Marc

New Member

Posts: 4

|

Post by Marc on Jul 2, 2024 10:12:24 GMT -8

If I could only find a glue that will stick the glass pieces together that would open up a lot more doors. I have tried quite a few possibilities with no luck so far! Hi Martyn, You simply wet the edges of the glass pieces, smear a little paste, assemble and hold while gently drying with a heat gun. Or leave to dry on its own.

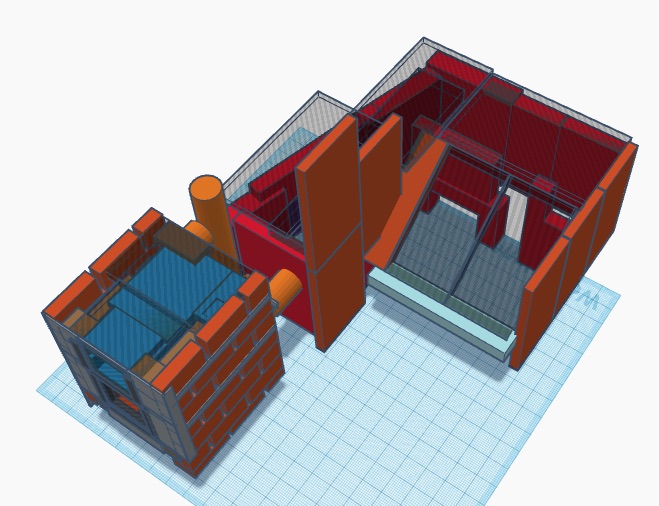

This piece I used for part of a firebox door:

p.s. maybe if you watch some of the videos by Sven Ekberg, you'll come across info that can help with healing your kidney (personally I'd try a few progressively longer water fasts, to get the benefits of autophagy).

|

|

|

|

Post by martyn on Jul 2, 2024 11:03:49 GMT -8

Hi Mar, nothing to loose so I will try the sealant and look at the videos…..

|

|

Marc

New Member

Posts: 4

|

Post by Marc on Jul 2, 2024 14:31:22 GMT -8

Hi Trev, I'm very grateful for the info you and others here (Peter, Matt, Martyn...) have shared, that was crucial in helping me build one of these efficient clean-burning stoves. And the vortex display, very useful for knowing what adjustments to make, and so beautiful! This is my first build, and the goal was a mass heater that would be cheap to build and run. The metal stove I had was wasting its heat up the chimney and barely heating 1 meter around itself. Now for the same amount of wood I get comfortable heat in a 3-4 meter radius that includes the staircase and keeps the whole house warm for hours after the fire goes out. I had seen J tubes on permies, and started planning for that. Then I found Matt's videos and his stratification chamber idea, which immediately convinced me it would work better than a barrel and pipes under cob, for my use. Then when I saw that he was happy with the change to Peter's batch box, I was convinced again. I read all of Peter's site, followed the link to this forum, and looked into DSR2 then 3. Then I chanced upon this thread, was impressed with the advantages of the vortex for a clean burn and maximum efficiency. And the mesmerizing visuals! For a couple weeks all my time in the evenings went into reading and trying to understand one post after another, while working on building the bell during the day. Instead of SketchUp I used Tinkercad online, easier to use without a mouse. Martyn's rapid prototyping outside reassured me it would be possible to recover, if I got something wrong at first. Which did happen: I had used 3cm thick pieces of the same stone I used for the bell (sourced free from a traditional open fireplace some neighbors were replacing), for the firebox roof and the top chamber roof, in order to save on vermiculite. By the 10th fire or so, after the first time doing a full load, when opening the stove to move the bypass higher in order to improve draw at startup, I saw both pieces were sagging and close to collapse, having turned into little more than powder. So I bought another vermiculite board and now it's all vermiculite from the firebox roof up. The rest is clay from a local field, mixed with one large bag's worth of perlite/vermiculite grains, and some local sand. And fire bricks for the outside. One more fire and I could have had to re-paint all the walls and ceilings! Total cost in materials around 300 euros, most of it vermiculite then flue pipes. It took a lot of time to plan and build, but I'm extremely happy with the results. It's now very easy to start in all weather, doesn't smoke, burns dry pallet wood cleanly, provides long-lasting gentle heat through the floors and walls... I can leave windows slightly open to get fresh air, and it's still nice and warm inside! Thank you, I could never have done this without following your lead! Here are some photos, for anyone interested:          |

|

|

|

Post by martyn on Jul 2, 2024 22:38:08 GMT -8

Well done Marc, you are a resourceful man.

|

|

Marc

New Member

Posts: 4

|

Post by Marc on Jul 3, 2024 6:11:42 GMT -8

Thank you, Martyn. Coming from you it's much appreciated!

|

|

|

|

Post by Vortex on Jul 4, 2024 0:45:35 GMT -8

Marc! Thank you for sharing your vortex stove build and your generosity. That's a great central position and use of normally wasted space.

