|

|

Post by peterberg on Aug 16, 2012 11:31:50 GMT -8

No luck so far, the larger channel didn't do what I've hoped for. Switching back to the 6.8% channel wasn't working satisfactorily either. The next day, I've removed the half brick part off the firebox walls and tried the 6.8% part again. This also wouldn't do what it's supposed to, so I'm fed up with this stubborn and unpredictable stove for the moment.

I'd take a few days off to sort things out and wait for inspiration!

|

|

|

|

Post by peterberg on Aug 20, 2012 12:39:00 GMT -8

The above mentioned inspiration did come. I've carried out two testruns using an unusual configuration. The ratio between riser and front c.s.a. has been about 1 to 4, the p-channel about 6.7 % of the riser, tunnel opening 70 % of the riser. Nothing special in this department. But... the front opening wasn't restricted in any way. In fact, I was using the thing as a mini open fireplace with an afterburner behind it. In any case, it had the looks and sounded like one as well. To my surprise, the resulting graphic was really outstanding!  High res: High res:Mind you, this was a run started in a cold stove. The usual CO mountain in the beginning wasn't there at all. This burn was executed in real rocket mass heater style, open feed tube and roaring like Shrek himself. The averages were pleasing as well: O2 13.2 %, eff. 74.5 %, CO 388 ppm, end temp 256 C. Refilling has been done at 46 minutes and 60 minutes. No sign of an overload, on the contrary, the CO went down sharply because of those actions. I'm a firm believer of bringing the good news only when it is confirmed. A good experiment is transferable and repeatable. So today, I've ran another test in hopes to confirm my findings.  High res: High res:I've done this one without refilling, started cold, the front side slightly restricted to about three quarters of the total opening. Nothing changed in the appearance and the sound, by the way. The only action on my part has been shoving the glowing embers to the back at 31 minutes. Averages: O2 13.6 %, eff. 74.8 %, CO 359 ppm, end temp 255 C., not much difference compared to the former one. The Testo filters of both these runs were very, very, very light grey, off white so to speak. End temp and oxygen were on the high side. As a consequence, the efficiency has been rather low, this could be resolved by placing another 55 gallon barrel on top of the first one or adding a bench. Next goal: testing how this stove would behave without a p-channel. Actually, I think I do know how it will perform, but I do need to know for sure. |

|

|

|

Post by peterberg on Aug 24, 2012 8:52:04 GMT -8

As I've mentioned in my post before this one, during the next couple of testruns the p-channel was blocked off. This first run turned out to be an unexpected surprise. The fuel has been stuffed up to the ceiling of the firebox. Since I do know of other occasions when it will go wrong, it will do so in the most terrible way. Well, it didn't. Please have a look at the diagram below.  High res: High res:The stove was started from cold, no warming-up fire. Just a handful of small kindling and at the time this was burning well (read: roared) the firebox was fully loaded. This run started unexpectedly rather nice, and I had to wait for 15 minutes before something went wrong. The CO went up very steep to 52000 ppm, stayed there for full 2 minutes and came down the same way. After that, things were running very smooth. Despite the steep peak, the average carbon monoxide level was as low as 1344 ppm. Not good enough for the Austrian' rules, but close. Remember, the tunnel is only 70% of the riser c.s.a., a letterbox opening on its side. Behind the tunnel the space widens abruptly, resulting in a lot of turbulence. That's why this stove is roaring violently from start to finish. Since in the chimney there's still some oxygen in the gases, it's best to keep this as low as possible. It looks like this "thing" is able of consuming a lot of this excess oxygen. After I've had a good night sleep over it, I've tried it again. This time leaving out the p-channel altogether and not loaded to the top but above the fuel an open space of just 2".  High res: High res:This graphic is one of the best I've seen from this stove. Started from cold again, the start-up CO-mountain isn't there at all, end CO is very moderate. Averages are: O2 12.6 %, eff. 76.2 %, CO 270 ppm, end temp 257 C. Efficiency could be higher, of course, but the CO and O2 lines hardly couldn't be better. But... I wasn't convinced yet, so I've loaded the hot stove, as far as doable and up to the ceiling again.  High res: High res:This one is very nice as well, the small overload was corrected, CO rose again, corrected again and 3.5 minutes later it went back to the bottom of the scale. Mark the extra low oxygen level, which normally comes together with a smoking stove. This is an excellent result, especially as performed by a stove of such a simple construction. Next goal: rebuilding the thing, equipped with a letterbox tunnel opening higher and narrower than before. |

