|

|

Post by Rinchen on Mar 9, 2012 4:30:19 GMT -8

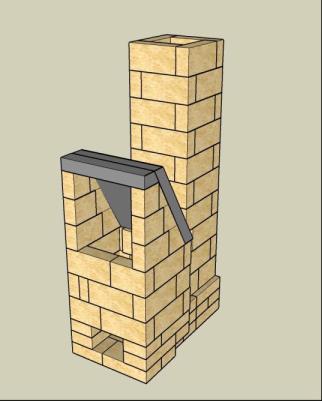

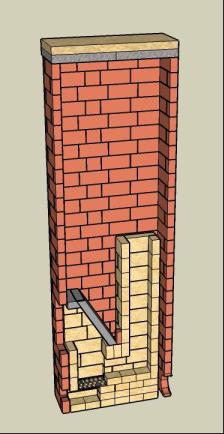

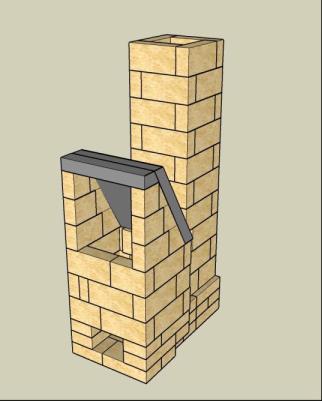

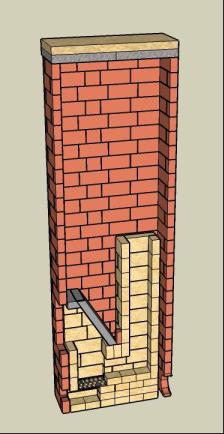

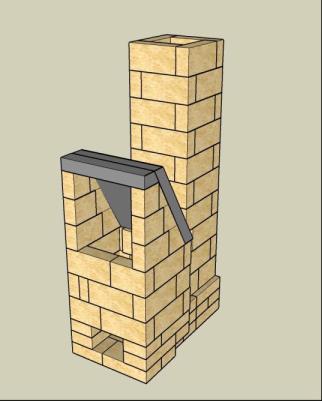

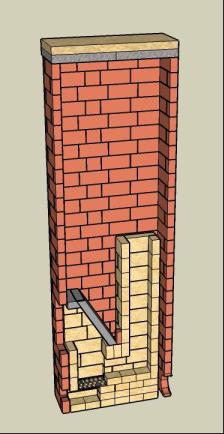

We have happily been using our (near) 8" standard J-tube/barrel/bench system for a few months now. For the next winter I am thinking about what I can do to make a bigger firebox. Of course Peter's Rocket/Bell is well designed and tested, but is a little tricky to adapt to an existing RMH. I think a good starting point is Peter's first iteration:   Today, I had a go at a stable firing session. With a very little bit of under air and all the air I could add through the loading door without getting smoke in the workshop. It appears to be quite successful, no sky high CO-readings and efficiency within a range of 80% to 97%! As you can see from his quote this could already provide a good solution to modify an existing J-tube for one who does not need the absolute maximum results. As far as I can see all the developments after this by Peter (including the development on the small Rocket Stove) are to improve secondary air delivery and mixing. The results for a standard J-tube resulted in the "Peter Channel" and the trip wire. I suppose you could add these to the design shown above to improve on it. What I find interesting is that on the latest wood gasifiers on the market they use a nozzle that is quite small to seperate the firebox from the burn chamber and inside the nozzle is the secondary air delivery. Like this:  In this video they also show a nozzle taken out of the heater: I think the nozzle would increase the temperature of the gas stream because it has to pass through a small area and it will give excelent mixing with the incoming secondary air. As an experiment I created a throat before the burn tunnel this morning after the Rocket was well heated. Like so:  The burn tunnel is 16cm high and 18cm wide. The bricks are 5cm wide, so the throat is effectively only 45% of the burn tunnel. I have taken some bricks away in the drawing to make the throat visible. Of course I could not stuff much wood in (oak +-5x5cm), but surprisingly it ran VERY well. The flames became bright yellow and even some purple could be seen. The coals in front became bright white. The power output seemed comparable with a fully loaded feed tube. I only ran it for five minutes because I was concerned for the bricks which are normal concrete bricks (dont try this at home). When I picked them out the bottoms were glowing red!  So far I have not seen the chamotte stone this hot in a standard configuration. When the bricks were taken out the fire returned to a very lame fire in need of more wood. I have not provided any provision for secondary air. This was just to test how it would respond to a nozzle. I think this is encouraging for further testing and the refractory used for the nozzle should be easily replaceable, because it is under heavy heat stress. |

|

|

|

Post by canyon on Mar 9, 2012 9:15:23 GMT -8

Rinchen, I appreciate your post, I have been working on nozzles and horizontal batch loading for some time too. I still have a bit more to do for solid conclusions (including testo data) but am encouraged by the results. I agree that the nozzles need to be simple refractory that are easily replaceable. Also inspired by Peterburg (his copper 2ndary air pipes) I started with sch. 80 steel pipe and have found it too short term. I have built a few large burn chambers with a masonry arch top and am working on a kit for diy'ers. I am going on tour with it and hope to see what some other rocketeers can throw at it and help refine it. I am not so advanced as you in the sketchup scene, but my friend is with some other program and he has done a good rendition that I hope to share if I can figure out how to. But likely not for a bit as I am busy and would prefer to share it after my trip so stay tuned. I look forward to collaborating!  |

