Mixb

New Member

Create DSR2 115mm for Garage

Create DSR2 115mm for Garage

Posts: 4

|

Post by Mixb on Jan 18, 2021 17:17:22 GMT -8

Piterberg, please give feedback on this issue. : Wondering that if 2 bells have the same isa, are made out of the same material and the same amount of heat is put into both of them, which one would be more efficient at extracting more heat, a tall tower bell or a short bench bell? Of course, the roof will be the hottest part of both bells and that the short bench bell has more surface area in its roof than the tower bell but it lacks the depth the tower bell has allowing more stratification to occur. So if a person doesn't have a lot of floor space to build a bell, the tower bell makes the most sense, but if less efficient, than how much taller, or more tower bells would be required to equal the same efficiency as the bench bell? I am also very interested in a rectangular metal cover for my similar to DSR2. |

|

|

|

Post by peterberg on Jan 20, 2021 1:36:12 GMT -8

Hi MixB, welcome to the boards.

Sorry to say, I've spotted a couple of mistakes in your build.

First, the stepping in of the rear wall to the port is wrong. That rear wall should be flat (20 mm chamfers in the corners excluded), as it is now the proper air streams will almost certainly disrupted. When you placed the rear wall bricks the other way around so the stepping in faced the riser there wouldn't be a problem. Stepping in of these bricks aren't necessary though, as long as the depth of the port isn't approaching twice the width you would be fine.

The overhead p-channel is wrong as well, in more than one way. To begin with, this core design is developed and tested using a floor channel as the secondary air source, a p-channel was ruled out in the very start of development. So you need to either implement a floor channel or no secondary air provision. In the latter case a half open door or 50% spark screen need to be used.

A p-channel for a straight or sidewinder batch box should be the same cross section area throughout. Plus the horizontal part should be on top of the firebox, out of the hot environment of the firebox.

As it is now, it isn't flush with the back wall, there are major leaks left and right because of the port's wall recess.

To conclude, the top box should be as wide as the firebox and be a square cross section. As you have drawn, it's as wide and high as the short riser which isn't wide enough to let the thing work properly. The ceramic blanklet or other insulative material should be in the short riser stub only, everything downstream need to be wider. In the development core, there's no insulation in the top box at all. The top box could be built out of insulative material though, when the right proportions are respected. Although it's tempting to think the riser is just bent over in a 90º corner, in real life this isn't sufficient to have it working well.

Sorry to say, this calls for a rebuild. Better to ask for feedback before commencing the build.

