|

|

Post by ronyon on Sept 29, 2013 19:46:28 GMT -8

How does this sound?

Get a scrapped double oven, build your "j" in the bottom oven up through a hole into the top oven, add firebricks to the top, a diffuser plate above the incoming exhaust, and vent the oven via a hole at the lowest point on the oven and as far away from the heat riser as possible.

The ovens are already insulated, but that insulation could be removed /and or added to.

The idea behind this design is to avoid the difficulty of building a fire resistant container, and simply "occupy" an existing one hermit crab style.

|

|

timmy

New Member

Posts: 4

|

Post by timmy on Oct 4, 2013 2:19:05 GMT -8

I did see someone convert an existing wall oven into a rocket oven.... not sure where it was now but I think it was one of those hippy sustainability websites. From memory they had a water heater on top to use the leftover heat.

|

|

|

|

Post by satamax on Oct 4, 2013 17:59:15 GMT -8

I would think you could do it in the french ranges (cuisiniere a bois) I don't know how the foreign ones are aranged. I would put the J tube burn tunel through the ash box door at the bottom, heat riser going up into the old firebox. Leaving the feed tube outside Here's a pic of a modern one  Top door on the left is the firebox, and bottom one being the ash box door. Old french ones look prety much like this one.  Well, off to work guys. Over here at least, there's plenty about on leboncoin.fr |

|

|

|

Post by woodrascal on Oct 9, 2013 12:01:02 GMT -8

Hi everyone - first post on the forum so please be gentle...

I've been experimenting with rocket heat risers in our woodfired ESSE W23 cast iron range cooker for the last 6 months or so.

I'm very busy with work and Family matters at the moment but when I get some time(!) I'll post a detailed account of how things are progressing. In a nutshell, things are looking very promising indeed.

All the best,

John.

|

|

|

|

Post by satamax on Oct 9, 2013 22:25:25 GMT -8

Hi John!

We need pics.

|

|

|

|

Post by woodrascal on Oct 10, 2013 10:21:20 GMT -8

Hi Satamax - I'll get something sorted soon... It's all a bit 'work in progress' so please bear with me!

|

|

|

|

Post by colinsaengdara on Oct 18, 2013 6:48:15 GMT -8

Max, that modern one is about the most beautiful stove I've ever seen! Looks like it weighs about 4 tons though!

-Colin

|

|

|

|

Post by satamax on Oct 18, 2013 13:07:16 GMT -8

Max, that modern one is about the most beautiful stove I've ever seen! Looks like it weighs about 4 tons though! -Colin 400 or 500 kils at most i'd say! |

