8”/200mm Batchbox detailed drawings

Nov 13, 2021 9:11:29 GMT -8

Orange, martyn, and 3 more like this

Post by fiedia on Nov 13, 2021 9:11:29 GMT -8

This RMH will heat three bells. The hole project is here.

This thread gives detailed drawings for the batchbox and the first bell. Bell2 & 3 will be built once bell1 works as expected.

Bell1 + box overview:

Same with skin2 bricks removed (firebiricks in red, standard bricks in orange):

removing front skin1 bricks:

Hot smokes will spread in the large space on top of bell1. As it cools down, it will go down and enter the internal chimney at the back of the bell and then exit through the top flue.

Two pipes are in place for the next extension. They will remain blocked until I build bell2.

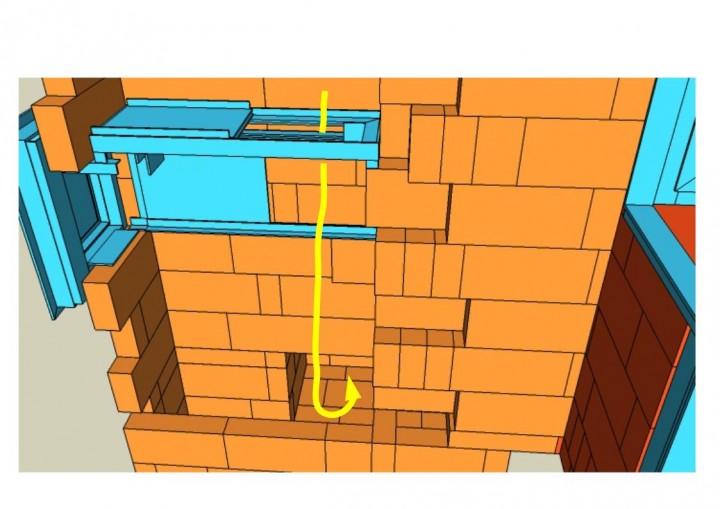

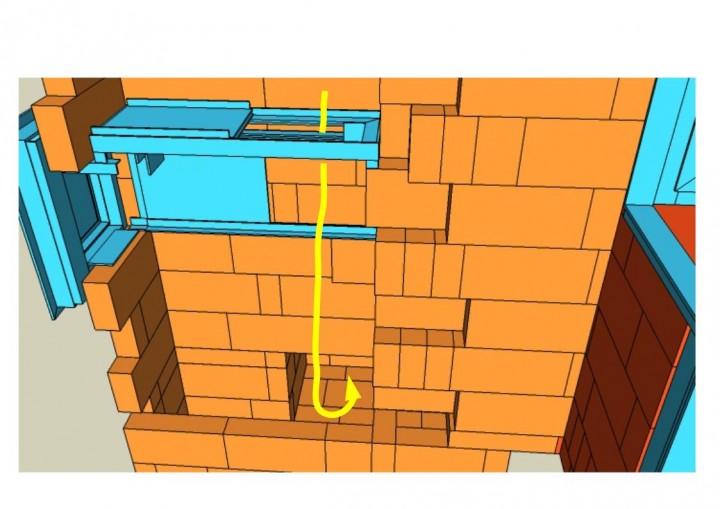

Firebox bypass:

On my former batch box, the port was lower than the box ceiling, smokes escaped from the front door every time it was opened. On this design, there will be a bypass to shunt the heat riser thanks to an internal chimney at the back of the firebox. The opening being at the top of the firebox, less smoke should leak from the front door.

Flue bypass:

The flue bypass uses two sliding doors which combinations offer three possibilities:

- position 1: normal position to heat bell1 and 2. Smokes have to go down thru bell1front, then rise through the internal chimney at the back before reaching the flue

- position 2: when starting a fire. Smokes go directly to the flue, reducing dirty smoke deposit and condensates in the whole bell

- position 3: after the burn, when the glowing ember phase starts. The doors close the top of bell1, limiting heat loss thru the flue.

balancing bell1 and 2:

If everything goes well, the 200mm batchbox will be powerful enough to heat up bell1 and bell2. Since my last experiment, chaining two bells, was quite deceiving, I added doors which would balance the smoke flow between bell 1 and 2.

An important point here: the two bells will be linked thanks 2 200mm pipes at the top and bottom. Smokes entering bell2 should reach 400 to 500 °C. It should work better than chaining bells in series (bottom of bell1 linked with top of bell2). In my last prototype, smokes coming from the bottom of bell1 remained below 200°C. They were not hot enough to heat up bell2.

Two sliding doors can block gradually the flow going through bell 1 and 2. In the following setup, both doors let smokes flow through both bells:

![]()

In this second setup, smokes will flow exclusively through bell1:

In this third setup, smokes will have to flow through bell2 before reaching the lower part of bell1:

A latch (one plate on each door) maintains a minimum opening at any door positions (opening ranges from 0.75 to 1.75 HR CSA).

