|

|

Post by Donkey on Feb 28, 2015 13:50:52 GMT -8

Depends on a lot of factors.. Seems that last summer the average was between 45 minuets and an hour or so.

I think it should have been an 8 inch stove, rather than a six inch one.

|

|

|

|

Post by Donkey on Mar 10, 2015 9:28:47 GMT -8

I think it's a little under-powered.. When I do this again, it's going to be either an 8 inch J-tube or a 6 inch batch-box.

I'm contemplating turning this one into a batch box. Seems like a clever idea to me, the only real negative that I see is that the firebox will be down at ground level and the user will need to get down on hands and knees to feed it.

|

|

|

|

Post by martinpolley on May 27, 2015 0:34:19 GMT -8

Hi folks, I'm going to tack my question onto this thread because I think it's pretty related  . The oven I'm building is similar to this one, except with firebrick internals and a firebrick hearth. The exterior walls are going to be cob on a stone foundation/plinth. I don't have any experience with cob, so I don't know how thick I need to make the walls. Can you guys give me some pointers? Here's how it looks so far:  Cheers! |

|

|

|

Post by martinpolley on May 27, 2015 1:15:46 GMT -8

Also, do you think my heat riser is tall enough? It's less than "regulation" height, but seems to work OK (I've only burned a couple of bits of paper in it so far). But that's without the channels and the dome that it's going to have to push the hot gases through.

That's not going to be as much resistance as a regular RMH with a flue running through a bench, but still…

|

|

|

|

Post by wiscojames on May 27, 2015 4:30:51 GMT -8

Martin - I have just finished building an earth oven powered by a six inch batch box, inspired by Donkey's work (and others). I think the more you can insulate the whole works, the better. Maybe 2-3 inches of insulative cob (straw, sawdust, perlite, etc.) around the whole thing. After that, a non-insulating finish of an inch or so. The more heat you can get upstream the better. I agree with your assumption that you probably won't need the riser to be full size - mine is a few inches short as well, and seems to be doing fine. Taller might be marginally better, but at the expense of a comfortable operating height.

|

|

|

|

Post by martinpolley on May 27, 2015 4:43:31 GMT -8

wiscojames Sounds cool! Do you have any pictures of it that you can show us?

|

|

|

|

Post by wiscojames on May 27, 2015 9:01:49 GMT -8

When I make another I will probably use firebrick, but the earth batch box has been surprisingly resilient, and the price was right! I previously had a barrel on the thing, which fed the short bench off to the side.  I removed the barrel, built up the base, and made a sort of gabion basket to act as the support for the oven. I would highly recommend this technique as an alternative to other methods, which are typically more labor intensive (and more expensive). There is a 2 foot section of riser in there, on top of the batch box, so the riser is effectively about 36".  I preserved the connection to the bench so that I wouldn't need a chimney in the stove.  This last picture shows the temporary shelter I cobbled together, as well as the arch of the door. Since then I have completed the oven, with the exception of a permanent door and a final coat of plaster. Typical construction: sand dome, thermal layer, insulation layer. I will post more later...  Fired it this past weekend to see how it functions, and to speed up the drying process. I am pleased (or, to stay with the fire theme, 'stoked') with how it performed. First baking session, and more pictures, coming soon. |

|

|

|

Post by martinpolley on May 27, 2015 11:13:15 GMT -8

wiscojames Wow! That's niiiiice! The gabion basket approach looks like a good solution for those of us living in areas without lots of nice, flat, easy to stack stones. The ones in my area look a lot like the ones you've used. Is that the actual surface that you bake on, or is there something else in there? Does the floor get much in the way of heat conducted up from below, or does it rely purely on the heat of the hot gases to make it hot enough? Anyway, that's a really nice job you've done there. Nice one!

