dvawolk

Full Member

DSR2 125mm open system (actual project)

DSR2 125mm open system (actual project)

Posts: 272

|

Post by dvawolk on Aug 21, 2024 2:18:03 GMT -8

Hello, I am having a problem with one detail in this construction... I am preparing for 160 mm system. And I calculated all the dimensions for it. Below is also the table where other dimensions are calculated - it might be of help for others... I have a question regarding air inlet... The air inlet for Shorty core equals 30% of chimney CSA. For 160 mm system size that gives 6032 square millimeters. 1.) Air intake should be rectangular for air intake in the door frame, right? For a rectangle that its sides are 1:3 I get (A)45 mm x (B)135 mm = 6075 square millimeters. 2.) The air that gets into door frame has to get out through the slits that are on left, right and upper side of door frame (C and D). I designed these slits like that: + 4 x "C" slits = 4 x 110 mm x 10 mm = 4400 square millimeters + 2 x "D" slits = 2 x 90 mm x 10 mm = 1800 square millimeters ----------------------------------------------------------------- CSA of slits in total 6200 square millimeters. Am I doing this right? Should air intake CSA bee the same on the outside of door frame (A x B)? Should air intake CSA be the same on the inside of door frame (all slits, 4C on sides and 2D above, combined)? For the door frame I used rectangular metal pipes 30 x 50 mm.  I hope I explained my questions clear enough. Dimensions for SHORTY CORE for other system sizes. See above images few posts back for easier understanding of it.  Have a nice day! |

|

|

|

Post by peterberg on Aug 22, 2024 8:34:25 GMT -8

The air inlet for Shorty core equals 30% of chimney CSA. For 160 mm system size that gives 6032 square millimeters. Correct so far. 1.) Air intake should be rectangular for air intake in the door frame, right? For a rectangle that its sides are 1:3 I get (A)45 mm x (B)135 mm = 6075 square millimeters. Correct again, go on! 2.) The air that gets into door frame has to get out through the slits that are on left, right and upper side of door frame (C and D). I designed these slits like that: + 4 x "C" slits = 4 x 110 mm x 10 mm = 4400 square millimeters + 2 x "D" slits = 2 x 90 mm x 10 mm = 1800 square millimeters ----------------------------------------------------------------- CSA of slits in total 6200 square millimeters. Am I doing this right? Should air intake CSA bee the same on the outside of door frame (A x B)? Should air intake CSA be the same on the inside of door frame (all slits, 4C on sides and 2D above, combined)? For the door frame I used rectangular metal pipes 30 x 50 mm. This isn't correct on ehrrmm... three points. Your drawing is not correct, the door posts should be as large as 30% of CSA of the chimney, together. So your rectangular pipes are waaaay too small. I used 60x40x2 mm air frame in my 130 mm development model, the inside of these is a little bit wider than 15% of CSA each. So you need to scale up to 55 mm square as the inside of these ducts. What you have now is about half of what is required. Second point is the position of the slits. All those should be situated in the top half of the firebox. So these slits need to be much wider. Moreover, the openings together need to be 50% of CSA, so the air that's enters the firebox won't be blowing in, just streaming calmly instead. This is a serious difference, believe me. Third point is the size of the frame. View the air frame itself as being flush with the inside of the firebox, all around. And then, place the U-profile on the bottom member, so this will act as a threshold to keep the ashes in. The door is not as high as the firebox as a consequence. The following might be understood already, I mention it just for good measure. This U-profile need to be open to the bottom member of the frame (obviously) but also to the door posts left and right. It will act as an air box, with the corners where the air is changing direction are much wider than the vertical posts. |

|

dvawolk

Full Member

DSR2 125mm open system (actual project)

DSR2 125mm open system (actual project)

Posts: 272

|

Post by dvawolk on Aug 22, 2024 11:10:48 GMT -8

Your drawing is not correct, the door posts should be as large as 30% of CSA of the chimney, together. Hi, peterberg. Oh, of course, stupid mistake... Thanks! I can get 60 x 60 mm square pipes with 2 mm wall thickness. This would give 56 x 56 mm =3136 square mm for one pipe, 6272 square mm for two pipes which is close enough to 30% chimney CSA. And as for the slits, 50% chimney CSA is 10053 square mm. I will be using 4 slits, each ~2513 square mm - each slit is 100 mm long and 25mm wide. Position of slits: two above and one on each side on the upper third of the height. As for the third point.. I like if the final door frame is flush with the firebox - it is sooo easy to sweep out the ashes... And i can add a removable threshold for easier cleaning AND still have ashes behind it? I remember that back ago you did use removable threshold with some other firebox model... The last part i understand, but thanks for reminding me, anyway. Will make a new sketch where the fixed details will be seen.. |

|

|

|

Post by peterberg on Aug 22, 2024 12:01:07 GMT -8

As for the ashes: I almost never clean it out completely. Just once in two weeks or more I scoop some out and that's it. Works better than a sqeaky clean firebox, the ashes will insulate a great deal. Tested that a couple of times and since then I am a lazy cleaner.