|

bud

New Member

Posts: 11

|

Post by bud on Mar 9, 2012 12:25:53 GMT -8

I'm not much into the theoretical aspects or the physics, and I haven't build the mass heater yet, but it seems to me that Donkey has already provided a workable example of a larger capacity, batch-load firebox without all the fun and games of complicated or hang-up(literally) prone auto-feed systems. His "stove at home" posts show it pretty clearly. Why not adopt it to your heater? Reinventing the wheel isn't always necessary.

|

|

morticcio

Full Member

"The problem with internet quotes is that you can't always depend on their accuracy" - Aristotle

"The problem with internet quotes is that you can't always depend on their accuracy" - Aristotle

Posts: 371

|

Post by morticcio on Mar 9, 2012 16:03:38 GMT -8

The nozzle on the floor at 1:40 in the video a row of holes (for the secondary air delivery?).

What if you were to drill a row of 4 or 5 holes vertically on the throat bricks to replicate this?

|

|

|

|

Post by chrisz on Mar 9, 2012 16:39:26 GMT -8

Just so I am understanding this properly, What you have going here is a "batch" of wood placed in a pile in front of the J tube (all contained in a fire box)...next a nozzle (or funnel of sorts) and then the j tube of a "normal" rocket.

cz

|

|

|

|

Post by peterberg on Mar 11, 2012 3:00:53 GMT -8

Rinchen, I've been reading your original post several times over and I keep stumbling over this phrase: "after the Rocket was well heated". When hot, the rocket seems to run better with this modification is the only established fact up til now. But, when implemented, you have to start the thing with the extra bricks inside. Maybe it's best to try that a few times to see whether this will work or not. And when it does, can I come along with the Testo equipment to do a full test run? After all, we do live only about 30 miles apart.

|

|

|

|

Post by Rinchen on Mar 12, 2012 2:51:46 GMT -8

I'm not much into the theoretical aspects or the physics, and I haven't build the mass heater yet, but it seems to me that Donkey has already provided a workable example of a larger capacity, batch-load firebox without all the fun and games of complicated or hang-up(literally) prone auto-feed systems. His "stove at home" posts show it pretty clearly. Why not adopt it to your heater? Reinventing the wheel isn't always necessary. Hi Bud, Thank you for pointing that out. I had read about Donkey's heater in the book, but I didn't know there was a topic about it here. It sure is a workable example, yet it is not exactly what I am looking for. I am looking for a solution for people that have already build the standard J-tube and would like to add a firebox with minumal fuss. Besides that, Donkey's solution to my inexperienced eyes looks more like how a masonry oven is build, with the flue replaced with a square riser with cardboard insulation. You are right about not reinventing the wheel when you want a solution that works, which is why I suggested using Peter's first iteration with a trip-wire and "Peter Channel" added. I think that will give a pretty good solution. But I like a bit of experimenting (within time available) and I think that in this area there is room for it and we would gain some more experience in what works and what doesn't. |

|

|

|

Post by Rinchen on Mar 12, 2012 3:10:43 GMT -8

The nozzle on the floor at 1:40 in the video a row of holes (for the secondary air delivery?). What if you were to drill a row of 4 or 5 holes vertically on the throat bricks to replicate this? Hi that would be the next step to think about the air delivery. In your suggestion I would move the holes to the inside though, like this:  |

|

|

|

Post by Rinchen on Mar 12, 2012 3:20:58 GMT -8

Just so I am understanding this properly, What you have going here is a "batch" of wood placed in a pile in front of the J tube (all contained in a fire box)...next a nozzle (or funnel of sorts) and then the j tube of a "normal" rocket. cz Hi crisz, I think you understand what I mean. Just to make it clear: after the nozzle comes the burn chamber and riser. The nozzle would be a restriction in the first 5cm of the burn tunnel. |

