|

|

Post by Solomon on Jan 28, 2021 15:24:33 GMT -8

Coincidentally, I calculated the Wisners pipe length and compared it to Berg's numbers. 101 SF of bell equals 48 feet of 8" pipe, so remarkably consistent. But I believe more is predicated on the chimney, of which I have a very tall straight one. Just need the right temperature to get to the chimney.

The compressed air idea is just a jet pointed up the chimney on the inside. Venturi effect will induce flow in the direction of the jet. No mucking about with lighting fires in weird places, just reach over and turn a valve and instant draw. When the fire is burning, turn it off (will have to learn what conditions allow it.

For me, sticking fire in the chimney was never going to do. Solution was always going to be mechanical.

I'm planning on cleanouts through the manifold, 10" port, then at the end of the bench. Possibly also in the corner.

|

|

|

|

Post by pigbuttons on Jan 28, 2021 18:57:39 GMT -8

I thought that might be what you were talking about with the compressed air. I've never heard, read, or seen, it done, so you are going to have to name it. How about the "Solomon CA (for compressed air) Venturi." SCAV (as in scavenger) for short.

You are absolutely correct on the straight chimney being a big advantage. Once the air flow has started to cool turns are harder to make and turbulence eats up the velocity.

Interesting how two separate designs by two different designers arrive at such close solutions. It happens all the time in science, one of those things that make you go "hummm?"

|

|

|

|

Post by Solomon on Jan 29, 2021 7:49:51 GMT -8

DIS, Draft Induction by Solomon SAID, Solomon's Air Induction Draft SID, Solomon's Induction Draft Solomon Compressed Air Venturi works, though a venturi generally required a constriction in the pipe. SCAV SID, Solomon's Instant Draft DID, Dirtling Induction Draft (Dirtling is my Channel, If Donkey can be Donkey, I can be Dirtling, right?) DCAD, Dirtling Compressed Air Draft DMFDI, Dirtling Motive Flow Draft Inducer (I think this one is the most technically correct so far)  |

|

|

|

Post by Solomon on Jan 29, 2021 8:05:01 GMT -8

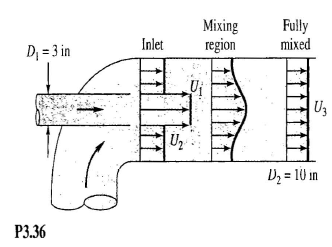

Here's perhaps a better diagram for our purposes media.cheggcdn.com/study/744/744ddae9-2521-44a0-a32e-0151c787ff71/4762-3-36IP1.png It will be 1/4" piping because that's normal air hose standard, but I will play around with the nozzle size. I want the optimal induced flow without adjusting the valve, without over drafting, and without using a massive amount of compressed air. Intuitively, I don't think it will take much, maybe start at 1/16" orifice and go from there. |

|

|

|

Post by pigbuttons on Jan 29, 2021 19:26:22 GMT -8

SID, Solomon's Induction Draft,

Is what I like best, clean, simple, and easy to understand.

The diagrams help a lot. thanks.

|

|

|

|

Post by Solomon on Jan 29, 2021 21:09:23 GMT -8

Yeah, the bottom one especially. Except D1=1/16" and D2 =8"

Turn it 90 degrees counter clockwise and hook a split barrel on the inlet and you have a chimney.

I picked up my CFB and riser today. So I'm gonna need to make some decisions soon.

|

|