I discovered the wonders of exhuast paste nearly 40 years ago, great for emergency repairs of broken stove glass, and more recently I found it's also great for sticking broken ceramic fiber board back together.

Trev

|

|

Marc

New Member

Posts: 4

|

Post by Marc on Jul 5, 2024 12:36:14 GMT -8

You're most welcome, Trev! By the way, I very much appreciate your welcoming attitude towards new users of this forum, that is visible when reading this thread and others

Another thing I've been impressed by, in the Vortex and Batch Box designs, is how the flow of air automatically balances the burning of wood in the front and back of the firebox. Because I wasn't sure I hadn't made mistakes, I started with partial loads stacked at the back, and it slowly dawned on me that air consumed by fire in front prevents fire at back from getting out of hand. Thus a full load will burn evenly front and back, at a constant rate. Brilliant design!

|

|

|

|

Post by fruitbat on Jul 5, 2024 12:45:27 GMT -8

Virtually all the latest models have a large burn chamber with lots of space around the wood, a slopping roof with secondary air, a restriction followed by an expansion area under the chimney. It's difficult to see how these designs prevent overfueling- the restriction is far larger than the ports we work with. And rather than all the combustion products heading through a relatively small port, the burn chamber vents through a strip. I'm sure there are clues in there somewhere, but it's a different mechanism! |

|

|

|

Post by martyn on Jul 6, 2024 0:13:08 GMT -8

Yes it seems like a different approach using a sealed, pressurised and insulated fire box combined with precision air control.

A few years ago the popular method seemed to use a heat holding fire brick baffle above the burning wood combined with secondary air pipes but now we have an insulated slopping roof with slightly cooler air.

I have lots of question to ask the staff but I really need to talk to the visiting rep who apparently will know the answers but, he only visits a few times a year.

|

|

|

|

Post by martyn on Aug 1, 2024 8:11:20 GMT -8

I have been speaking to the stove rep, he was fascinated with Trevs stove and seems to be genuinely interested in the vortex stove, unfortunately he is not the technical expert I really need to talk to but he did give me a few ideas …..

|

|

|

|

Post by Vortex on Aug 2, 2024 9:23:58 GMT -8

That reminds me a bit of hof 's Vortex build, he did something similar with the secondary air IIRC: donkey32.proboards.com/post/37020/threadI've been quite impressed with some of the new woodstove designs, both of my neighbors have one they've acquired in the last year, but like every other person I've met with one, neither of them have any clue what the various air supplies are for or how they're meant to be used, and don't actually care beyond keeping the class clear. A couple of potential issues; when you heat air very hot it expands up to about 4 times the size, and so contains only a quarter of the O2 of room temp air of the same volume. Those enclosed top corners might be cooled by the incoming air, and so could cool the gasses about to enter the port. Using heat from the firebox to heat incoming air always seemed like a zero sum game to me, but I look forward to seeing your experiments with it martyn. |

|

|

|

Post by martyn on Aug 3, 2024 1:39:52 GMT -8

Yes I understands your points but where there is a will……

I think a 10mm gap and a sliding control on the main inlet should cover the expansion issue, I could also have a feed behind the vermiculite coming trough 4mm holes in the same way as the factory stoves but the aim is to-reload a hot stove so I need to try my ideas. i think that is when the extra hot air may be required.

I am not in a position to build and try out this idea at the moment but hopefully later in the year I will have a go….

|

|

|

|

Post by martyn on Sept 23, 2024 3:17:38 GMT -8

lets see what we can do with two more sheets of vermiculite….

|

|

|

|

Post by martyn on Sept 23, 2024 8:45:19 GMT -8

One thing I tried out in the summer was a reverse flow, so the vortex was exiting at the back of the chamber away from the viewing window.

This was an interesting experiment and it gave a great perspective especially when the stove was over fuelling as the flams were now at the back looked really spectacular!

I think if I was to take this further, I would need to relocate the port closed to the front.

|

|

|

|

Post by martyn on Oct 8, 2024 5:13:14 GMT -8

Maybe, just maybe, I have found what I have been searching for…..

maybe I have found what I have been searching for…..

|

|