|

docbb

Junior Member

Back from ZA

Back from ZA

Posts: 92

|

Post by docbb on Aug 26, 2012 23:51:04 GMT -8

Hello, I am new here, from Reunion Island in the Indian Ocean, I have in mind to build 3 complexes "pizza/bread oven-cookstove-Tandoori oven" fired in a serial mode and keep looking for an "Engine" for all in once if suitable. I really do appreciate your work Peter, it's of a huge value and a "non such" on all the internet I know at the moment. this time, I have some diffuculties to figure out the way you have built your engine : 6 times higher ok but it makes a 16,6% , not 5% from the top of the fire box , or ...? -could you precise what is the "active channel" : the entire firebox? or the junction between firebox and the riser (like the horizontal part in the "J" shape ones ? -when you says "letter box" is it the kind of device you described in your syphon-bell-rocket-mass heater? may be a little drawning could help us to figure what you are building. What do you think of the so-called "BIO Firebox" developped by A. Chermov from Stovemaster.com, isn't it kind of the same principles : pre-heated "fresh" secondary air (between firebox and brick cover), unilateral letter box slit and trip wire from crenels ?  and, excuse me for my poor english, what do you mean by "c.s.a." ? thank you again for publishing your researches. |

|

|

|

Post by peterberg on Aug 27, 2012 6:24:00 GMT -8

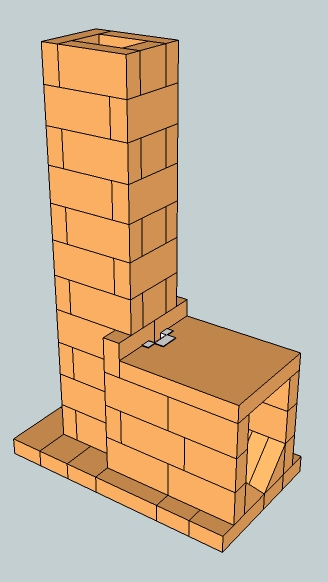

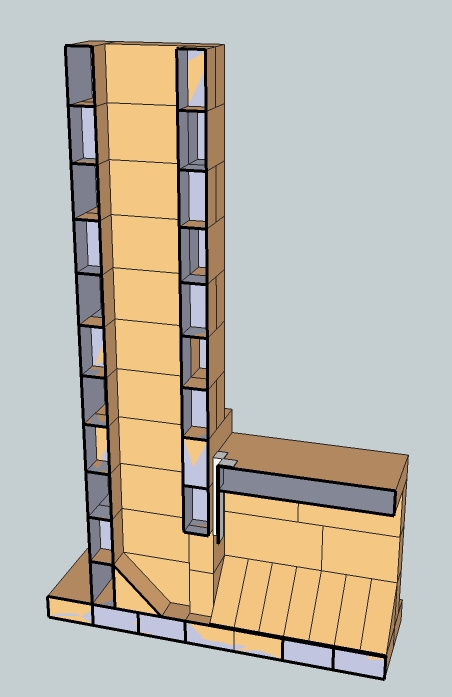

this time, I have some diffuculties to figure out the way you have built your engine : 6 times higher ok but it makes a 16,6% , not 5% from the top of the fire box , or ...? Hi docbb, welcome to the forums. First, the tunnel is the opening between the firebox and the heat riser. Second, the p-channel is a small U-shaped stretch of steel, the c.s.a. of this is between 5% and 6% of the riser c.s.a. (cross sectional area). This piece of steel hangs down just above the ceiling of the tunnel. Some of this steel is inside the firebox and will become awfully hot. This is what I'd call the active part of the p-channel. The riser, measured from the ceiling of the tunnel upwards, should be at least 6 times as long as the active channel. Here are some pictures:  This is a sectional drawing:  And here's the Sketch-Up drawing itself, this is how I've built this stove. Mark however, this is still in a very experimental stage. pberg0.home.xs4all.nl/pictures/Batchbox/horizontal.skp-when you says "letter box" is it the kind of device you described in your syphon-bell-rocket-mass heater? No, that's an entirely different concept. There are some similarities of course, but this latest development is much, much simpler. The firebox of Alex Chernov isn't the same as the BIO firebox, but the picture is Alex'. This is a very large stove of a totally different construction. The firebox in the picture is an older concept, by the way. Alex has been changing some important features. The slits left and right aren't there anymore, the holes in the side and back walls have been skipped as well. He is using two smaller floor grids now, one in front and a very small one at the back. |