|

|

|

Post by woodrascal on Nov 12, 2013 13:33:36 GMT -8

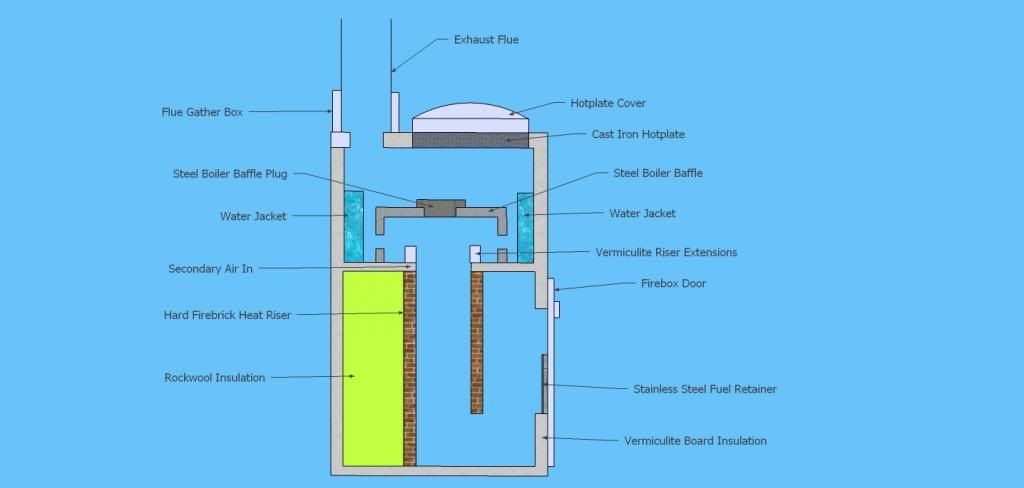

Hi Max and other forum members! As promised a bit more information about my Rocket conversion of a range style cooker. The cooker in question is the ESSE W23 - here's how a new one from the factory looks  It's a wood fired appliance with a fitted 23,000btu boiler fitted. We went with this cooker because it has an insulated firebox that is seperated from the boiler - it burns hotter and cleaner without the boiler cooling combustion. It works very well but having experimented with rockets in various guises, I have become aware of the quite high fuel consumption of the unit compared to a rocket. Basically I've fitted a hard firebrick heat riser INSIDE the existing vermiculite lined firebox. The downside to this arrangement is the restricted space available for the feed tube/burn tunnel (which is effectively a firebrick thickness long - around 35mm) This limits the amount of fuel that can be added and makes construction quite complicated.... The upside is that by using the existing firebox everything is very well insulated and I can control the air feed (and prevent blow back) by using the firebox door as a damper. Another bonus is that on the original cooker design a pre heated secondary air feed is introduced where my new heat riser exits the firebox. Here's a rough sketch up section to show what's happening - Esse Rocket Modification 111113.skp (241.46 KB)  Hopefully(!) these photos will show what it all looks like in reality - it's all still work in progress so please ignore the rough edges... This is the top of the cooker where the boiler is located with the hotplates removed showing the top of the heat riser and the secondary air holes. ![]() I've removed the steel boiler baffle deflector so we can see down the heat riser. You can see the flaking of the boiler jacket on the left. We've had the unit for over 6 years and the mild steel boilers probably on its way out - doubtless the rocket will speed up its demise!  This one shows what is effectively the feed tube and burn tunnel at the base of the heat riser ![]() . The firebricks are ex-storage heater bricks that I had in stock. I've tried various hard fire clay and vermiculite board versions and they've quickly failed. The storage heater bricks do seem to last longer (although they do degrade in the intense heat) and hold their heat for several hours once up to temp. The right hand support is a piece of angled soapstone that adds a bit of a vortex to proceedings. The slide control at the base of the firebox door (covered in spilled ash...) feeds the primary air to the firebox when the door is fully closed.  And this photo shows the unit under fire ![]() . The stainless steel plate slots in to provide the 'front' of the J tube feed. It sometimes glows red hot when the unit is roaring away and if you touch a stick on it, it self ignites. You can in most cases leave the firebox door open without any blow back problems, but I usually keep it closed or on half latch to hopefully help the efficiency.  The modified unit works really well. The oven gets up to temp faster and uses much less wood to cook and heat water. There is virtually no smoke exhausting from the chimney - even on lightup. On the minus side it does need fuelling quite frequently and the restricted space of the feed tube inside the Esse's firebox limits the size of the wood you can use. I'm wondering if I could use an angled heat riser? This would give me more fuel space. |

|

|

|

Post by davidw87 on Nov 14, 2013 4:34:31 GMT -8

This is a nice piece of re-engineering and adds more to the wild (likely imparcticle/impossible) thoughts going round my head.

I've only come across Rocket Stoves/Ovens recently as I will be moving into a new place with my fiancee in hte new year and would love to have an outdoor cooker, but one that could be moved if needed. I know a range oven isn't exactly light but would be alot more practicle than dismantling a brick one and reassembling once moved, plus our garden isn't too big.

From what I understand (and please correct me if I'm wrong) Rockets have the advantages of less fuel being used (though needs refuelling more often) and reach cooking temperatures quicker; is this still the case for your modified unit or do you find it takes similar time but you less wood?

Thanks for your time.

Cheers,

David

|

|

|

|

Post by woodrascal on Nov 14, 2013 5:59:31 GMT -8

Hi David

The rocket modified cooker does reach cooking temperatures faster. From a cold start the main oven reaches around 190 degrees C in about 35 to 45 minutes - previously this could take between 1 hour and 1 1/2 hours. The hotplates are appreciably quicker to heat up and are much hotter overall. As you say the wood consumption is much less - difficult to quantify at present, but I'm guessing it's probably using around 50% less fuel for the same performance.

One slight disappointment is that the hot water boiler seems to perform in a similar fashion to its 'pre-rocketed' state. I was hoping it would provide more central heating capacity, although the DHW side does works very well. I'm thinking that the exhaust gasses from the rocket are moving past the boiler jacket at too great a speed to allow the efficient transfer of more heat to the boiler. I've a plan to modify the existing steel boiler baffle to improve this. Ideally I really want to fit a new Stainless Bell type boiler (see another thread) with an adjustable baffle diverter to try to capture some more of this heat.

|

|

|

|

Post by Donkey on Nov 15, 2013 7:47:05 GMT -8

You've mentioned secondary air coming in to the top of the heat riser.. Have you seen flames there yet?

If you NEVER see flames dancing around that secondary air, I suggest you close it off.

|

|

|

|

Post by woodrascal on Nov 15, 2013 12:50:06 GMT -8

When the cooker is being used it's impossible to see whether the secondary air causes a secondary burn - the top of the heat riser is covered by the cooker hotplates. By the way I've made an error in the caption on the firebox door picture (which I'll change). The slider shown controls the primary air. The secondary air feed is taken from underneath the cooker and is permanently 'open' - It can't easily be blocked off.

This is the manufacturers blurb about the secondary "Afterburn":

Afterburn2™ technology

The secret to the clean burning of the Woodfired ESSE lies in our unique patent pending Afterburn2™ flame jet system. Because the firebox is effectively a sealed chamber, the fuel can be burnt more efficiently at a slower rate and at a very high temperature. As flames, smoke and ash particles are pulled upwards by the flue, they are forced through a super heated stainless steel matrix where high temperature air is injected, drawing the flames into a precise shape and height, across the entire surface area of the matrix which can reach temperatures in excess of 1000° Fahrenheit. A second burn is then produced just below the incandescent matrix causing any smoke and ash particles to ignite, resulting in a very clean burn. Which in turn helps to keep the flue ways and chimney cleaner and ensures that maximum heat is produced from the fuel.

Incidentally had to send us three of these 'matrix' boxes as they kept failing. Eventually we gave up and used it without one and noticed no difference in performance or cleanliness of burn.

|

|

sos48

New Member

Posts: 1

|

Post by sos48 on Dec 1, 2013 18:43:52 GMT -8

I have same problem old conventional oven on our outside galley. I thoght to put heat tunnel in thru existing fire box,then exaust thru bottom of oven into chimney

woud that work?

|

|

|

|

Post by ronyon on Feb 1, 2014 21:26:24 GMT -8

|

|