Ashtray:

The sidewinders design leaves some unused space behind the floor channel. I added an ashtray in the back of the firebox.

HR:

It is better to have a round shape insulated heat riser. This riser will be made of insulating light firebricks. I cut the bricks according to batchrocket.eu/fr/plans to get an octagonal base.

The light refractory HR bricks will be coated with a siicate sealent according to Forsythe and Yasin advises : donkey32.proboards.com/thread/3676/disintegration-superwool-ceramic-fibre-board?page=2.

Gaps between HR and bell bricks will be filled with vermiculite and clay mix.

Thermal mass:

Thermal mass is improved by doubling brick walls and filling any empty space not available for hot smokes. I will use a mix of clay and stones.

Thicker walls take much longer to get warm. They are preferably built on the back of the bell.

maintenance:

Steel degrades faster inside a hot and moist environment. Every steel component have been designed to be removable in case they need to be fixed or replaced. 3 doors on the bell sides give access for bypass removal and sweeping.

I plan to insert several thermocouples to monitor temperature profiles:

Full sketchup file is available here

Skin1 dry mounting in the workshop:

HR:

firebox base:

bottom:

middle:

This thread gives detailed drawings for the batchbox and the first bell. Bell2 & 3 will be built once bell1 works as expected.

Bell1 + box overview:

Same with skin2 bricks removed (firebiricks in red, standard bricks in orange):

removing front skin1 bricks:

Hot smokes will spread in the large space on top of bell1. As it cools down, it will go down and enter the internal chimney at the back of the bell and then exit through the top flue.

Two pipes are in place for the next extension. They will remain blocked until I build bell2.

Firebox bypass:

On my former batch box, the port was lower than the box ceiling, smokes escaped from the front door every time it was opened. On this design, there will be a bypass to shunt the heat riser thanks to an internal chimney at the back of the firebox. The opening being at the top of the firebox, less smoke should leak from the front door.

During normal operation, smokes have to go through the heat riser. The internal chimney will be closed by a sliding door (firebox bypass).

Flue bypass:

The flue bypass uses two sliding doors which combinations offer three possibilities:

- position 1: normal position to heat bell1 and 2. Smokes have to go down thru bell1front, then rise through the internal chimney at the back before reaching the flue

- position 2: when starting a fire. Smokes go directly to the flue, reducing dirty smoke deposit and condensates in the whole bell

- position 3: after the burn, when the glowing ember phase starts. The doors close the top of bell1, limiting heat loss thru the flue.

balancing bell1 and 2:

If everything goes well, the 200mm batchbox will be powerful enough to heat up bell1 and bell2. Since my last experiment, chaining two bells, was quite deceiving, I added doors which would balance the smoke flow between bell 1 and 2.

An important point here: the two bells will be linked thanks 2 200mm pipes at the top and bottom. Smokes entering bell2 should reach 400 to 500 °C. It should work better than chaining bells in series (bottom of bell1 linked with top of bell2). In my last prototype, smokes coming from the bottom of bell1 remained below 200°C. They were not hot enough to heat up bell2.

Two sliding doors can block gradually the flow going through bell 1 and 2. In the following setup, both doors let smokes flow through both bells:

In this second setup, smokes will flow exclusively through bell1:

In this third setup, smokes will have to flow through bell2 before reaching the lower part of bell1:

A latch (one plate on each door) maintains a minimum opening at any door positions (opening ranges from 0.75 to 1.75 HR CSA).

Ashtray:

The sidewinders design leaves some unused space behind the floor channel. I added an ashtray in the back of the firebox.

HR:

It is better to have a round shape insulated heat riser. This riser will be made of insulating light firebricks. I cut the bricks according to batchrocket.eu/fr/plans to get an octagonal base.

The light refractory HR bricks will be coated with a siicate sealent according to Forsythe and Yasin advises : donkey32.proboards.com/thread/3676/disintegration-superwool-ceramic-fibre-board?page=2.

Gaps between HR and bell bricks will be filled with vermiculite and clay mix.

Thermal mass:

Thermal mass is improved by doubling brick walls and filling any empty space not available for hot smokes. I will use a mix of clay and stones.

Thicker walls take much longer to get warm. They are preferably built on the back of the bell.

maintenance:

Steel degrades faster inside a hot and moist environment. Every steel component have been designed to be removable in case they need to be fixed or replaced. 3 doors on the bell sides give access for bypass removal and sweeping.

I plan to insert several thermocouples to monitor temperature profiles:

Full sketchup file is available here

Detailed jpg drawings here.

Skin1 dry mounting in the workshop:

HR:

firebox base:

bottom:

middle:

top: