Post by Donkey on Nov 12, 2009 9:35:45 GMT -8

I've recently been turned on to adobe brick for quickly building stove parts.. Adobe is just cob, stuck in a form and allowed to dry.

So I thought that (just for fun) I'd try building the standard rocket J tube out of adobe brick.. Just to add a little twist, I've made a few out of rice hulls and clay slip. These extra light, insulative bricks I've placed in the hottest part of the heat riser, the bottom half.

Here's my usual test bed, showing the adobes in the background.

Here are the two types of brick I made. On the left are the rice hull bricks and on the right, standard adobe.

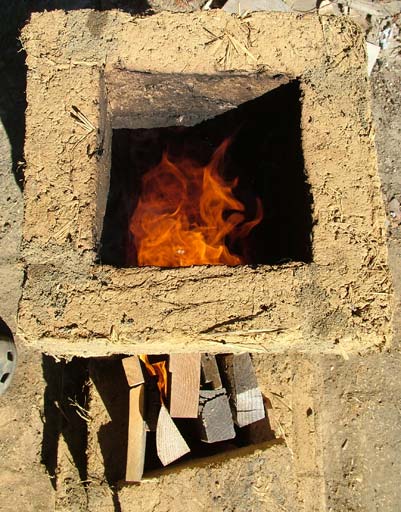

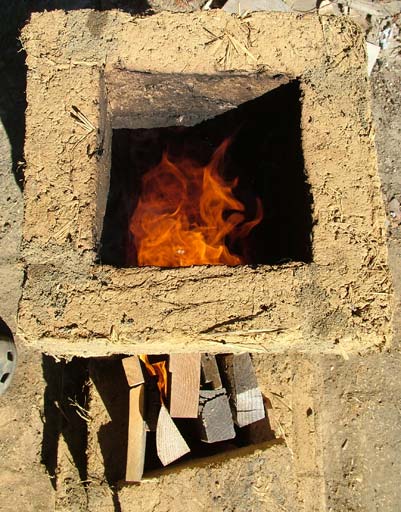

And here is the J tube stuffed with wood and burning, you can't see any smoke.

It burned VERY HOT. It isn't in this image, but at one point there was flame shooting about a foot out of the top.

After the fire burned down and it was mostly cool enough to handle , I took it all apart to see how the bricks fared. They actually did pretty darn well. The regular adobes bisqued and retained their strength, seems like they could be used instead of red-brick in these stoves, though it's probably too early to really say that.. It was only one firing after all. the rice hull bricks charred through and became very fragile (they were fragile to begin with) though where they were, it might not matter as they wouldn't be getting any impact's etc.. This pic's looking at the char pattern on the rice hull bricks. The brick on the far right there was at the bottom, right in the burn tunnel, so it was getting it from two sides.

, I took it all apart to see how the bricks fared. They actually did pretty darn well. The regular adobes bisqued and retained their strength, seems like they could be used instead of red-brick in these stoves, though it's probably too early to really say that.. It was only one firing after all. the rice hull bricks charred through and became very fragile (they were fragile to begin with) though where they were, it might not matter as they wouldn't be getting any impact's etc.. This pic's looking at the char pattern on the rice hull bricks. The brick on the far right there was at the bottom, right in the burn tunnel, so it was getting it from two sides.

Notice the red color.. It's the clay firing and becoming pottery. It's notable to me how well they hold together.

Here's that rice-hull brick broken open to reveal the inside. It's charred through. It took more to bust than I originally thought it might, still broke easy.

So I thought that (just for fun) I'd try building the standard rocket J tube out of adobe brick.. Just to add a little twist, I've made a few out of rice hulls and clay slip. These extra light, insulative bricks I've placed in the hottest part of the heat riser, the bottom half.

Here's my usual test bed, showing the adobes in the background.

Here are the two types of brick I made. On the left are the rice hull bricks and on the right, standard adobe.

And here is the J tube stuffed with wood and burning, you can't see any smoke.

It burned VERY HOT. It isn't in this image, but at one point there was flame shooting about a foot out of the top.

After the fire burned down and it was mostly cool enough to handle

, I took it all apart to see how the bricks fared. They actually did pretty darn well. The regular adobes bisqued and retained their strength, seems like they could be used instead of red-brick in these stoves, though it's probably too early to really say that.. It was only one firing after all. the rice hull bricks charred through and became very fragile (they were fragile to begin with) though where they were, it might not matter as they wouldn't be getting any impact's etc.. This pic's looking at the char pattern on the rice hull bricks. The brick on the far right there was at the bottom, right in the burn tunnel, so it was getting it from two sides.

, I took it all apart to see how the bricks fared. They actually did pretty darn well. The regular adobes bisqued and retained their strength, seems like they could be used instead of red-brick in these stoves, though it's probably too early to really say that.. It was only one firing after all. the rice hull bricks charred through and became very fragile (they were fragile to begin with) though where they were, it might not matter as they wouldn't be getting any impact's etc.. This pic's looking at the char pattern on the rice hull bricks. The brick on the far right there was at the bottom, right in the burn tunnel, so it was getting it from two sides.

Notice the red color.. It's the clay firing and becoming pottery. It's notable to me how well they hold together.

Here's that rice-hull brick broken open to reveal the inside. It's charred through. It took more to bust than I originally thought it might, still broke easy.