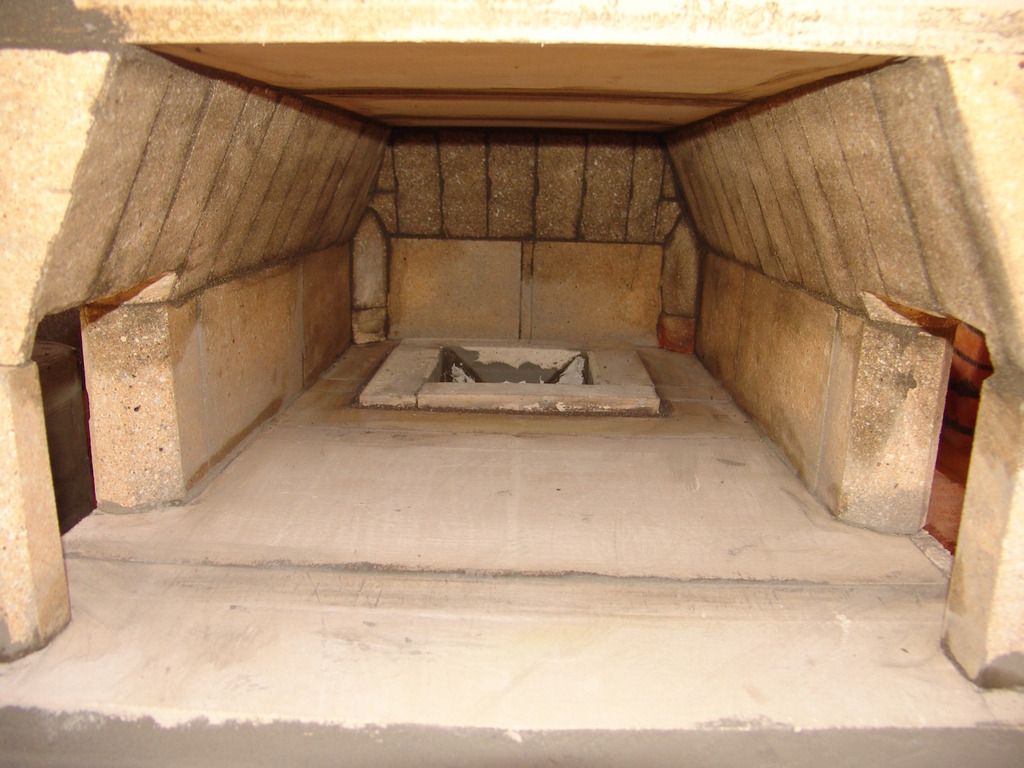

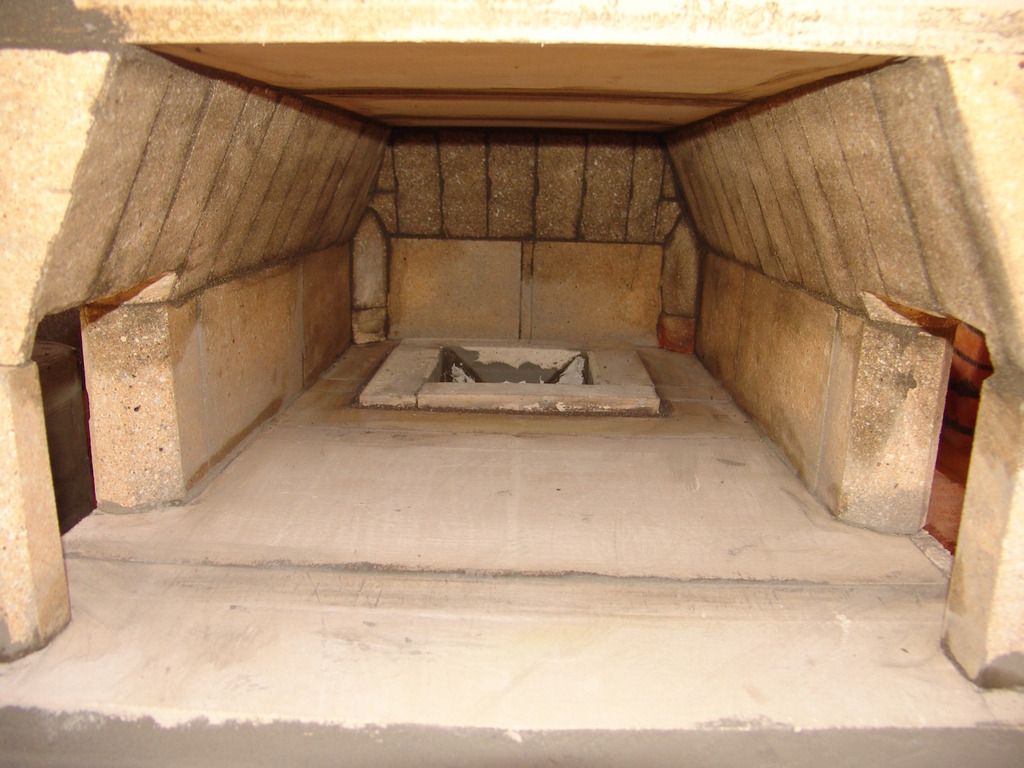

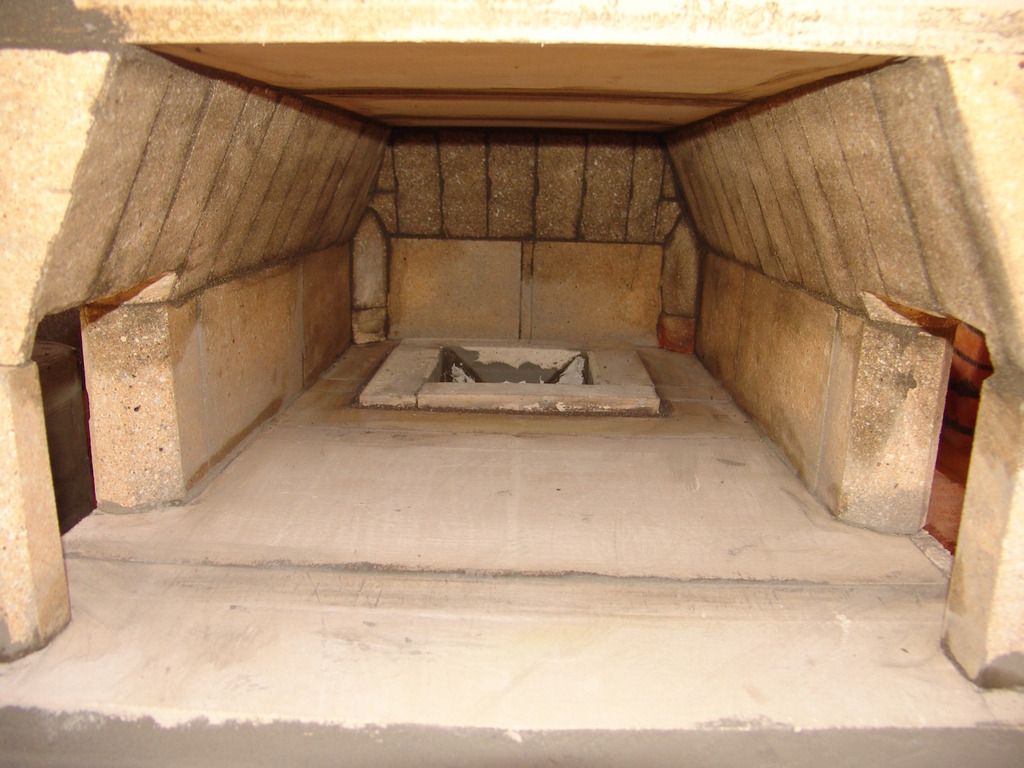

Hi Zoska from yours 3 options ,i would consider the pics #1 and the pics # 3.The picture 1 being a white oven/the gasses are not going into the oven/ i guess you could get 400C if the oven would be a cast iron insert.If you will build the oven body out of fire bricks I'm not sure about the 400C inside the oven.But the main problem with the pics 1 would be the height of the stove.If you wanna lift the fire chamber a bit of the floor of the heater,let say a 30cm above the floor,it would be 30cm+144cm/the heat riser/+30cm/space above the heat riser and under the oven floor/+cca30cm/height of the oven/=234cm to the top of the oven and 200cm to the ovens floor/and i didn't add the thickness of material you be using.You could make the heat riser a bit shorter ,but only if you have a good working chimney.So thats my thoughts to pics#1. The pics # 3 i believe would be a better option /only my opinion/if you don't mind a black oven.I have just build a 8" bachbox heater with black oven above the heat riser so here is a pics of the oven how i did it.Please don't ask me about the heater performance ,it will take a while to build a first fire in it.  |

|

|

|

Post by pyrolyse on Jan 9, 2017 18:46:26 GMT -8

I am looking forward to more insights on this area, it is IMHO one of the really nice features that is commonly added to the contraflow masonry heaters. Also, I think Batch Boxes would appeal to more people, if there were a baking oven option.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Feb 1, 2017 12:59:33 GMT -8