|

|

|

|

Post by wiscojames on May 27, 2015 16:39:49 GMT -8

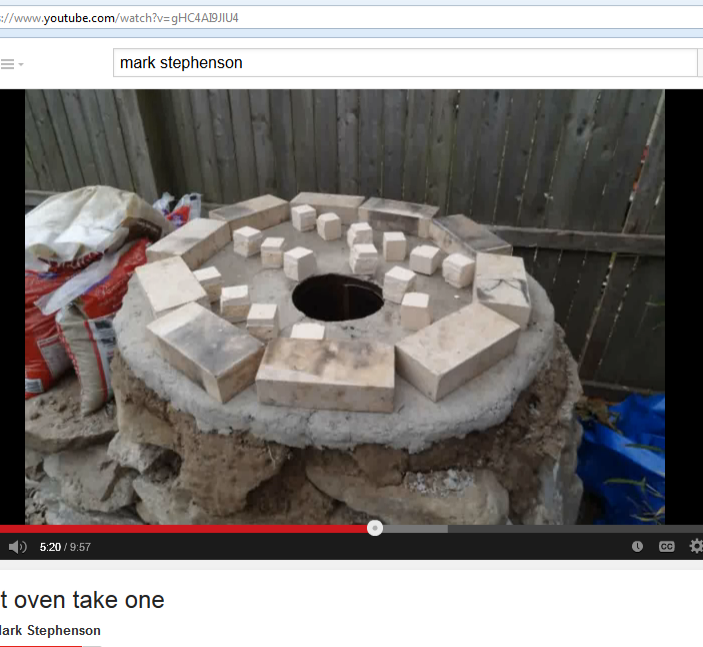

I actually appropriated this fellow's idea: www.youtube.com/watch?v=gHC4AI9JlU4Here is his - I have no photo of mine handy.  So there is a false floor which allows the hot gases to stream up, hit the underside of the floor, circulate around, and find the exhaust. It seems to be working really well. Here's mine, still needing finishing touches and a proper roof:  It seems to be nearly dry, but I suspect it needs a couple more fires. I estimate that I had it somewhere around 500 degrees F. I'll probably get a thermometer tomorrow. |

|

|

|

Post by satamax on May 27, 2015 23:06:22 GMT -8

Wiscojames, where is your chimney exhausting in the oven, top, like many traditional ovens, or near the floor, like a bell?

I hope you have placed the little cubes a bit farther appart, as if there's less than 3cm between them, they would tend to block the flow. Due to friction and boundary layer. Not that important, but a trick to know.

|

|

|

|

Post by martinpolley on May 28, 2015 0:45:07 GMT -8

wiscojames That's pretty cool. Does the dome get hot enough like that though? Do the hot gases make it up into the oven itself, or do they stay under the floor? I'm planning on making mine like the oven that Donkey built, the one that's pictured on the first page of this thread (except with firebricks laid on the mud floor). I'm hoping that the floor will get enough heat from the gases passing through the channels under the floor. Then after that, the gases will enter the dome and flow up across the roof and then out of an opening on the opposite side at floor level. That way, the dome will act like a bell and should heat up pretty well.

|

|

|

|

Post by wiscojames on May 28, 2015 4:38:23 GMT -8

Satamax - the oven exhaust is in the floor, adjacent to the feed of hot gases. I isolated the two, so that the hot gases flow away from the exhaust, then up before going back down, into the bench. I spaced my cubes a little farther apart than in that screenshot above, and I used splits to make sure the gases didn't bypass the dome. It seems to work well, as the dome is getting really hot and the bench isn't. Once I have a nearly airtight door, I will be adjusting a damper on the chimney on the bench.

Martin - I have a total of 9 firebricks in the 'false floor', and like Mark Stephenson, there are ample spaces around the edge for the gases to rise up and heat the dome before finding the exhaust on the floor.

I can't really quantify how efficient it is, but I get the feeling that it is working very well. Now that I have had a couple of long burning fires in it, it's drying out. Soon I will try to quantify it - how many minutes to get to ___ degrees in the oven. Like I said, I think I have already had it up near 500F.

|

|

|

|

Post by martinpolley on May 29, 2015 11:04:28 GMT -8

wiscojames. Sounds like a solid setup. Thanks for sharing. Now you've got me wondering if it might be better to try something similar, but from cob or clay/sand mix. So I'd have "pillars" of cob (like your half-bricks) supporting a mud or cob floor with the firebricks on top of that. Would this work? Would cob work, or is straw a bad idea here?

|

|

|

|

Post by wiscojames on May 29, 2015 12:07:56 GMT -8

Well, the straw will act as an insulative ingredient if there is much of it in there, and I think you want the floor to suck up as much heat as possible. It is a good material for increasing tensile strength, so maybe a little instead of a lot. You could maybe skip the cob floor and just position the bricks on top of the pillars. Without using a uniform product like bricks, though, you might find it challenging to create a flat surface for the oven floor. I will post some results once I have them. I don't have an IR thermometer to get the temperature of the surface, but I do have an oven thermometer now.

|

|

|

|

Post by martinpolley on May 29, 2015 22:03:38 GMT -8

wiscojames I'd worry about the bricks being even enough and not wobbling (even on half brick supports). Has this been an issue for you?

|

|