|

|

Post by Jura on Jul 25, 2017 3:00:57 GMT -8

I was asked to start an 18 cm RMH project. (urgently as investors are about to move in but they were told they wouldn't be connected to a gas network which results in their floor heating being useless and they may end up spending winter in an unheated house)Investors insist on having a bell and a ~3 m long brick bench. I was reluctant as from previous forum lecture I got a feeling peterberg is rather against connecting duct bench to bell. (i n fact my gut feeling tells me I shall also by an opponent as I'm familiar with the free gas movement theory, too)

but there exists benches of length and amount of U-turns which should not theoretically work Unfortunately the chimney is situated in a corner thus excluding (correct me if I'm wrong,please) a blind bench and requires a channelled one. As picture is worth of 1000 words I attach photos and plan with a kind request for tips and critique. I spent quite a lot of time on browsing the forum in a search for info: To summarize what I found: - The entry from a bell to a bench channel shall have significantly bigger CSA than the system (how much?) - 5 feet(~1,5 m) channel length deduction for every single 90 deg turn. - channels and the entry to the chimney shall be wider than higher (if the duct has rectangular shape). The belows punctuations are for the info which did not find out  - - - What I'm worried is whether the system will create enough draft.

Are you able to estimate it basing on the belows data?The ISA of the bell itself is already 7,32 m 2 :-( (excluding columns supporting the ceiling) (I can not decrease the bell size as investors want the core to be 40 cm elevated. Moreover the chimney inlet for the short way bypass is located @ the height of 1,99 m so I need to have inside the bell) - The chimney is a ceramic modern system. - The building is relatively well insulated (114 kWh/m 2/year) - I'll add a short way bypass) for start up smokeless ignition - the bench entry from the bell will unfortunately be placed in a corner   UPDATE 05.12.2017 I'd like to add some photos:                              |

|

|

|

Post by satamax on Jul 25, 2017 5:41:26 GMT -8

I think you could do a blind bench no prob.

|

|

|

|

Post by Jura on Jul 25, 2017 8:08:00 GMT -8

I think you could do a blind bench no prob. Thanks. How do U think what is the chance the flue gases will not go directly to the chimney? What's your opinion on the projected duct bench ? |

|

|

|

Post by satamax on Jul 25, 2017 8:58:13 GMT -8

Well, your bench looks all right. I would do a bench bypass, into the chimney. Just in case it doesn't want to start.

Otherwise a Bell bench should work too. Let say chimney open at about 10cm from ground, and inside top of the bell is at 40, you get 30cm working height. I would make the big and bench bells a single Bell. The entrance of the bench bell, would be at 40cm.

|

|

|

|

Post by satamax on Jul 25, 2017 8:59:18 GMT -8

And use the existing chimney as a plunger tube.

|

|

|

|

Post by Jura on Jul 26, 2017 0:51:23 GMT -8

Well, your bench looks all right. I would do a bench bypass, into the chimney. Just in case it doesn't want to start. Wouldn't the bypass I mentioned in my starting post(placed @ ~2 meters) be enough ? Otherwise a Bell bench should work too. Let say chimney open at about 10 cm from ground, and inside top of the bell is at 40, you get 30cm working height. I would make the big and bench bells a single Bell. The entrance of the bench bell, would be at 40cm. I'm sorry but try as I might I couldn't imagine what you are proposing. Would you "waste" more of your precious time to explain it as for a dummy. And use the existing chimney as a plunger tube. My Lord! ;-) It seems my mind is out of order today ;-). I even consulted google graphics for the phrase "plunger tube" and...I'm even more confused.  BTW. i'm also curious about the plaster on your walls. how is it doing? We have a pretty rainy summer in here isn't it soaking through from splashing water? |

|

|

|

Post by satamax on Jul 26, 2017 1:34:48 GMT -8

Jura, i'm a tosser. The plaster on the strawbales isn't done ! Plunger tube. A tube entering the Bell from the top. And nearly reaching the bottom of the Bell. With the dame kind of gap as the heat riser gap. (Or less) It was a way for me to say that the actual chimney should be in the Bell. And if you have a bypass at 2m high, it should be fine. Tho, it won't heat the Bell much. One rather close to what you want to do. mha-net.org/docs/v8n2/wildac15f.htmA drawing is Worth a thousand words. |

