|

|

Post by Solomon on Feb 3, 2021 17:52:53 GMT -8

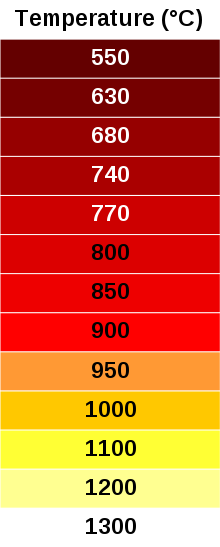

I ordered a heavy duty furnace thermocouple to try to stick in my 8" RMH core. Not entirely sure where to stick it. The probe length is about 6.5" long and can be trimmed. One option I thought of was to screw it into the side of the burn chamber somewhere. The length could put the sensor right in the fire path. I could put it just about anywhere as my core and riser are 2" thick ceramic fiber. The problem comes with the connecting wiring. It can only handle 750 degrees and so that limits it pretty much to the bottom of the barrel to be any kind of safe. I'm led to believe temps down there should be in the 300F range. Perhaps I could stick it in the back wall of the core or riser where the flame splashes against the back wall before travelling up the riser? I'm looking for the hottest possible spot. If a J tube core can make 2300+ temperatures, I'll happily sacrifice the thermocouple to find out. First experiment, I just tested it with my soldering torch with MAP gas (which should be capable of 2000C). I read max of over 2000F and over 1300C, which doesn't make any sense because that's not the same temperature. Or maybe I misread it. My MicroSD card took a crap, so I lost the video. But according to the color chart, I would say the 2000F (1093C) is more or less accurate.  Was glowing bright orange. The sensor itself seems like it was fine. One of the ceramic insulators cracked on reheat. Thermal shock I don't think is possible in a RMH. Anyway, how do you think I should mount it? Any other ideas? How much should it stick through? Let's burn this thing up. |

|

|

|

Post by josephcrawley on Feb 3, 2021 18:34:22 GMT -8

Pottery supply places sell a ceramic tube that fits over the end of those thermocouples. It is supposed to help with their longevity.

|

|

|

|

Post by Solomon on Feb 3, 2021 20:28:28 GMT -8

It came with its own ceramic insulation. Came with 6. I still have 5.

|

|

|

|

Post by pigbuttons on Feb 6, 2021 19:03:17 GMT -8

I would vote for a point in the riser about six inches above the top of the burn tunnel. On a fast burn that is about where the flames should taper off and probably where the temps should be highest, at least if you accept the theory that while there is still combustion going on the air temp continues to build upon itself. Second would be at the top edge of the burn tunnel just where it intersects the riser because of the turbulence and the fact that it has been traveling horizontally and finally gets to turn vertical.

Since the diameter of the thermocouple is rather small I don't know that it matters how far it protrudes, but just from thinking about it I'd want the tip to be centered in the gas flow.

One last thought is that if it picks up radiant heat as well, it might be placed just past the burn tunnel entrance from the feed tube since the coal bed radiation has to be another hot spot.

|

|

|

|

Post by Solomon on Feb 6, 2021 21:24:18 GMT -8

Good ideas.

Ernie and Erica and Paul were talking about using cones and putting little shelves at intervals up the riser. Maybe I could do that with thermocouples.

Has nobody ever done this? On one hand I'm a little flabbergasted at how little in depth research has been done, but on the other, I kind of understand. RMHs are a poverty level heating appliance. They are advertised as being able to be built for $100. Furthermore, you can't get better than 100%, and the existing units are about as close as you can get to that anyway, so realistically, there's no motivation to make them more efficient, only to make them easier to use, which Peter Van Den Berg has been working on for years already.

Anyway, thermocouples don't cost that much. The normal ones which still handle 1000 degrees are less than or much less than $15. The one I'm using cost like $35.

Oh, I've just had another idea, a reburn port. An EGR, if you will.

Anyway, I still want to play with an oxygen sensor. Maybe it could control a small secondary air valve to give a little extra air if running rich, prevent black smoke even more.

|

|

fuegos

Full Member

not out of the woods yet

not out of the woods yet

Posts: 177

|

Post by fuegos on Feb 8, 2021 12:42:09 GMT -8

"Has nobody ever done this? On one hand I'm a little flabbergasted at how little in depth research has been done, but on the other, I kind of understand. RMHs are a poverty level heating appliance. They are advertised as being able to be built for $100. Furthermore, you can't get better than 100%, and the existing units are about as close as you can get to that anyway, so realistically, there's no motivation to make them more efficient, only to make them easier to use, which Peter Van Den Berg has been working on for years already."

Peter ,Matt , Vortex Satamax & many others have done 1000s of hours of well documented research backed up with exhaust gas analysis and so have come up with a number of designs that are proven to work efficiently with low emissions.

Windmills , olive presses & charcoal forges are all "poverty level " technology .Much of what we consider to be superior technology is socially useless & only makes sense in the pursuit of profit.The low cost of RMH tech has lowered the entry level and the fact that we can freely share what we know has also helped the advancement .

|

|

|

|

Post by Solomon on Feb 8, 2021 17:42:46 GMT -8

Yes, I know all this. But these guys have Testos, they've done exhaust gas analysis. Nobody that I've seen has put a thermocouple in a heat riser. I would love to be proven wrong. But I just haven't seen it. I've never been able to find anybody's documentation on exactly how hot their core got.

