|

|

Post by juergen on Dec 28, 2009 8:33:49 GMT -8

Dear Peter,

I am new in this forum and it is very interested for me what you are doing in mixing rocket stoves, bells and normal wood heating. At the moment I plan a normal Grundofen for my house in Germany and i stop planing, because I do not know if the Kuznetsov Stove is the better idea! About your firebox, do you know the Broschure serie "Einfälle statt Abfälle" in German, there are a lot of information about much different Fireboxes, the dimensions and also about placing the second air gaps and so on.

Best regards

Juergen

|

|

|

|

Post by endrunner on Dec 28, 2009 9:00:20 GMT -8

Thanks,

Yes the glycerine is liquid. I was thinking of a porcelin tube to drip the liquid. Here is the apartment where I would like to my rocket. Since thermal mass seems to be a positive thing I was thinking of building the stove against this wall.

Dimensions

short triangle piece 59" deep x 60" at top of triangle

Backwall 105" wide x 118" tall

|

|

|

|

Post by Donkey on Dec 28, 2009 11:53:44 GMT -8

endrunner,

Almost any well built rocket stove SHOULD be hot enough at the bottom third of the heat riser to burn glycerin. I'd choose an eight inch system, the kind of heat you're looking for would be more easily attained.

As to images.. Try using the attach function on the reply page. Otherwise you need an image server that will allow external links.

|

|

|

|

Post by peterberg on Dec 29, 2009 3:01:31 GMT -8

juergen, Alas, can't read or speak German, sorry. Although your language and mine are very close. But in aircraft business, where I've been working for 17 years, English is the norm for technical documentation. The Kusznetsov stove isn't a proven concept as a whole, be careful. The air supply and the so-called "dry slots" are subject to debate. The bell principle is proven, though.

|

|

|

|

Post by peterberg on Dec 29, 2009 8:16:51 GMT -8

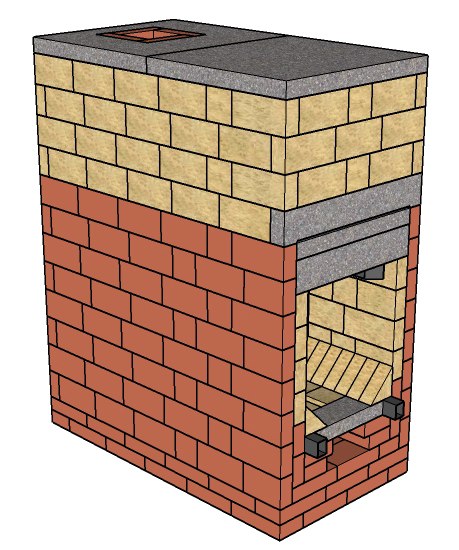

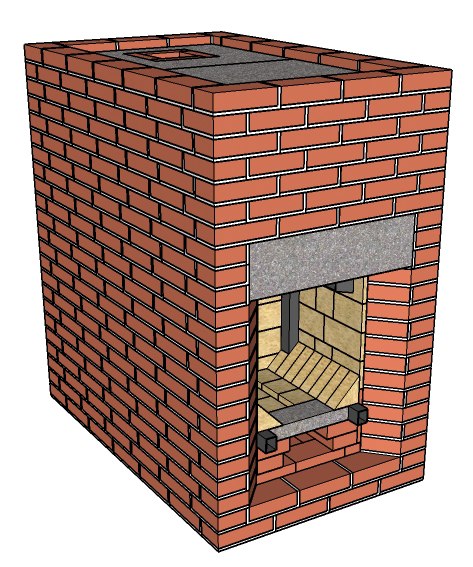

After several times start-over and shuffling with parts the second phase is ready. pberg0.home.xs4all.nl//pictures/PD/RB-PD2.skp This version will be a mix of double- and single skin bells. The first bell is now projected around the core. Around this shell there will be a mantle of brick. Be warned, the shell should be separated from the core by as much as 1/8" to 1/4". Vertical seams by means of aluminum silicate felt or cardboard. The cardboard will disintegrate when the stove will be hot. But because it will be completely enclosed there will be no oxygen enough to burn. Provided around the door opening the aformentioned felt is used. Horizontal seams could be filled with aluminum silicate or woven glass tape. |