Hi zoska, I think the solution of radek is the best because I tried a white oven somehow like your pic #1 and the maximal temperature "only" goes up to 200-250 °C which is not enough if you want your 400°C. The configuration I tried is an oven resting on pillars above the firebox so that there is plenty of space above the riser. The oven is made of half-bricks 3 cm thick and is heated from 5 sides out of 6. The bell effect is working very well to have an homogeneous heat all aroung the meal that is baking inside the oven. Detailed pictures here : webcloud.zaclys.com/index.php/s/7Dp1eO2OSN0HiBf and sketchup file here : uzume-asso.org/assets/plans_sketchup/batch175_112016.skpradek : What is that build ? Do you have more pictures ?? Regards,  |

|

|

|

Post by martinus on Feb 4, 2017 2:42:27 GMT -8

Hi zoska, I think the solution of radek is the best because I tried a white oven somehow like your pic #1 and the maximal temperature "only" goes up to 200-250 °C which is not enough if you want your 400°C. Hi yasintoda, Eventhough your oven does not go up as high as you would want I am impressed with your build. It looks great! Are the benches warming up nicely? |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Feb 5, 2017 7:25:16 GMT -8

Hi martinus, Thanks for the compliment! The right bench is heating nicely but not not up to the far end where it only is lukewarm. The left bench being closed to the exit is heating very well, and even too much! For now the top is only 3 cm thick, while the sides are 10 cm thick. The clients will add another layer of terracota tiles, which will lower the temperature of the top of the bench and make it more uniform. For zoska, I tried another configuration (I really like ovens in mass heaters) with a white oven heated on three sides only (bottom, rear and top) and got the results yesterday : max temperature is around 150 °C which is a bit disappointing. Good for long, slow cooking but not adapted to the clients.. Pictures :   |

|

grga

Junior Member

Posts: 76

|

Post by grga on Mar 8, 2017 23:32:38 GMT -8

....I have just build a 8" bachbox heater with black oven above the heat riser so here is a pics of the oven how i did it.Please don't ask me about the heater performance ,it will take a while to build a first fire in it.  Hi! Have you try the oven yet? I am wondering if ti gets hot enough at the bottom to bake pizza also from below. If this oven is placed in the bell then gasses in the bell also heat the oven floor from below -so I guess this is fine. I am thinking to build similar oven (similar to the oven design in batchrocket.eu/en/applications) for outdoor which will not be in the bell – I have doubts about the floor getting hot enough. |

|

|

|

Post by suyana on Jun 13, 2017 10:42:37 GMT -8

Hi martinus, Thanks for the compliment! The right bench is heating nicely but not not up to the far end where it only is lukewarm. The left bench being closed to the exit is heating very well, and even too much! For now the top is only 3 cm thick, while the sides are 10 cm thick. The clients will add another layer of terracota tiles, which will lower the temperature of the top of the bench and make it more uniform. For zoska, I tried another configuration (I really like ovens in mass heaters) with a white oven heated on three sides only (bottom, rear and top) and got the results yesterday : max temperature is around 150 °C which is a bit disappointing. Good for long, slow cooking but not adapted to the clients.. Pictures :   Hello I am about to build a BBR 8" with an oven. I really like this model. Is it working well? Can you send me the link with the pictures again because I can't get to open it? Do you have a plan drawer? Do you have any other BBR with oven configurations to give me inspiration? Thank you Noa |

|

|

|

Post by satamax on Jun 13, 2017 11:29:25 GMT -8

|

|

|

|

Post by suyana on Jun 14, 2017 11:32:33 GMT -8

Thanks! Do you have any pictures of it done? Or you didn't build it yet? |

|

|

|

Post by jliebler on Jun 14, 2017 17:15:20 GMT -8

I think I'll have to do a sketchup drawing version of my sketch :-D It's a normal BRMH, so yes, the riser will be insulated. Option 1, is a single bell with the oven inserted above the riser, so the outer skin of the oven is exposed to the hot gases inside the bell Option 2 and three change this by having the oven part of the riser and getting the direct riser exhaust circulating and passing thru the inside of the rise. So in effect, heating from the inside (via the riser)and outside (bell) of the oven The oven will have to have a door otherwise the bell/mass part of the design would pretty much be wasted as a lot of the riser exhaust will be exiting into the house even if there's a chimney at the oven mouth My vote is for option 1 but modified! First some observations: There needs to be space above the riser for the gasses to move with minimal restriction, Peter has said this needs to be 12 inches for a 6" system 16 inches or more for 8". The top of the riser, for an 8 inch system, is almost 5 feet above the firebox floor. Putting the oven floor over 6 feet above the firebox floor. To me the solution is to abandon the idea of putting the oven above the riser, placing it beside the riser, possibly with it's top about level with the top of the riser. The second half of the solution is to insulate the inside of the bell above the oven floor or even down a few inches below the oven floor. Now the insulated insides of the bell do NOT count as ISA and will conduct minimal heat away from the gas stream while the oven's top,back,sides and even bottom do count as ISA and will all store heat taken from the gasses, thereby heating the oven. |

|

|

|

Post by satamax on Jun 15, 2017 13:59:34 GMT -8

Thanks! Do you have any pictures of it done? Or you didn't build it yet? Just planning. |

|