By the way: I honestly don't know what the effect would be of an air box that isn't partly exposed to the heat of the fire. I can imagine it could be a negative point.

The position of the side slits should be exactly what I said: the upper half of the firebox. The slit shouldn't start any higher, it took me a month to work that one out. So the upper third isn't good enough, tried that too by the way.

|

|

dvawolk

Full Member

DSR2 125mm open system (actual project)

DSR2 125mm open system (actual project)

Posts: 272

|

Post by dvawolk on Aug 22, 2024 13:23:56 GMT -8

... it came to my mind - hope I didn't hijack the thread for my personal projects... Maybe the details around the door frame are still useful here, but for the bell sketches it might be better to start a new thread... So here are the fixes of the door frame. System: 160 mmAir inlet in front of the door 6032 square mm (30% chimney CSA) Air intake inside the firebox coming through the slits in upper half of the firebox (combined CSA of slits = 50% chimney CSA, for 160 mm system this is 10053 square mm) -All the slits are 20 mm wide. Combined length of slits is 501mm.  There is another thing I would like to be checked... Looking from the top of opened "heat riser". The upper width and length is 231 x 231 mm which is exact calculation, too. But the lower part is not exactly 160 x 160 mm. The thickness of firebricks is 65 mm and the length of the port is 115 mm. Consequentially I had to add 50 mm thick insulation/brick there. The side insulation is 40 mm thick. In this way I get 181 mm length and 141 mm width of the bottom part of heat riser. The CSA here is the same (160 x 160 = 25600 vs. 141 x 181 = 25521) but it is not rectangular... Would this be inside of the specs? If not, then i will have to manage the port thickness in a more complicated way, but it will be still doable.  |

|

dvawolk

Full Member

DSR2 125mm open system (actual project)

DSR2 125mm open system (actual project)

Posts: 272

|

Post by dvawolk on Aug 23, 2024 23:31:01 GMT -8

There is another question. Say if I want to make a bell as narrow as outside of heating core, which is about 360 mm, the exhaust can flow in the sketched direction to get to the "real bell dimensions". The gap above the heat riser to the ceiling of the bell is only 115 mm (pink line), which gives CSA of 41400 mm. This is 200% of chimney CSA. I understand that this part will not work as a real bell, but I hope it would not cause much friction. Would it?  Chimney is insulated stainless steel, 200 mm diameter, over 7 meters high. |

|

|

|

Post by peterberg on Aug 24, 2024 1:44:07 GMT -8

There is another thing I would like to be checked... Looking from the top of opened "heat riser". The upper width and length is 231 x 231 mm which is exact calculation, too. But the lower part is not exactly 160 x 160 mm. The thickness of firebricks is 65 mm and the length of the port is 115 mm. Consequentially I had to add 50 mm thick insulation/brick there. The side insulation is 40 mm thick. In this way I get 181 mm length and 141 mm width of the bottom part of heat riser. The CSA here is the same (160 x 160 = 25600 vs. 141 x 181 = 25521) but it is not rectangular... Would this be inside of the specs? If not, then i will have to manage the port thickness in a more complicated way, but it will be still doable. Sorry, the above isn't within specs. Of course a little bit off specs wouldn't hurt anything, except... the rectangle is in the wrong direction. Depth should be smaller than width in order to work well for the double vortex. Found that out a long time ago, in 2012, during the early batchrocket development stage. For a heater that isn't an experiment, I would prefer hard firebrick for the lining. In order to stay as close to specs as possible, you could choose to use strips of 65 mm high, the thickness of the bricks for the liner. It's just what it says it is, a liner, not a construction part. |