|

|

|

Post by peterberg on Aug 27, 2012 7:02:42 GMT -8

Last week I've been busy with another model of the batch box rocket. This time a composition of two cast pieces and an insulated heat riser out of steel. The riser is a hexagon, the tunnel is very high and narrow. All been made for a specific demonstration purpose. This is how the cast half looks like:  High res: High res:The riser is made out of a stainless steel 6" duct and some tins which formerly contained peanut butter. At first, the stove smoked a lot, but once the refractory came up to temps and dried somewhat things went fairly smooth.  High res: High res:Finally, after 6 attempts I've managed to shoot a short video of what was actually happening inside the riser. The firebox wasn't loaded for more than a quarter, the burn has been on its way for 15 minutes. I've used a quite high rung ladder, with my hands being away about 6 ' from the top of the riser and helped by some side wind I could stand it for about 30 seconds. As can be seen, the flames are coming through the narrow tunnel at the right hand side, expanding rapidly. At both sides these are curling horizontally and coming back to the tunnel opening again before rising. It looks like a double ram's horn pattern. This is a sight to be seen, the rather tame looks at the front doesn't prepare the innocent spectator for the rapidly moving flames, like a waterfall. The square or rectangle risers do behave a little bit different, but according to the Testo it's still in the same league. Today I've had a temperature sensor in there, about 4" above the riser floor and brought in horizontally at the back. Shortly after this video the digital thermometer showed a temp of 1830 F. and I had to pull the sensor out. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 27, 2012 8:38:28 GMT -8

peterThe stream of fire in the video looks impressive. Thanks for sharing your huge lot of information. Regrettably I have only a condo in Germany without space for such experiments.

|

|

|

|

Post by satamax on Aug 27, 2012 9:07:27 GMT -8

Peter, i think it could be intresting to see what it does with a tangential intake into the heat riser, instead of the central one. It's again a daft idea of mine about cyclonics  My idea is when you get a cyclonic motion, it might burn for longer with the spiraling in the heat riser. Ok, less turbulence than this one, but may be the draft could be even bigger. That ram horn flame patern makes me think of a barley shaker cyclone. Don't know why! Thanks a lot for sharing. Your "fireplace" rocket might take place into my flat quite soon. Daft question, is it necessary to have the V shapped bottom in the firebox? |

|

|

|

Post by peterberg on Aug 27, 2012 10:47:07 GMT -8

Daft question, is it necessary to have the V shapped bottom in the firebox? No, it's not necessary, it doesn't contribute much to the burn as far as I can see. However, in the last phase of the burn the glowing coals will concentrate in the middle and keep the temperature high. As a result, less charcoal will be left over. |

|

|

|

Post by satamax on Aug 27, 2012 10:55:31 GMT -8

Thanks a lot Peter.

|

|

|

|

Post by satamax on Aug 27, 2012 13:56:07 GMT -8

Nother question, will you insulate the firebox soon? And what about puting a barrel over it? Should be possible by now?

|

|

|

|

Post by peterberg on Aug 28, 2012 2:03:35 GMT -8

Nother question, will you insulate the firebox soon? And what about puting a barrel over it? Should be possible by now? As I mentioned earlier, the primary goal is a demo, to be held coming Saturday. The whole thing has to be transported over about 100 miles. So, insulating the firebox isn't really practical at the moment. At the demo site itself there are two 55 gal. barrels waiting to be stacked on top of the cast pieces. The metal riser assembly will be inside the lower barrel by then. In fact, the two barrels together will form a metal bell construction with the exhaust at the lower side of the lower barrel. Could be quite interesting what temperature the exhausted gases will be, don't you think? And I'm very curious whether or not the stove could deal with this major heat extraction. |

|

docbb

Junior Member

Back from ZA

Back from ZA

Posts: 92

|

Post by docbb on Aug 28, 2012 5:57:25 GMT -8

And I'm very curious whether or not the stove could deal with this major heat extraction. Do you think it could be a good "engine" to heat a pizza/bread oven in the way of a traditional french "four à gueulard" bread oven ("schreeuwer " in nederlands ?¿) like ins this video since 1:23" |

|

|

|

Post by peterberg on Aug 28, 2012 8:38:31 GMT -8

docbb, Could be, yes. The riser should open into the oven which in turn would act as a bell. The exit from the oven should be low again, to keep the majority of the heat in the oven.

|

|

|

|

Post by satamax on Aug 28, 2012 11:31:24 GMT -8

Peter, i'm looking forwart to your demo test results  |

|