|

|

|

Post by juergen on Dec 29, 2009 12:27:25 GMT -8

Hi, peterthanks for your reply. At first and also for all folk in the forum, my english is unfortunately not the best... I am sorry please excuse. I am not sure if there is a small slot in the top of the Kuznetsov´s bell (i can´t find it in the description) to move unburned gases out of the chimney to prevent explosions by opening the door quickly. That is normal and really a must in grundofen fireboxes and drafts. So my question is to you as a experimenter: Do you think that´s a problem in the bell and why is your design so much different to Kuznetsov`s! About rocket stoves I can find not a lot of differences to normal baking fireboxes (long and small and no second air slots in the depth of the hole), all grundofen fireboxes with a vertical draft directly after the firebox have a good roaaar (thermic), produced from the vertical draft. The amazing thing of rocket stoves is for me at first the possiblility to use long branches of wood for burning into the vertical feeder, so there is not a lot of work in cutting and sewing the wood and I can it burn alone with no permanent work (at the moment I use an old german cooking stove and all half hour I have to load it) and second it is an absolut cheap and clever stove with long heating storage using old or common material! After the burn it is necessary to close the wood feeder tight to prevent the cooling of the mass heater through the chimney´s draft! A german mansonry heater company named Kern told me that his Kachelofen can get a efficiency of max. 92 % with normal technology and extra long drafts, it depends on a good draft in the chimney (entrance chimney 180 - 240 °C, top of chimney 60 °C)! I think that are the same physical needs that all stoves have to attend in preventing soot or tar in the chimney and explosions of unburned gases in the firebox! @donkey Hi, why do you think that second air slots are not necessary in rocket stoves? I think in the deeper part of the firebox there is not too much air for combustion and it is a good idea to test those "adjustable" slots to create more heat and fully combustion! In german or austrian fireboxes (for example Rath Biofeuerraum at rath.at) the slots are in a height between 5 - 20 cm. In my opinion 5 to 10 cm above bottom is a good height because it belongs to a normal natural fire outside! thanks Jürgen |

|

|

|

Post by Donkey on Dec 29, 2009 13:40:21 GMT -8

@donkey Hi, why do you think that second air slots are not necessary in rocket stoves? I think in the deeper part of the firebox there is not too much air for combustion and it is a good idea to test those "adjustable" slots to create more heat and fully combustion! In german or austrian fireboxes (for example Rath Biofeuerraum at rath.at) the slots are in a height between 5 - 20 cm. In my opinion 5 to 10 cm above bottom is a good height because it belongs to a normal natural fire outside! thanks Jürgen Hello and welcome. At first I thought that secondary air would be necessary for complete burn. All of my attempts to provide this extra air seemed to fail to improve anything and in fact often made it worse. The aim is to get just enough air into the fire to burn the fuel completely and no more. Less air and the fuel won't completely burn, too much air will cool off the stove or the fire, again reducing efficiency of burn, etc. As far as I can tell, the down-feed J-tube of rocket stoves seems to draw in enough air as it is. I don't know why but it seems not to need any secondary air. The proof is in what little we find in a well burning rocket stove's chimney, time and time again. That said, I'd like to see someone else doing those experiments too. I'm NOT a professional stove builder outside of rocket stoves (and earthen bread ovens), and perhaps I'm missing something critical. |

|

|

|

Post by peterberg on Dec 30, 2009 2:35:15 GMT -8

juergen, The feature you describe is a permanent internal leak, if I'm correct. Not common in most of the stoves outside Germany and Austria. I've been trying to find differences with or without that crevice, different placements and sizes. With some form of a slit, the chimney warms up a little bit quicker and consequently a little bit of efficiency is lost. My design is not very different from Kusznetsov's regarding the bell system. The firebox and second combustion is another matter. The rocket aspect that I do use, which I've been calling the syphon, is very much absent in Igor's design. In contrast with the Kachelofen of mr. Kern: rocket stoves don't depend on a strong chimney draft. To some extent, the same goes for bell systems. My own design will run very well with a chimney entrance temperature of less than 100 °C. Height of the chimney 10 m, cross section 18x18 cm, brickwork, not insulated. No explosions, chimney isn't swept for 3 years. Donkey is right about the second air slots: it won't help at all. I've tried that too, the Testo 327 did show clearly there wasn't any improvement to gain. The same goes for under-fire air, it'll make matters worse. The combustion in a well running J-tube is as complete as it will ever be. With rocket stoves, some lateral thinking is needed. Nothing is what it seems to be, the old rules doesn't apply here.