|

|

|

Post by peterberg on Aug 24, 2024 2:14:09 GMT -8

There is another question. Say if I want to make a bell as narrow as outside of heating core, which is about 360 mm, the exhaust can flow in the sketched direction to get to the "real bell dimensions". The gap above the heat riser to the ceiling of the bell is only 115 mm (pink line), which gives CSA of 41400 mm. This is 200% of chimney CSA. I understand that this part will not work as a real bell, but I hope it would not cause much friction. Would it? Chimney is insulated stainless steel, 200 mm diameter, over 7 meters high. Hmmm... I my view, too much friction. Not so much for the space but more so for the forced 180 degrees change in direction immediatly after leaving the core. What about this idea: turn the core 90 degrees in horizontal plane so that its door is at the longer side of the bell. Build it as a left hand sidewinder and it will vent in the right direction as it is. Regarding depth of the bell: this will be about 100 mm more than what you mentioned above. Best to have a bypass while using this core, it won't start easily on its own while cold. The sidewinder version works as hoped for, I did the workshop conduction of a 150 mm one in the north of the Netherlands, in July. No space at all above the core as well, even the top of the riser box was left out and replaced by a ceramic glass cooking plate. There might be a heater workshop similar to the above idea about an hour away from my home, so I am very interested what the results of your project would be. I'd think this development deserves its own thread by now. Any suggestions for a title? |

|

dvawolk

Full Member

DSR2 125mm open system (actual project)

DSR2 125mm open system (actual project)

Posts: 272

|

Post by dvawolk on Aug 24, 2024 4:10:00 GMT -8

Okay, the new thread can be something like that: Project: Shorty Batch Box, 160mm system + brick bell. Or whatever you see fit search wise...

Okay, i can make it square to specs...

But since you mentioned bypass.. I have chimney intake pretty low: the center of chimney pipe is located 45-50 cm above the ground of the stove. Maybe it is better to check if the Shorty is smart decision or not for my implementation.

To use the bypass, would it be adequate to "isolate" part of the bell ISA, so that I would start with an ISA that is, say 1,3 square meters less (4,4 square meters instead of 5,7 square meters?). How much less ISA would you mark as a safe enough bypass for the Shorty core (sidewinder or not)? I am not able to make a direct bypass. I can only "isolate" parts of the ISA..

|

|

|

|

Post by peterberg on Aug 24, 2024 6:26:15 GMT -8

I have chimney intake pretty low: the center of chimney pipe is located 45-50 cm above the ground of the stove. Maybe it is better to check if the Shorty is smart decision or not for my implementation. What do you mean by çenter of chimney pipe is located 45-50 cm above ground'? I would regard that as quite high, the more since the entire heater is low. Could you draw a sketch to illustrate that? My opinion: nothing aganst the Shorty which is helped by the 200 mm insulated chimney you have there. To use the bypass, would it be adequate to "isolate" part of the bell ISA, so that I would start with an ISA that is, say 1,3 square meters less (4,4 square meters instead of 5,7 square meters?). How much less ISA would you mark as a safe enough bypass for the Shorty core (sidewinder or not)? I am not able to make a direct bypass. I can only "isolate" parts of the ISA.. Isolating part of the bell is new to me, how would you do that? That 1.3 m² is 22.8% of the total ISA, might well be enough. |

|

dvawolk

Full Member

DSR2 125mm open system (actual project)

DSR2 125mm open system (actual project)

Posts: 272

|

Post by dvawolk on Aug 24, 2024 7:27:34 GMT -8

Thank, Peter form moving the posts to new thread... I wass reffering to chimney connection on the chimney pipe. I can couple the heater to chimney pipe at ~45cm height.. and this is also connected to "bypass system" that i will be able to use, see below.  As for the isolating the bell... I don't know if it is called like that, see sketch below.  This is very simplified sketch, but should be representative. On the left the hot exhaust gasses need to come below the blue constriction so that they can enter the chimney. On the right, the constriction is removed (rotated, pulled etc.) and gasses will "bypass" the lower part of the bell ISA, consequentially entering the chimney hotter than before... If my chimney pipe would coupled higher up, then i could bypass even more of the bell ISA. Don't know if isolation is a good word, what i meant is: to make part of the bell's ISA not accessible to hot gasses. |

|

|

|

Post by peterberg on Aug 24, 2024 8:27:19 GMT -8

Looks good to me. That valve can be done in a number of ways, you'll work one out no doubt. Isolation is not a good word, bypassing part of the bell might be better.

|

|

dvawolk

Full Member

DSR2 125mm open system (actual project)

DSR2 125mm open system (actual project)

