|

|

Post by peterberg on Jul 28, 2008 8:31:46 GMT -8

Last week I had a go at another test run. With fixed settings for under air (ash door) and loading door. It all went very well, used all soft wood. Started with 6 pounds and did a refill at 46 and 76 minutes, 4 pounds each. Total length of the test: 106 minutes. When somebody is very interested in the fixed air intake settings, I am able to recalculate the measurements. And here is the link to the graphic: www.pberg.demon.nl/pictures/large/test220708b.gif It's a bit too large to incorporate in the forum, sorry. Largely self-explanatory I would think. The three horizontal lines with the marginal notes 13% O2, 70% eff. and 3000 ppm CO are the European checkpoints whether the stove would stand a chance to pass the emissions test. In fact, the efficiency has to be above 70% and the CO below 3000 ppm, at the same time as the O2 reads 13%. I began this test series with sky high CO readings, like 7500 ppm at some point. There are still two smallish peaks above the 3000 ppm line. I regard this as a "work to be done" indicator. |

|

|

|

Post by chronictom on Aug 22, 2008 12:03:26 GMT -8

On the matter of starting draw when cold, could you not add a small firebox near the end of the stove (at the base of the chimney)?

Light a quick fire in it, once it's going hot, close the vents off so it has start drawing through the rest of the stove?

Tom

|

|

|

|

Post by chronictom on Aug 22, 2008 18:22:11 GMT -8

Ignore that.. obviously its not a very original thought around here... lol

|

|

|

|

Post by peterberg on Aug 24, 2008 0:29:13 GMT -8

Maybe I wasn't very clear about this, but the thing has had no start-up problems at all after the initial drying period. The workshop is equipped with a regular chimney. Masonry, section 7" square, height 30'. Not very quick warmed up, on the other hand a small but very stable draw. Even with the stove exhaust temperature the same as room temp, the stove didn't puff back.

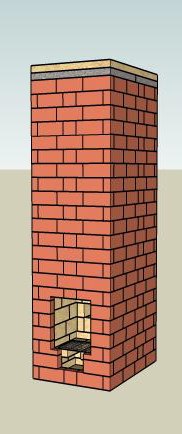

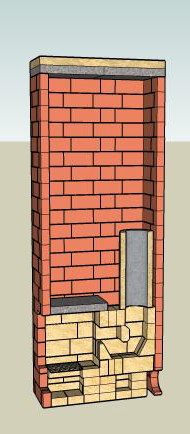

The prototype stove shown in the pictures has been taken apart and I am building slowly away at the next one. The internals has been changed 2 times, footprint is a bit wider, loading door lowered, heat riser 2 feet high and insulated stainless steel. Still be built as a single bell, to be able to compare the two.

As soon as the changes are complete and the thing is rebuilt and fired again, I'll post pictures and revised drawings.

|

|

|

|

Post by peterberg on Sept 2, 2008 6:38:09 GMT -8

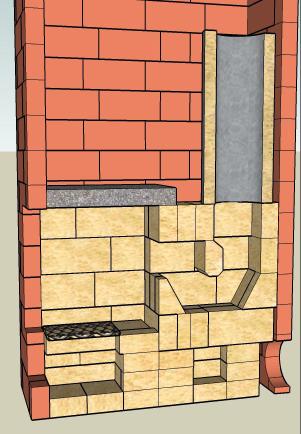

Here I am again. The second iteration of the bellrocket/rocketbell has been completed. As can be seen at the drawings and pictures, on the outside is not much difference. The loading door has gone down on top of the ash door, width is up 4", height is down 1' 4". The cubic feet internal remains the same as the former prototype, about 28.5. Heat distribution is better, end temp is a bit lower. Too low for first fire, the end temp descended under room temperature and the smoke came out. And condensation fluid came dripping out the seams of the door. The penalty for lighting a wet stove.     The internals however are quite different. In fact it is a firebox of 1' square with a rectangle hole in the back wall. Behind that is a horizontal fed rocket with a twist in it. It drops down 4 inches first, then a very short burn tunnel of 2", to end in a heat-riser of 1' in firebrick with an 1' 8" insulated pipe on top of that. The whole twist and riser assembly is 6", the same cross sectional area as the flue pipe.    It's early days yet, but the thing seems to work satisfactorily. The Testo analyzer is very happy anyway. At the same moment as the muffled and slightly distant roar do start, the CO goes down and the efficiency goes up. The same pattern for 3 tests in a row. Still some spikes in the CO readings, I am quite puzzled how to solve that. see the graphic: pberg0.home.xs4all.nl//pictures/large/test010908.gifIt's unclear however what the effect of the under air is. With softwood it's simple: light the small pile on top, leave the loading door slightly open and within 10 minutes from cold the roaring will sound. For one of the test runs I've been using wood briquettes, compressed sawdust and the like without an artificial binder. Without under air the combustion is quite slow, with the ash door open a 1/4" there is a world of difference. In short, it's encouraging but with a lot of work to be done. |

|

|

|

Post by chronictom on Sept 2, 2008 6:55:04 GMT -8

Maybe it's just me, but this seems to be turning more into a pathless masonry heater and away from a rocket stove.... no?

Don't get me wrong peter, it looks good and is the perfect size for what I want to do at the back of the house, just seems to be moving more and more to not being a rocket stove....

|

|

|

|

Post by peterberg on Sept 2, 2008 8:03:36 GMT -8

A pathless masonry stove! What a nice way to describe the thing. But it is not just you. In fact, it is a pathless stove. A bell system, to be precise. Only the combustion chamber is a rocketstove of some sort. The difference is here that the pyrolysis of the fuel is done in a different chamber. What the rocket-ish thing does is burning the wood gas resulting from the pyrolysis.