|

|

|

Post by Rinchen on Mar 12, 2012 4:09:07 GMT -8

Rinchen, I've been reading your original post several times over and I keep stumbling over this phrase: "after the Rocket was well heated". When hot, the rocket seems to run better with this modification is the only established fact up til now. But, when implemented, you have to start the thing with the extra bricks inside. Maybe it's best to try that a few times to see whether this will work or not. And when it does, can I come along with the Testo equipment to do a full test run? After all, we do live only about 30 miles apart. Hello Peter, I have this weekend tried two other configurations as well and have had the brick in from the start till the end. The configurations I tested was a 5x10cm brick, slightly shorter then the width of the burn tunnel, either flat or on its side inside and on the bottom of the entrance to the burn tunnel. This time I used a high temp. fired clay brick. Cold start is a little tricky on my system, because at around 10 minutes from start it is having doubts which direction to burn :-) This can last for a few minutes until the riser starts heating up and pumping more exaust gases out the chimney which in turn starts to see a small temperature difference by then. At this point I can start adding more wood and after that the draft is always very strong and I never get smoke back. I have not noticed the startup to be any different with the brick installed. For me I can only measure power output at the barrel by measuring the temperature on the same spot and I can tell how well the fire is burning. I have not noticed a difference in power output with a brick installed. even when the entrance is reduced to about 42%. Power output is enough to heat a multilayer tinfoil oven (see Ianto's book) on top of the barrel to 260C/500F. So we had some lovely pizza, pouched potato's, fried aubergine and paprika and pouched banana's this weekend :-) What I have noticed is that there is a thicker layer of coals, which get white hot, when the brick is on the bottom of the burn tunnel. This radiated more heat into the feedtube which caused the wood to be burning even a little higher then the top of the feed tube. Draft is very strong so the flames go straight down in my system. I dont think making a nozzle by constricting the top and/or bottom is the way to go. I have tried the brick flat as well as standing on its side which varied the height between 5cm and 10cm. When I observed the flames the path is not very different from normal operation, unlike the bricks being on the left and right side. My thinking on this is that there is already a nozzle effect going on because of the natural forces involved. The hot flames want to rise, so will already come off the floor, the colder air is coming in from the top, pushing the flames down again. Most time during operation (without bricks to obstruct) this is exactly what I observe. However sideways there is no forces acting on the stream, which is why I saw a significant difference when two bricks were placed on the sides. Thank you for offering to measure the system. That is the only way to tell what difference the nozzle would make in improving the combustion. I think it would be worth it to have some more configurations to test. Including a provision to deliver the seconday air. So perhaps it is still too early to do a testrun on merely having a nozzle in the burn tunnel? Or do you think this can already provide usefull information? The heating season is coming to its end now in the Netherlands, so I am planning to make a setup outside mainly to test firebox configurations. The nozzle is basically a side-track from this because it is not strictly necessary for a working firebox. It can however provide some very interesting new material for efficient homemade woodstoves, which is why I started the topic. The test setup outside will unfortunately have to wait till the sittingroom is done (finish bench properly, take old carpet out and replace with something else) |

|

|

|

Post by Rinchen on Mar 12, 2012 4:47:30 GMT -8

|

|

|

|

Post by peterberg on Mar 12, 2012 9:02:48 GMT -8

So perhaps it is still too early to do a testrun on merely having a nozzle in the burn tunnel? Or do you think this can already provide usefull information? Honestly, I would think it's best to test the stove in standard configuration first. Very few have been tested this way, so this will provide some data as how a J-tube performs for future reference. Testing the stove with the changes in place isn't very useful if you don't know whether or not the changes are improvements compared to the original stove. Admittedly, the Testo equipment is very unforgiving, but it's better to know what the performance really is like. |

|

|

|

Post by Rinchen on Mar 13, 2012 0:28:19 GMT -8

So perhaps it is still too early to do a testrun on merely having a nozzle in the burn tunnel? Or do you think this can already provide usefull information? Honestly, I would think it's best to test the stove in standard configuration first. Very few have been tested this way, so this will provide some data as how a J-tube performs for future reference. Hmm this is indeed very usefull information for many. I read this article by Alex Chernov. mha-net.org/docs/temp/111128alex.pdfAnd the lack of proper testing data on Rocket stoves led him to stick with masonry heaters. I will be engaged for about two weeks from the 21st and after that there will be less days available for needing heating, so then it would have to be this week. I will have to discuss this at home to see when would be possible. Can I send you a PM about making an appointment? Thank you for wanting to take the time on this. I am sure other people would like to see the results as well. Testing the stove with the changes in place isn't very useful if you don't know whether or not the changes are improvements compared to the original stove. Admittedly, the Testo equipment is very unforgiving, but it's better to know what the performance really is like. Hihi, indeed for proper testing it is a must. For practicality though the stove has very much proved its merits already  |

|

|

|

Post by peterberg on Mar 13, 2012 1:12:37 GMT -8

Can I send you a PM about making an appointment? Yes, please do. |

|

|

|

Post by Donkey on Mar 13, 2012 6:53:46 GMT -8

Well.. I've never been quite satisfied with my stove at home.. Looks to me like this might be just the ticket to change that.

I'm excited about this and look forward to your results.

|

|

So far I have not seen the chamotte stone this hot in a standard configuration. When the bricks were taken out the fire returned to a very lame fire in need of more wood. I have not provided any provision for secondary air. This was just to test how it would respond to a nozzle.

So far I have not seen the chamotte stone this hot in a standard configuration. When the bricks were taken out the fire returned to a very lame fire in need of more wood. I have not provided any provision for secondary air. This was just to test how it would respond to a nozzle.

So far I have not seen the chamotte stone this hot in a standard configuration. When the bricks were taken out the fire returned to a very lame fire in need of more wood. I have not provided any provision for secondary air. This was just to test how it would respond to a nozzle.

So far I have not seen the chamotte stone this hot in a standard configuration. When the bricks were taken out the fire returned to a very lame fire in need of more wood. I have not provided any provision for secondary air. This was just to test how it would respond to a nozzle.