|

|

Post by satamax on Sept 9, 2012 8:57:23 GMT -8

Heyhey! I have a 80cm wide space. So some pouzzolane concrete flue elements. 350mmx350mm outside, two 8 element tower side by side. One 111mm tube plunging into the second one to the bottom or nearly. ;D www.beton-thebault.com/upload/Boisseaux.pdf500kg of mass, or thereabouts. Half of what i thought, but who am i to complain. I wonder how hot thoses would get? Cos i could go for 400x400mm outside dimension if that doesn't "fcuk" the old wallnut buffet and leather sofa which are each side. Tho, in this case i'll need a small barrel. |

|

|

|

Post by satamax on Sept 9, 2012 9:19:22 GMT -8

121.7 euros for the 12 blocks needed to make a 2metre bell, in 200x200mm inside size.

|

|

|

|

Post by peterberg on Sept 9, 2012 9:24:06 GMT -8

I have a 80cm wide space. So some pouzzolane concrete flue elements. 350mmx350mm outside, two 8 element tower side by side. One 111mm tube plunging into the second one to the bottom or nearly. ;D I wonder how hot thoses would get? Cos i could go for 400x400mm outside dimension if that doesn't "fcuk" the old wallnut buffet and leather sofa which are each side. Tho, in this case i'll need a small barrel. I would say, skip the barrel, use one of the bells instead to fit the stove in. The wider the bells are, the more wall area will be available to take up the heat. Use the largest you can fit in, those 350 mm square ones are way too small. Try to fit two 400x600 mm items beside each other and move the sofa a little bit. The weight will go up to 672 kg plus the top plates. How hot will they get? The larger ones could be about 100 C., tops. Oh, and the hottest spot will be close to the top of the bell. Please don't use one of those 111 mm tubes to connect those bells, it's definitely too small. Better use 156 mm, which is nearly system size. Apologies to all you people who aren't used to metrics, I'll promise to try to stick to measurements you can comprehend. Edit:I've checked your SketchUp file and this larger liners are beautifully sized for your scheduled firebox. |

|

|

|

Post by satamax on Sept 9, 2012 13:25:21 GMT -8

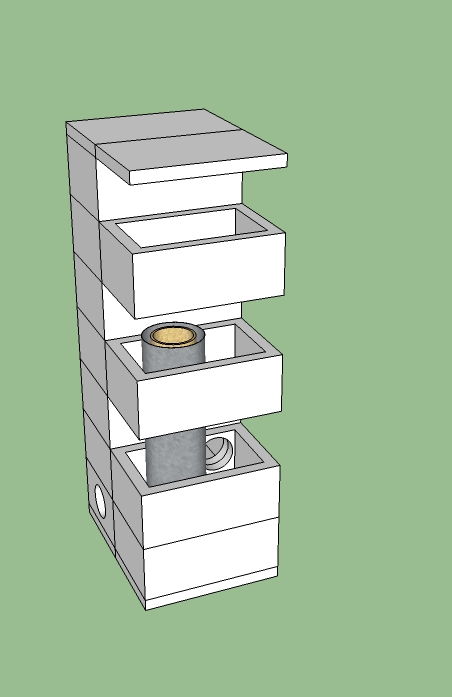

Peter, i think in this case, there's not much choice, i can't use anything else than 111mm tubing But it works on my 6 incher J tube gaz bottle rocket. Worth trying in this case. Hope ye like it!  Guys, for thoses that aren't savy with sketchup, you can hide/show components to see the internals. Pretty much everything is to size  Attachments:

|

|

|

|

Post by satamax on Sept 9, 2012 13:35:14 GMT -8

A hiden part view showing the details!  Peter, thoses pouzzolane blocks don't risk spliting with the heat? I was thinking, use high temp silicon caulking to joint them? I realy need to order some 12cm refractory tube, i could then make a nice small one. Nother thing, instead of the baffle on the right side, i could use two line of 300mmx300mm blocks, one for the up stream, the other one for the down stream with the pipe in it. Attachments:

|

|

docbb

Junior Member

Back from ZA

Back from ZA

Posts: 92

|

Post by docbb on Sept 9, 2012 17:58:53 GMT -8

cyclone burning chamber with horizontal P-channel ?  |

|

|

|

Post by satamax on Sept 9, 2012 23:07:50 GMT -8

Hey doc, me like the idea  |

|

|

|

Post by peterberg on Sept 9, 2012 23:52:18 GMT -8

|

|

|

|

Post by peterberg on Sept 10, 2012 0:06:22 GMT -8

Peter, i think in this case, there's not much choice, i can't use anything else than 111mm tubing. But it works on my 6 incher J tube gaz bottle rocket. Worth trying in this case. Hope ye like it!  Of course your stove do work, but not in an optimal fashion. The difference between stove internals and chimney c.s.a. is too big. This batch box construction is much more effected by a low gas velocity. It will produce heat, yes, but you won't utilize the excellent properties of this gizmo. The smaller duct you mention is only 50.6% of a 156 mm (6") duct. Waaaay too small. I will look into your drawing, comments later on. It's best to order the smaller duct version of about 5". Don't forget the firebox has to be scaled down a bit as well. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Sept 10, 2012 1:23:39 GMT -8