|

|

|

|

Post by juergen on Dec 30, 2009 6:49:01 GMT -8

@donkey peter (yes it is a permanent slit, size depends on volume of the firebox, the german name is "Gasschlitz") and this slit is a must always at the top of the firebox or and duct (if the first duct goes down!). Is the J rocket and his really special phenomenons explored by physicists? I searched and find nothing about it! Now I have to accept, while its tested (much better than i can do it), that under fire air and the connected slots are not working in rocket stoves. As i am planning building a rocket mass heater Ianto´s style in my home (I have 2 separate chimneys at home) and my wife wants to see the fire burning, I have to wait that peter has done his experiments, because only his arrangement allows that what I need (without the bells) and including the good woodload like a Kachelofen. About Kachelofen, he need the lowest draft from all stoves used in Germany, it starts working with 8 Pascal and 4 m chimneys height. At the moment I believe it is the best to using peters arrangement plus normal ducts (not drafts, sorry!) in the austrian way (long as possible and getting smaller and smaller, per 1°C - 1/257 loss of gas dimension/ is it correct?) and a shortcut to the chimney to get it started. What do you think about the difference in efficiency of bell rocket stove contra grundofen (bestmade!)? Next week i expect to get Iantos Book from the US. ;-))) Peter your chimney isn´t cleaned the last 3 years and he is clean? In Germany it must be cleaned by the chimney sweeper all year preventing fire in the chimney! At home I have a lot of firebricks to make experiments in 2010 ;-)). I wish you both a good and healthy 2010 also a good success in styling rocket stoves! |

|

|

|

Post by peterberg on Dec 31, 2009 2:50:20 GMT -8

juergen, Lately I've been trying to attract some attention of undergraduate students in order of investigating the rocket stove physics. No luck so far. I don't know anything about performance of grundofens. I do know quite a bit how Finnish-style down-drafters perform and of course my own RB-experiments. The highest efficiency a stove can reach isn't a good performance figure, I do believe. Average efficiency do give a much clearer picture. Depending of the time taken, whether or not the tail-out of the burn is included, the load of wood and the moisture content. The same test-run has to be repeated at least three times, after that there's something sensible to say about how the stove is meeting expectations. What my current prototype delivers: Of three comparable test-runs, the highest eff. of all three is 97%, plus or minus 0.3%. Averages are between 80% and 87% over the entire run, starting from cold, including tail-out. The tail-out ends when the O2 is reaching the 20% level again. All done with a Testo 327-1 gas-analizer. Please note, my arrangement is only tested with a bell system behind it. Nothing is known about an Evans' style duct-system/peterberg-firebox combination. At the chapter of chimneys: in the Netherlands a once-a-year cleaning isn't enforced by law. However, in case you've got a chimney fire the insurance won't pay when the chimney isn't swept recently. My chimney do contain a thin layer of black dust on the sides, that's it. Nothing of the flaky or gooey stuff which is very flammable.

|

|

|

|

Post by juergen on Dec 31, 2009 3:46:09 GMT -8

Hi Peter,

about physicists exploring rocket stoves I ask a guy who is well informed in wood gas boiler´s but I know him only via www. We will see if he is interested...

About efficiency, your number of 97 % is an absolute outperformer and your average efficiency is also quite well. Wood gas boilers (I hope it is the right word for it) with needed electric ventilation systems reach not more efficiency (in the end there is loss because of electricity!).

The german law in building grundofens says about efficiency for minimum 78 % otherwise the stove must be closed. In reality the most stoves don´t reach that efficiency because a lot of the stove mason´s built according to it´s feeling not according to the technical descriptions (to huge fireboxes and to short and huge ducts and so on)! That´s why i go searching to another possibilities, expensive and ineffective is not a solution for me.

What I want to tell in my last post is, that I think at the moment there is probably not a great difference between a well done grundofen with efficiency of 92 % and a well done bell Kuznetsov´s style without second air! So the conclusion is that fine tuning of the different systems, like you are doing, brings the best results.

In the beginning, as i saw the rocket mass heater like solunit rocket and so on, I planned a mix between rocket and grundofen firebox including glas door and second air and also the vertical feeder(with possibility of tight closing), but now i know that a second air supply and probably a second fire door disturb the performance of a rocket J stove.

best regards

jürgen

|

|

|

|

Post by peterberg on Dec 31, 2009 6:14:08 GMT -8

Another update of this series is ready. pberg0.home.xs4all.nl//pictures/PD/RB-PD3.skp The mantle is up to the top of the first bell. There's a gap of 1 cm between the mantle and the shell. This can be filled with cardboard, glassfibre or aluminum silicate felt. When cardboard is used, around the door opening it's a must to use a flexible and fireproof medium like the aforementioned felt. The lintel is made of refractory castable, behind it a double layer of felt. Because that's the spot enduring the highest heat stress. The mantle is thought up to be built with a sand-chalk-cement mixture, cement component smaller than usual. It's evident a brick sawing machine (or whatever term you use for that appliance) is really necessary to build such a large stove. |

|

|

|

Post by peterberg on Jan 1, 2010 7:09:32 GMT -8

|

|

|

|

Post by Donkey on Jan 1, 2010 11:25:57 GMT -8

Wow, Peter!

Very good work, Well done.

Thought out down to the details, brick by brick.

Thank you so much for joining us here and detailing your work to this place.

I can't wait to see what you do next.

|

|

|

|

Post by peterberg on Jan 2, 2010 8:54:06 GMT -8

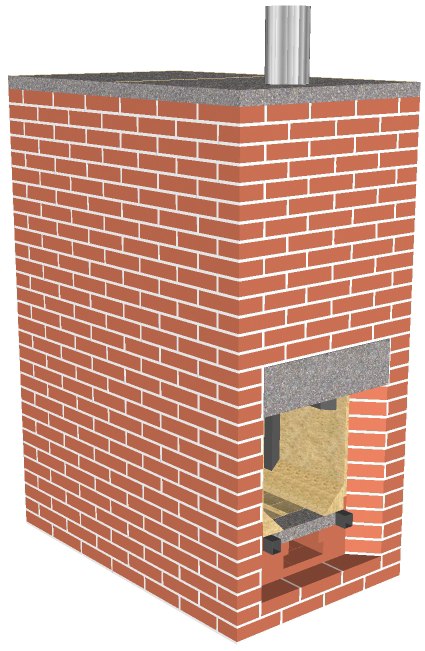

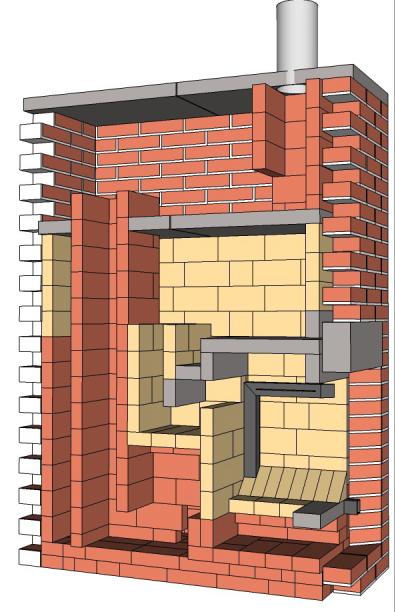

Yet another update: pberg0.home.xs4all.nl//pictures/PD/RB-PD4.skp The second bell is on top now. First bell is double-walled, second bell single. It is possible this way because the second bell is always slower at heating up. Probably the second bell could be larger, but that's depending on the draw of the chimney stack. As it is, this thing would work with a 3' double-walled chimney pipe on top. Last but not least, an open drawing to view the channels etc. without dismantling the drawing itself.  The door, one of the most important parts of the stove, is the last nut to crack. It could take a while before that is finished. |

|