Posts: 272

|

Post by dvawolk on Sept 8, 2024 22:20:31 GMT -8

...So we were slightly changing the future appearance of our house and thatswhy there was no update... I am weighting options of Shorty sidewinder it might really come as a better solution to get less restricted gas flow to bell... If I turn the heatriser from the original Shorty batchbox counterclockwise, what option below would be correct? Totally on the right is the original tloris of shorty. A represents turning of the heatriser where the firebox is extended for the orange part of the wall which used to be the left part of the backwall by the port. B represents turning of the heatriser where the firebox is not extended at all - the port starts directly at the original end of firebox - this is also the end of the slopes so I would say this is not the correct way. C reprenents turning of the heatriser where the firebox is slightly extended for an X dimension. I would say that the last option will be correct, the X being something between options A and B, maybe the same as the width of the port?  |

|

|

|

Post by peterberg on Sept 9, 2024 1:10:20 GMT -8

Neither of these seems to be entirely correct. The only one Shorty sidewinder that has been built to date is the one in Groningen, in July. This one sports an extended firebox, just because the fuel length dictated that. So the firebox' depth is 5B instead of 4B, but the shorter one will work just the same. It looks like your option B is the closest though the extension has nothing to do with the placement of the port or whatever. It's just extended at the front side, as it were. Here's a picture of the extended core drawing. It's a right hand sidewinder but that's just a mirrored one to what you are planning.  And a link to the sidewinder core drawing in skp8 format. Go to pberg0.home.xs4all.nl/pictures/dev2023-2024/Sidewinder/ and choose Shorty150 sidewinder core. |

|

dvawolk

Full Member

DSR2 125mm open system (actual project)

DSR2 125mm open system (actual project)

Posts: 272

|

Post by dvawolk on Sept 12, 2024 8:38:47 GMT -8

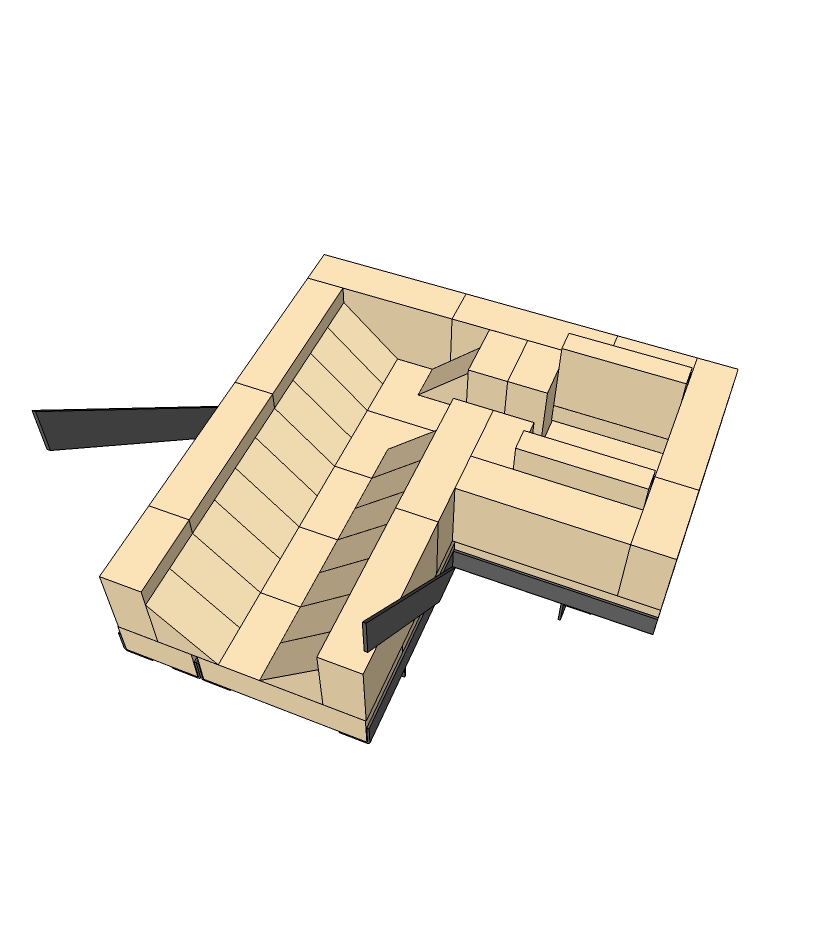

Thanks for clarification. It seems that sidewinder really is the best option for my case... I made a sketchup version for 160mm Shorty Sidewinder. I added a bypass which takes away just over 1,4 square meters (when bypass not in use, the stove has 5,7 square meters of ISA and when bypass is used, it is 4,3 square meters). Those bypass elements are translucent for clarification reasons - otherwise these will be made from metal. On the following link there is a SketchUp file that i saved in version 8 format. Hope it will work. drive.google.com/file/d/1U7RR0UCK4Gr9J3vQRZsK5ep63ezfptjH/view?usp=sharingBelow are also the pictures of Section Cuts in SketchUp when bypass is in use and when it is not. As far as i understand, it should work :-)..     The feedback would be much appreciated. |

|