Hi It's always the same, how to get good contact between mass and tubing? When you have no clay. Why not order online ? In Germany one can get 25 kg of powdered clay starting at about 11 €, including shipment less than 20€. |

|

|

|

Post by peterberg on Sept 10, 2012 2:14:59 GMT -8

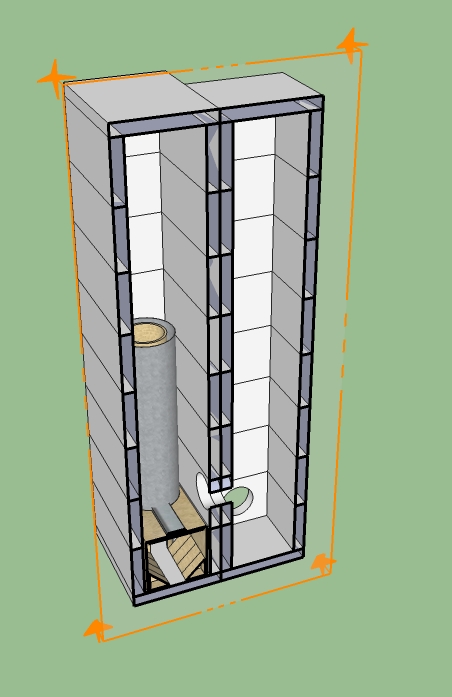

Peter, thoses pouzzolane blocks don't risk spliting with the heat? The way as you have drawn them they will crack, yes. The riser is much too long, the top parts will be too hot this way. The bell at the right isn't a bell at all like that, it's a double contraflow path. This will be heated uneven as well. The beauty of a bell setup is a fairly uniform heat distribution, you'd be much better off with that. To show what I do mean by that:  The riser is shorter, only 80 cm (2.6'), measured from the firebox. Exit hole from first to second a little bit higher up, this way you are able to place a layer of vermiculite around and on top of the firebox. No baffles nor pipe in the second bell. Exit hole from second bell low at the back. This is a true bell system, and I'm very sure this would work without a flaw. Optimal use is been made here of the low friction properties of such a system. And yes, I know you don't have enough space to place the exhaust pipe at the rear of the stove. This could be a solution to that problem:  The right side bell is made out of square 40x40 (1.3x1.3') puzzle blocks. To compensate for the loss of wall surface I've added one on top of each bell. This is even better than the former proposal because the riser end is farther away from the top of the bell. The height difference between the inlet and exit of the second bell is needed here, so this is a happy coincidence. Here are both the amended files: pberg0.home.xs4all.nl/pictures/Batchbox/maxhorizontal ocket2.jpg pberg0.home.xs4all.nl/pictures/Batchbox/maxhorizontal ocket3.jpg And yes, you could use high temp silicone to join the blocks. Not the faintest idea how long it will last, though. This setup has the great potential to make a fine stove and being moveable as well. Please don't be conceitedly about this, don't use pipes inside bells, don't try to move the gases up and down several times, stick to these principals and refrain from deviations (again). ;D Edit:What's the reason behind you not being able to use other chimney pipe than 111 mm (4.37")? |

|

docbb

Junior Member

Back from ZA

Back from ZA

Posts: 92

|

Post by docbb on Sept 10, 2012 7:13:06 GMT -8

The riser is much too long, the top parts will be too hot this way. Dear Peter what's the relationship between the riser hight and the exhaust temp at the top of the riser? You know my plan is to build an bread/pizza oven withe a separate furnace. Do you think that the oven itself could be a good afterburner or is it too wide eighter not high enough? I.E. Flame entering right in the oven after the "letter box"and hitting a baffle wall |

|

|

|

Post by satamax on Sept 10, 2012 9:46:56 GMT -8

Hi Peter. Well, the reason is that the hole into the wall is for 111mm pipe. Thought with your solution of having the second row of blocks smaller, i could use the sweep's hole. I was thinking of using taller a heat riser to enhance the push through the ups and downs  One question, are you sure the the 40cm bell won't bypass? I went to my local supplier, and he hasn't single wall pouzzolane blocks, just double ones. And no 40x60. Need to check the other one. |

|

|

|

Post by peterberg on Sept 10, 2012 10:10:08 GMT -8

Dear Peter what's the relationship between the riser hight and the exhaust temp at the top of the riser? Honestly, I don't have a clue. The riser height provides the letterbox with gas velocity, so a longer riser equals a more rapid stream. The net result would be more heat out of the riser end. On the other hand, a longer riser is also providing more mass. These two facts on their own will influence the end result enormously, let alone all the other factors which are in play. Do you think that the oven itself could be a good afterburner or is it too wide eighter not high enough? Yes, an oven holds too much mass, is too wide and too short. The length of the riser compared to its circumference dictates the speed, without this balance, this stove wouldn't be any good. |

|

|

|

Post by peterberg on Sept 10, 2012 10:22:02 GMT -8

I was thinking of using taller a heat riser to enhance the push through the ups and downs  That's the beauty of a bell, no need to push, the gases will segregate by itself. One question, are you sure the 40cm bell won't bypass? No, it won't, I am very positive about that. Assuming the hole between the bells is about 6", the widening of the bell behind it is 4.7 times. Should be perfectly adequate, the substantial height difference between this and the exhaust will do the rest. Hope you'll be able to find the right blocks. |

|