Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jun 27, 2017 1:17:00 GMT -8

Hi everyone, I'd like to show you a batch I've made in a workshop with others in April, 2017 in France. The core is in refractory bricks, the rest in adobes we did during the workshop. The heater has been dried for two months and then fired everyday with a wood load gradually ranging from 1 kg to 10 kg in two weeks to fire the bricks. Then we did an inauguration with a full 21kg load. The client is a professionnal pizzaiolo and when we fired the heater the oven temperature went over 500°C. The large bricks which make the bottom of the oven went to 250°C max. The plancha temp goes around 100 to 150 °C, which is pretty nice for direct cooking on the plancha. There is also a coil for hot water directly under the plancha and I've been thinking quite much on a good solution.. but a proper realisation (ie. thermosyphoning for the main loop and the discharge loop) nearly doubles the cost of the heater ! The ISA of the bells of the heater is 7 m2. The ISA of the chimney is 4,5 m2 : I added half of this surface to the total ISA (peter's idea) because the chimney is not a bell. Total ISA of the heater without the hot water coils is thus 9,3 m2. For a double bell with a batch of this power it should be 10,6 m2. The exit temperatures during the full load firing where very coherent with this so I'll stick with this rule with updraft parts in the heater. The sketchup drawing is here : - uzume-asso.org/assets/plans_sketchup/Batch230_pourcieux_V5/batch230_pourcieux_V5_sketchup8.skp- uzume-asso.org/assets/plans_sketchup/Batch230_pourcieux_V5/batch230_pourcieux_V5.skpTwo videos of the heater : Some images :    Regards, |

|

|

|

Post by Jura on Jun 27, 2017 3:09:44 GMT -8

Respect!

I can see the you tube clips but not the photos.

I'm wondering what was the temperature of the "pizza door" glass in the half of of batch burn.

Did you apply any mesh before applying the clay plaster (4:1 or stroner mixture)?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jun 27, 2017 3:26:01 GMT -8

Hi Jura, thanks !

The temperature of the black oven door was around 250°C during the height of the burn.

No mesh, I use donkey manure (10% in volume) in the final layer. Here the final layer is not applied yet -- I let the body layer crack and everything move. The final layer will only be applied when the cooking of the bricks is done.

Regards,

|

|

|

|

Post by ronyon on Jun 30, 2017 18:05:18 GMT -8

Nice work!

In the first video, flames were visible through the open side(?) of the oven door.

In the second video, none were visible.

What made that difference?

Is the side of the oven simply open to the flame?

|

|

|

|

Post by satamax on Jul 1, 2017 4:11:52 GMT -8

Viry viry noice!

Seems very familliar tho.

|

|

|

|

Post by pyrophile on Jul 1, 2017 10:33:29 GMT -8

Salut! Hi!

Chouette boulot! Great job!

Aren't the stove's walls rather hot with such a big system?

If the plancha is homemade, how thick is it?

(edited)

Benoit

|

|

|

|

Post by pyrophile on Jul 11, 2017 14:09:07 GMT -8

Yasin, where did you get your isolated cylinders for your heat riser, please? Is it expensive?

Thanks!

|

|

|

|

Post by Jura on Jul 12, 2017 4:00:15 GMT -8

One more question: I had a lok @ the file and measured your heat riser. It is ~1,2 m high. It seems to be more suitable for the 180 cm system (1286cm) than the beast you built. Have you done it on purpose ? or faced some constraints? |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jul 12, 2017 11:12:31 GMT -8

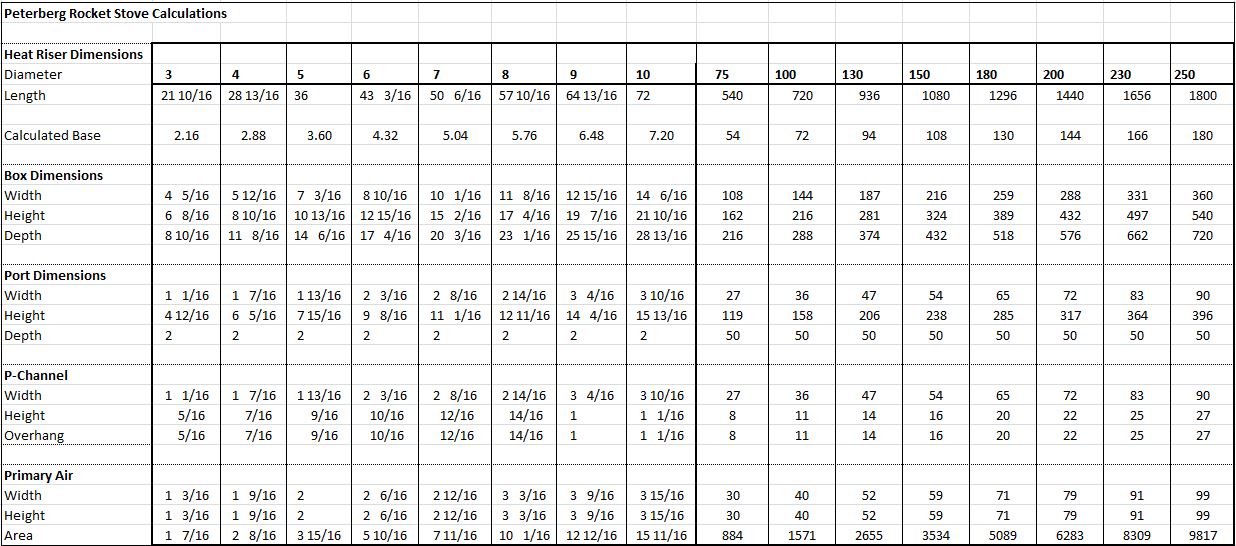

Hi everyone ! Thanks ! - ronyon, the flames were there in the second video because of a mighty reloading ! On the first one it was only a small fire. Black oven directly in the bell. - benoit, I sent you a PM. The plancha is home-made, 8 mm thick. - jura, the height of the riser is between 8 and 10 times the base value. For a 230 it's 100 mm under the minimal size. The heaters are too high otherwise. see the spreadsheet here : uzume-asso.org/batchrocket_construction.htmlregards, |

|

|

|

Post by Jura on Jul 12, 2017 12:14:56 GMT -8

hmmm... I always used dimensions from peterberg spreadsheet @ batchrocket.eu  As you can see the height of the heat riser for the 230 system in there is to be 165 cm. I wonder if there is any statement about origin of their HR sizing on the website of uzume-asso provided to suport the different dimensions. I aslo wonder if there was any discussion here about the ramp at the bottom of heat riser. |

|

|

|

Post by peterberg on Jul 12, 2017 13:06:31 GMT -8

Jura, at the batchrocket site, just below the table of dimensions is a summary of the different measurements. The 8 to 10 times base value is mentioned there. Everybody is free to use other dimensions at their own accord, of course.

As far as I know, there hasn't been a discussion about the backsweep in the heat riser.

I tested it with that ramp and without, and the results were markedly better with the ramp included. It helps to direct the gases upwards, provided it isn't much higher and deeper than half of the riser's diameter. What it does is simply eliminating a corner which would otherwise cause a lot of unwanted and counterproductive chaotic turbulence.

That is to say, that's my interpretation of the numbers back in 2012.

|

|

|

|

Post by Jura on Jul 13, 2017 12:23:59 GMT -8

Jura, at the batchrocket site, just below the table of dimensions is a summary of the different measurements. The 8 to 10 times base value is mentioned there. Everybody is free to use other dimensions at their own accord, of course. Thank you Peter for the prompt reply. Correct me, please if I did not get your words right. I thought the sizes you shared in the table were the optimum one, right? (with regard to efficiency I mean) 8-10 times base vallue. as I get it the closer to 10 vale the more complete burn occurs, right? While conducting your tests you have probably played with different HR heights. Have you happen to have this data still and would you be wiling to share it ? I mean the efficiency=f(HR height). I'd like to explain why i'm pushing the topic so much. If the shorter HR causes it to fall below 69 % then there is no longer sense to apply rocket stove construction as this level (AFAIK) we may obtain by well projected masonry firebox. As far as I know, there hasn't been a discussion about the backsweep in the heat riser. I tested it with that ramp and without, and the results were markedly better with the ramp included. A detail I missed. But hopefully my palm will will fit into HR via the port and I'll manage to add it. |

|

|

|

Post by peterberg on Jul 15, 2017 7:56:40 GMT -8

I thought the sizes you shared in the table were the optimum one, right? (with regard to efficiency I mean) 8-10 times base vallue. as I get it the closer to 10 vale the more complete burn occurs, right? Not exactly about efficiency, closer to the value of 10 there's less chance of overfuelling. Lower than 8 there's a greater probability but absolutely not guaranteed. This behaviour has also dependencies on how the rest of the heater is built, how good the door is, the quality of the chimney stack and last but not least the level of expirience of the operator. While conducting your tests you have probably played with different HR heights. Have you happen to have this data still and would you be wiling to share it ? I mean the efficiency=f(HR height). It's 5 years ago and I moved house in the mean time. All my notes were scribbled on scraps of paper, no lists or anything like that, sorry. I'd like to explain why i'm pushing the topic so much. If the shorter HR causes it to fall below 69 % then there is no longer sense to apply rocket stove construction as this level (AFAIK) we may obtain by well projected masonry firebox. I do get the strong impression you are focussing on the efficiency subject far too much. And it depends on what you mean: combustion efficiency, heat extraction efficiency or overall efficiency. The Testo gives a number of overall efficiency of lower heating value, which is about a 12% higher number as higher heating value. That last method is minus chimney losses, dry gas losses, CO losses and so forth, the more honest way to measure. But as long as I am using the same instrument I will be able to compare what the best layout is. Apples to apples so to speak. Overall efficiency is combustion efficiency multiplied by heat extraction efficiency. So the batch box is able to peak at 99% cumbustion now and then, but on average that would be about 95%. A very well designed bell system could retrieve, say, 85% of the produced heat. So the overall efficiency would be around the 80% mark, 95 multiplied by 85%, higher heating value. Since the Testo is showing lower heating value that would result in a 92% figure. Exactly what my red bell has been achieving last winter, my best performing heater up to this day. Even a combination of a batch box rocket built by the numbers and a sloppy bell would be able to reach more than 69% overall efficiency, whatever method you choose to measure it so don't worry. As long as the exhaust temp isn't as high as 350º C, of course. |

|

|

|

Post by Orange on Oct 26, 2017 3:50:25 GMT -8

Hi everyone ! Thanks ! - ronyon, the flames were there in the second video because of a mighty reloading ! On the first one it was only a small fire. Black oven directly in the bell. - benoit, I sent you a PM. The plancha is home-made, 8 mm thick. - jura, the height of the riser is between 8 and 10 times the base value. For a 230 it's 100 mm under the minimal size. The heaters are too high otherwise. see the spreadsheet here : uzume-asso.org/batchrocket_construction.htmlregards, I've noticed the port depth you have is 110mm, almost double. But I like the design  |

|