I seem to remember one of Donkey's projects doing such a thing. Wasn't that "Two-stage, Pyrolyzer-Rocket"?

|

|

|

|

Post by chronictom on Sept 2, 2008 8:39:12 GMT -8

I'll tell you what... you call it whatever you want, get the kinks worked out and I'll try building it in my own fashion afterward...  I like concept of it, especially for my 'furnace' system, although I think that I would look at putting steel tubes through the top of the bell to blow air through to pick up for a 'forced air' system. |

|

|

|

Post by martin on Sept 2, 2008 16:21:02 GMT -8

This design looks very interesting. It looks to me like it might be a good burn chamber and a good design for burning leaves, compressed in some form, or maybe reeds. Similar to fraigmites or bulrushes. The only drawback I could see is that a considerable amount of ash would move through the system, and it would have to be refueled more often, but I think your burner design could use this type of fuel. What would your thoughts be on this?

Martin

|

|

|

|

Post by Donkey on Sept 3, 2008 13:12:45 GMT -8

What can I say but WOW!! ??

wow..

Seems to me that most of any loose ash (perhaps all) would settle out in the first bell. Provide good access to that, air tight door or some such, problem licked.

This design does move things down the road from "Rocket Stove" somewhat. Dunnit??

I LOVE it!

|

|

|

|

Post by peterberg on Sept 3, 2008 13:17:38 GMT -8

In principle this combustion chamber could burn any woody stuff, provided the air can run through it. So for example you could bundle wood-like crop or compress it. A bundle of leaves clearly won't work. So you have to process the material before it is possible to burn it.

Ash wouldn't be a problem, because there are only two places where it will accumulate. One is the ash-pan under the grid, the other is around the chimney exit hole.

The bend in the rocket is no problem. First, there appears to accumulate no dust at all. The sloped sides of the bend will prevent it. And second, it is easy to reach the bottom of the bend by hand.

So, yes, it looks quite possible to use other types of fuel.

|

|

|

|

Post by Donkey on Sept 4, 2008 1:30:13 GMT -8

.. I think that if you make the ash door the same size or perhaps slightly (adjustable?) greater than your system size (6"), you could close the loading door tight and run completely with under-air.

I have a vaguely similar setup in my stove here at home and I'm mostly, quite happy with it. I do need to remember to close the under-air when opening my loading door though, or I get a little smoke into the room.

It seems to me though that your system may be less prone to that problem. Directing airflow to the front, up across the window first will help keep the stove glass cool and gasses moving in the right direction.

I'm curious... Your graphs appear exhibit a pulsing quality, though they are too short duration to be sure. If you run the stove for a good long time, say several hours. Do the spikes in emissions seem to fall into a regular pattern?

Also.. IF you change the volume of the bell, does the period of the pulse change?

I've seen some interesting patterns emerge in the adobe beehive bread ovens I've been making lately. Just wondering if some kind of parallels could be drawn.

|

|

|

|

Post by peterberg on Sept 4, 2008 10:49:30 GMT -8

Donkey, it's funny that you do mention it. At first, I've been using the thing with under air only. With a small plate behind the ash door to divert the majority of incoming air upward. That wasn't working satisfactorily, so I skipped the plate and opened both doors. Ash door a tiny gap, loading door as needed to get a healthy fire going.

Later on I've taken the bottom bricks out so the bottom was lowered an extra 2 inches. More room for fuel, larger fire. You've got me thinking about that again, and today I've reintroduced the steel plate thing. Worked better this time, probably because of the thicker layer of fuel. It's not easy to get the proportions right for under air and diverted upward. Anyway, it looks like over air should be 3 to 4 times as much as under air.

The ash door is nearly as large as the system, but isn't run fully open. When I do, the fire produces too much wood gas and the whole system chokes itself. With a very dirty burn as the result.

On the emission pulse side, spikes occur always at the point when the system is revving up. And at the end of a burn, when only coals are glowing, i.e. at the moment the flames are dying out. So, when I'm refilling too late, I've got two spikes on top of each other. Because in the glowing phase with the fresh fuel on top the fire produces an explosion of CO. But after some minutes, when the flames are dominant again, CO is going down together with O2 at the same time as the efficiency is going up. You can see this effect in the latest graph. Refill is at 36 minutes with a spike directly after that, and top efficiency at 39, coupled with CO and O2 at its lowest.

Whether or not the pulses go further apart with changing the volume of the bell, I don't know. This one has a more regular pattern, with the first spike earlier. But that could be due to the insulated heat riser I am using now. Within a couple of weeks we'll know whether a smaller bell changes the pulse again. Because around that time I'll rebuilding the thing, changing to a double bell.

Anyone tried refractory castable mixed with vermiculite? And at what proportions?

By the way, I've found a way to avoid the CO spike at the end. Refill a little bit, just before the flames are dying out altogether. It would be better though the system took care of that. My other design, from 2002, does. But that heater won't reach such absurd efficiency numbers.

|

|

|

|

Post by canyon on Sept 6, 2008 12:08:23 GMT -8

Thank you very much for continuing to share your experience with this! This is incredibly educational and inspirational!  |

|

|

|

Post by Donkey on Sept 6, 2008 20:03:09 GMT -8

Hmmm.

The advantage I'm seeing with the down-feed style woodbox is that the flame is held in a constant place. The fuel and the air are always at an optimum place for a clean burn.

I imagine that in your stove, the fire has room to meander about... Seek it's own path, as it were.. Does there tend to be unburned pieces laying about after things go out? Or does it pretty well burn everything, no fuss, no muss?

|

|