|

|

|

Post by Jura on Jul 26, 2017 4:48:48 GMT -8

Jura, i'm a tosser. The plaster on the strawbales isn't done ! Hold on! That's not the way I'd call it  I'd rather name such behaviour as acting by not acting (kinda buddhist manner). but I can see now that your signature as procrastinator is not just mere joke  . I lean toward opinion that it is the procrastinators and twice-thinkers who push our tech-based civilisation forward. Plunger tube. A tube entering the Bell from the top. And nearly reaching the bottom of the Bell. With the dame kind of gap as the heat riser gap. (Or less) By the same gap you mean the distance from the heat riser exit to the ceiling? It was a way for me to say that the actual chimney should be in the Bell. Thanks for clarification. Now I get what you meant. But @ the moment I can not recall why I gave up such idea.I'll get back to reconsider it. And if you have a bypass at 2m high, it should be fine. Tho, it won't heat the Bell much. The bypass will be adjustable and open only while starting a cold system. I hoped it was clear. I had perused over this Peter's build description for quite a while. Especially over the part which describes how to make the gase not to flow directly to the chimney. The description comes from batchrocket.eu/applications"The placement of the exhaust opening to the chimney stack is very important in this design, as in any bell design. As this design has benches attached to it (absent from the previous examples shown) thought needs to be given to how we get the hot gases into the benches and not 'short circuit to the exit flue' beforehand. The drawing below shows how it was achieved. A fireproof baffle board (in this case calcium silicate) is placed off the rear wall of the main bell and capped off at the top, see 3D drawing how this is done. Not seen in the picture below is the exit flue, 'hidden' behind the baffle plate. The circumference of this baffle board multiplied by the distance between it and the rear wall of the bell should be much larger than the cross sectional area of the flue.  But they had the chimney at the back wall of the stove and benches at its sides. Therefore having a chance to build some barrier restricting the flow of gases to the chimney directly. With my design I have no clue how to achieve it and make gases flow to the end of the blind bench :-( instead of flowing directly to the chimney which is placed at the very beginning of the bench (ie. in the place where the clean out doors are now -> photo) Is my explanation understandable? |

|

|

|

Post by satamax on Jul 26, 2017 6:35:16 GMT -8

Jura, i would say minimum gap. for a plunger tube. May be 2 to 3 times CSA.

As the gap you would use with a barrel and J tube. Not a huge gap like in a batch rocket with bell. With a big chimney like this, , low and wide gap opening, towards the bench. And use a wall at 45° from the chimney's corner to somewhere towards the wall, in the bench, which would keep the proper CSA. As a baffle.

If you use an opening where the actual cleanout is for the moment. If the internal width of the chimney is 20cm, your opening height should be about 13cm from floor. And less if the chimney inside is larger. at 25 width, you get 11cm. 30, 8.5cm. And so on. Careful if you get any smaller than 6 cm height, the friction due to the boundary layer comes into play seriously.

|

|

|

|

Post by Jura on Jul 26, 2017 10:32:22 GMT -8

Jura, i would say minimum gap. for a plunger tube. May be 2 to 3 times CSA. If you use an opening where the actual cleanout is for the moment. If the internal width of the chimney is 20cm, your opening height should be about 13cm from floor. And less if the chimney inside is larger. at 25 width, you get 11cm. 30, 8.5cm. And so on. Careful if you get any smaller than 6 cm height, the friction due to the boundary layer comes into play seriously. I'm so grateful to you for directing my issue but... shame on me - can not visualise your proposal. Is there any slightest chance for a brief sketch,please? |

|

|

|

Post by peterberg on Jul 26, 2017 11:17:04 GMT -8

The person who brought up the idea of a blind bench as part of the main bell was me. Klemen from Slovenia built the first one as far as I am aware of. In the mean time I have aquired a pretty good picture of the stream patterns involved.

First how it is supposed to work: the bench should be completely open to the main bell so the hot gases, coming down in the bell will stream into the bench next, mainly in the top half. The colder gases, being at the bottom of the bench are displaced by the warmer ones and start to stream back and to the exhaust opening. The bell/bench combination doesn't need to be symmetric, since the feeding of the bench is by gravity, hotter gases are expanded and therefore much lighter than colder gases. With a well placed exhaust opening, it doesn't matter where that opening is in the bench, even close to the inlet side of the bench.

Wherever the exhaust opening is, it should be as low as possible and much wider than the csa of the chimney. The reason to have a wider opening is this: the gases are coming mainly from above and less over the floor so that latter one is ignored in the calculation. The effective opening is dictated by the "stream profile" formed by the top ridge and the sides of the opening. Take the length of this ridges and multiply that by the distance directly in front of that opening. The resulting figure should be at least as large as the chimney's csa, preferably much more.

Now how to go about with the situation you need to deal with.

In your case, I would integrate the chimney in the bell itself. At floor level, I would make two wide and low openings, in the sides that are exposed in the bell. This should be wide enough not to pose a restriction whatsoever. A bypass to the chimney would be placed best about halfway the height of the bell, thereby avoiding to be situated in the hottest environment.

A good way to imagine how the gases will stream and in which direction: turn the whole model upside down in your mind or on your computer screen and imagine it is gradually filled with water. It will allow you to see where it fills up first and where last. Obviously, it should reach the exhaust opening last.

By the way: the drawing of the MHA workshop shows a symmetric setup, but in reality this wasn't the case. One bench was placed a bit more to the back and as a result it warmed up slower. In order to close your bench with bricks, you could build a row of small free standing pillars for support. This way, the working of the intended bell isn't hampered.

More specific questions? Fire away! (pun intended)

|

|

|

|

Post by Jura on Jul 26, 2017 15:44:49 GMT -8

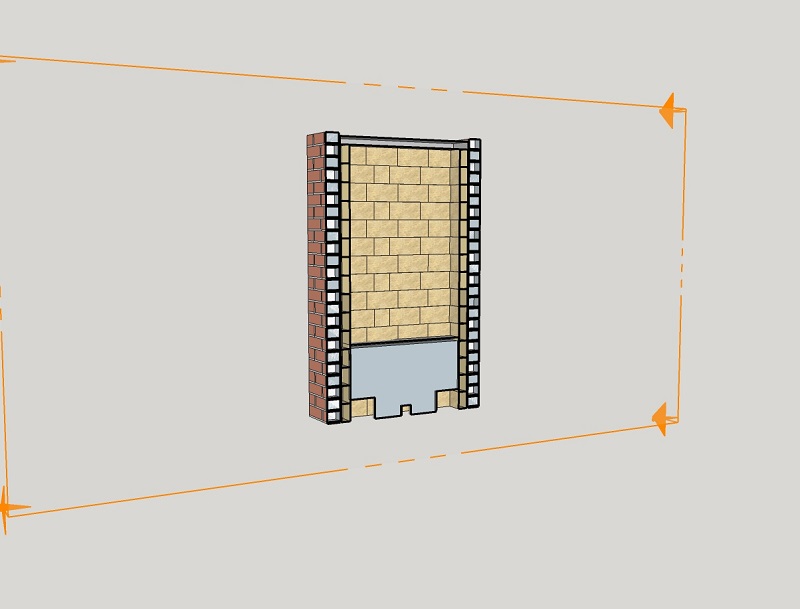

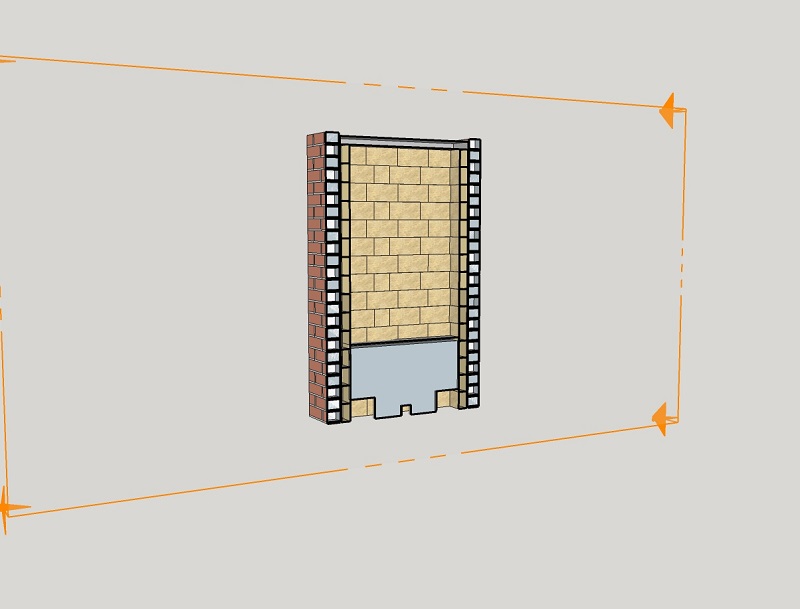

... With a well placed exhaust opening, it doesn't matter where that opening is in the bench, even close to the inlet side of the bench. Firstably! Thanks so much for your answer ! I do like your posts as not only they contain "hows" but "whys" as well. But as to your above statement I'd kindly ask for some more indications, examples, tips, hints so as to understand it. Wherever the exhaust opening is, it should be as low as possible and much wider than the csa of the chimney. I'm constrained here as the chimney duct CSA = 314cm 2 (the chimney diameter is 20 cm) and it is so called the system chimney. (sized 36 cm x 50 cm.) The rest of the chimney space contains 2 vent ducts. So the max width of the opening I can have is ~20 cm. How about their height in such case? I'm also anxious as to cutting off such openings in the base of the chimney and wandering if it would not decrease its structural strength. Would you be able to estimate it? ( familiar with the pressure, tensions, Yung modules, etc? Now how to go about with the situation you need to deal with. In your case, I would integrate the chimney in the bell itself. At floor level, I would make two wide and low openings, in the sides that are exposed in the bell. This should be wide enough not to pose a restriction whatsoever. Is the below image showing what you meant  A bypass to the chimney would be placed best about halfway the height of the bell, thereby avoiding to be situated in the hottest environment. Hugh! Now you reminded me the reason which I excluded the chimney from the bell for. I wanted to instal the start up ignition bypass (sliding one, castiron) and it is difficult to get one with a handle long enough to reach the outside of the bell. So one needs to go makeshift. Such solution increases complexity and the more complicate system we deal with the higher probability a of a fault occurrence  More specific questions? Fire away! (pun intended) YES SIR! ;-) With pleasure But so as not to get lost in too many of them at once I'll hold my horses (carrying a canon) and load it with questions for next salvo. (I realize my pun went off a bit of the direction indicated by yours ) |

|

|

|

Post by peterberg on Jul 27, 2017 8:04:58 GMT -8

But as to your above statement I'd kindly ask for some more indications, examples, tips, hints so as to understand it. Your own drawing in the post above is answering that already. The exhaust opening isn't even in the bench but in the bell instead. Both openings are low in the chimney stack, well below the top of the bench. I'm constrained here as the chimney duct CSA = 314cm 2 (the chimney diameter is 20 cm) and it is so called the system chimney. (sized 36 cm x 50 cm.) The rest of the chimney space contains 2 vent ducts. So the max width of the opening I can have is ~20 cm. How about their height in such case? Let's see where this leads us. I commented the space in front of the respective openings is a factor too. The one facing the bench has no blockage in front of it, so the whole of the opening is utilised, the gases are able to stream over the floor itself. More or less the same goes for the opening facing the bell, provided the support of the combustion core isn't too close by. Two openings of width x height= 20 x 10 cm would provide plenty of room in this case so there wouldn't be any restriction. As for the structural strength of the chimney: even a simple masonry chimney could be constructed like that. And I know personally of a stack made of earthenware modules which is cut out like this at floor level. This is functioning for about 5 years now, no complaints as far as I am aware of. Your drawing is reflecting what I meant. But I would put some heat resistant cladding on the stack which is exposed in the bell. This could be split firebrick (the kind that is only 30 mm thick) or superwool blanket, at least the part that is above the riser's end. In my mind, the only thing that need to be done is lengthening the rod of the bypass valve. Every person who's able to handle a welding apparatus could achieve that. Nothing to be anxious about, I'd say. But it's your choice, I am here to scrutinize your plans if that is helping you. Your drawing is reflecting most of the principals already, so I'd say you are on the right track. |