Yet videos are out there with Ernie Wisner pontificating about how he might be getting over 3000 degrees which is without evidence and surely impossible.

They are efficient. Yes. That's the point. They can't get more efficient! They can get smoother and easier to use and with fewer burps and hiccups.

|

|

|

|

Post by martyn on Feb 9, 2021 1:10:28 GMT -8

Hi Solomon, It would be great to have more detailed scientific information and documented facts relating the best possible dimensions and temperature ratings but rocket stoves can only relate to a miniscule percentage of worldwide home heating and cooking.

We have this forum where a handful of dedicated hobbyists offer thier opinions and home findings, a few other English speaking sub forums where you can find similar information and we have Facebook where in amongst the many misleading and inaccurate post there are also a few very knowable people!

If a large investment company, who could employ scientist and physicist with a few million $ budget, took an interest them we might get all the information we all seek!

It seems to me that we, as enthusiast are very far and few between.

The majority of builders appear pleased to use the most basic materials and concepts and be content with the end result.

Personally, I am very grateful for the dedicated few who have openly shared thier findings but of course I would love to know more.

There does seem to be more development and concepts being tried out especially in the colder counties like Russia and Polland but it is difficult to follow via translators and I have witnessed how these people are often disregarded by English speaking forums!

I look forward to your temperature findings, I would love to know exactly what we can expect inside the hottest areas ?

|

|

serg247

Junior Member

The mountain can not be conquered, it can allow it to ascend...

The mountain can not be conquered, it can allow it to ascend...

Posts: 111

|

Post by serg247 on Feb 9, 2021 1:49:15 GMT -8

|

|

|

|

Post by peterberg on Feb 9, 2021 3:11:33 GMT -8

Nobody that I've seen has put a thermocouple in a heat riser. I would love to be proven wrong. But I just haven't seen it. I've never been able to find anybody's documentation on exactly how hot their core got. Always nice to pleasure someone, yes, you've got that wrong. Back in 2012, during development of the batch box rocket I bought a cheapish dual channel digital thermometer and two K-type thermocouples good for 1000ºC (1830ºF). At the time I assumed the highest temperatures would be reached inside the riser. I installed one sensor right above and in the centre of the heat riser and one through a small hole at the back, sticking one inch inside, roughly halfway the height of the port. Long story short, the top thermocouple registered repeatedly 900ºC (1650ºF) without much difficulty. The core had to be pushed hard of course, but in general two full loads (13 lbs per load) of softwood species back to back were sufficient. The lower positioned thermocouple is another story: it died quietly during the second test run, registering 1080ºC (1980ºF) while doing that. Later that year I was able to borrow a higher specced digital thermometer and two thermocouples from a guy in France. This set was specced up to 1300ºC (2370ºF) while in theory the limit for atmospherically aspirated wood burners (without the help of a blower) would be 1200ºC (2190ºF). It turned out in normal use that simple core could reach 1100ºC (2010ºF) just like that. When pushed hard the highest I ever measured was 1173ºC (2140ºF), very close to the theoretically maximum, I was led to believe. After six weeks I had to return the thermometer set, but in the mean time I tried several other locations at the back of the heat riser. Higher up mostly, because it turned out the highest temperature spot shifted up during the top of the burn and came down again when the end of the burn came in sight. A lot of numbers, I admit that. I'd think all this is somewhere on this forum but delving into my notes was easier. |

|

|

|

Post by Solomon on Feb 9, 2021 14:56:27 GMT -8

Thanks Peter. That's exactly what I was looking for. I'm happy to be shown that which I haven't seen.

I'm an engineer. I'm all about numbers. It's not science without numbers.

Your numbers make a lot of sense. Some of the [speculated] numbers I've seen and heard do not make any sense at all, like 3000+ degrees F.

I'm going to want to play with this a bit more. Building an 8" CFB core now, later a 6" CFB core, then perhaps play with the cast dragon core.

|

|

|

|

Post by gadget on Feb 9, 2021 20:45:40 GMT -8

Current Guinness world record for wood fired kiln is 2845F set in 2016 by Lin Jui-Hwa. I think with a very well turned and insulated RMH you could reach 3000F right at the roof of the tunnel where the bricks like to glow. Not uncommon to get a very bright orange glow right there. I think thats the hottest part of a rocket mass heater and probably a great location for you to melt that probe. I would start there.

Forced induced wood fires can get pretty dang hot. Shot, I've had damn near white/yellow steel on my heater before and yes it melted the edge pretty good where a small piece of insulation was missing in one firing.

Coal (second stage of wood fires) burns at a little over 3500F, so that should be your maximum with a near perfect air volume and enough insulation.

|

|

|

|

Post by Solomon on Feb 19, 2021 21:21:49 GMT -8

Update:

Tested the core the other day. Thermocouple was 6 inches up the riser. It displayed 2446 degrees before reading "-----". Happened at least twice that I was watching. At the time it quit reading, it was rising at 2-3 degrees every half second. I have it on video.

Thermocouple survived.

The interior layer of ceramic fiber board seems to have gotten a bit cooked, maybe over cooked.

Riser cracked on the inside.

So, unless somebody has documented something I haven't seen (an obvious possibility) I'm claiming the record.

|

|