|

|

|

Post by Jura on Jul 28, 2017 3:39:35 GMT -8

More or less the same goes for the opening facing the bell, provided the support of the combustion core isn't too close by. well..In fact it is pretty close (~10 cm) as I must use the sidewinder system to fit into the area available. How prohibiting would it be for applying your bell-bench solution? The only thing I could do is to build the core support of a refractory plate based on some pillars (with as aerodynamic shape as I can get using hand grinder) which would allow for some gas flow under the core support. But I would put some heat resistant cladding on the stack which is exposed in the bell. This could be split firebrick (the kind that is only 30 mm thick) or superwool blanket, at least the part that is above the riser's end. Definitely. When I first considered the chimney in the bell I wondered whether it would be prudent to spray the superwool surface with a clay slip to get a thin layer protecting it from fraying. Any opinions on that ? Another restriction as to the projected build: The ISA of the bell itself was 7,2 m 2 excluding the bench. Now with some 1m 2 of bell surface more I might be getting too much over the advised (as you called it " conservative side") number of ISA. Will the 18cm system manage "somehow" to maintain the exhaust fumes temp at desired level? Or maybe I shall rather turn for the 20cm system ?

|

|

|

|

Post by peterberg on Jul 28, 2017 5:05:28 GMT -8

More or less the same goes for the opening facing the bell, provided the support of the combustion core isn't too close by. well..In fact it is pretty close (~10 cm) as I must use the sidewinder system to fit into the area available. How prohibiting would it be for applying your bell-bench solution? There are two of these openings, remember? Together the size is 400 cm², not quite as much as 1.5 times the chimney's csa but still very adequate. The only thing I could do is to build the core support of a refractory plate based on some pillars (with as aerodynamic shape as I can get using hand grinder) which would allow for some gas flow under the core support. Having slow air flow under the combustion core is a good thing, it promotes heat transfer to the mass. No need to shape the pillars aerodynamically, since gas velocity is low there. When I first considered the chimney in the bell I wondered whether it would be prudent to spray the superwool surface with a clay slip to get a thin layer protecting it from fraying. Any opinions on that ? Stop the superwool from fraying is not bad in itself. However, even during the first burn there will be some soot sttling on it. Alternative: spraying waterglass. Another restriction as to the projected build: The ISA of the bell itself was 7,2 m 2 excluding the bench. Now with some 1m 2 of bell surface more I might be getting too much over the advised (as you called it " conservative side") number of ISA. Will the 18cm system manage "somehow" to maintain the exhaust fumes temp at desired level? The recommended size for such an 18 cm system would be 7.6 m². That means all together, bench and bell since the bench is part of the main bell in this respect. So I am curious whether the combined numbers are far over the recommended value? When the combined numbers add up to 8.2 m² I would say it can be done cause you also employ a bypass. Might be that the bypass need to be open just a crack at all times to keep velocity in the port high enough. On the other hand, the chimney is a modern one and straight up isn't it? This helps a lot, in my experience. Or maybe I shall rather turn for the 20cm system ? A 20 cm system should be able to facilitate 9.4 m² of ISA, combined with a bypass you could easily go a square meter more. But maybe you could ran into trouble concerning the height of the riser. I understand your projected riser is 10 times base figure now, when you revert to 8 times the bell would be smaller or you could fit in the 20 cm system with an 8 times base riser in the existing bell height. All this are the designer's decisions, what can be done versus (or helped with) the wishes of the client.  |

|