|

|

Mixb

New Member

Create DSR2 115mm for Garage

Create DSR2 115mm for Garage

Posts: 4

|

Post by Mixb on Jan 20, 2021 6:20:51 GMT -8

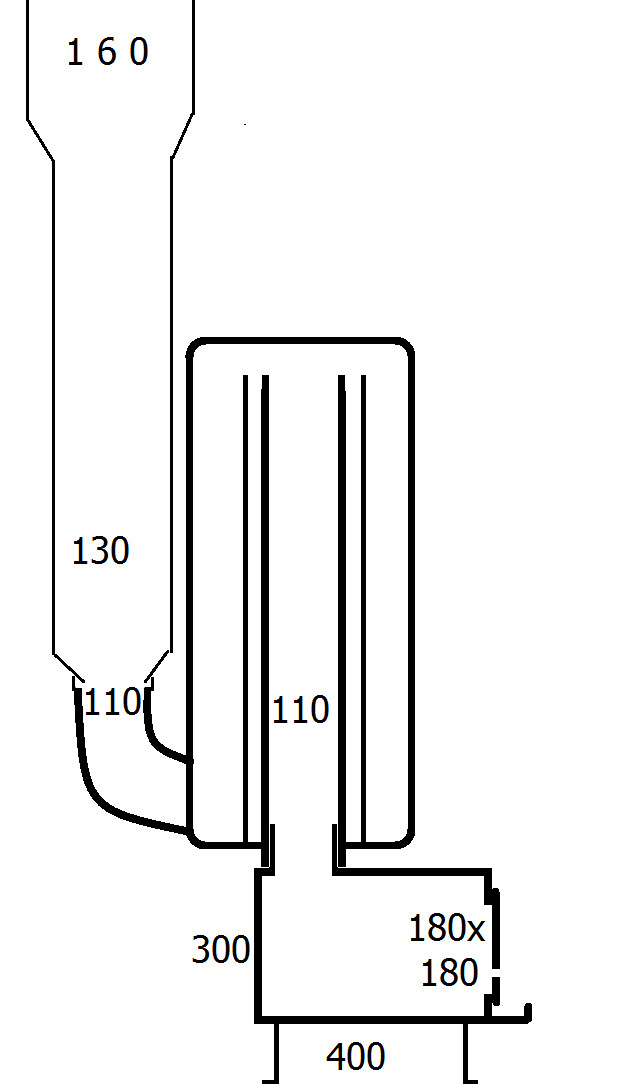

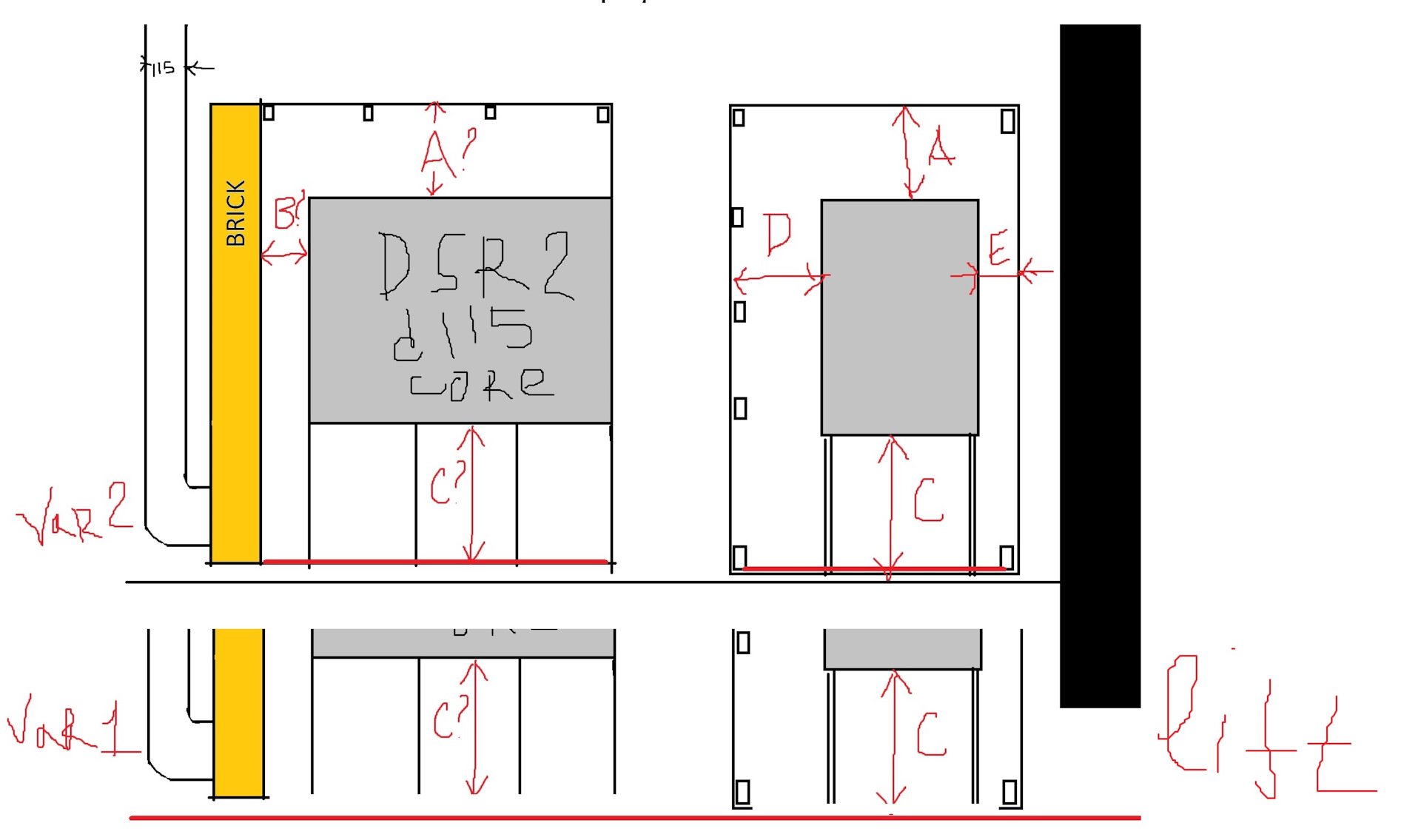

Hi MixB, welcome to the boards. ... Sorry to say, this calls for a rebuild. Better to ask for feedback before commencing the build. Thanks for answer. Even before reading your answer, I planned to redo my implementation, with the dimensions close to basic table. And I am very interested in the answer to the question of topic. Because in my garage, in location of stove, it is not possible to make 2 barrels in height. I plan to make Case like in picture bellow - rectangular made of metal 0.5 mm thickness. And my experience of using a Cap (Case) made of 1.8 mm metal from storage water heater says that for my garage, blowing with 2 fan's is more convenient than natural convection. Therefore, ISA can be much smaller.    I plan to lift core on metal stands. I have some questions. 1) Optimal distance between Case and Core (DSR2 - fireclay brick). Imho A = 300mm, B=70mm, C=200-300mm, D=70-100mm, E=50mm (between case and garage wall (IR insulated alluminium) ). 2) Is base insulation required (between garage floor and bottom Case)? Garage floor is 15cm of concrete. Under floor is a basement with 10cm of foamed polystyrene on top.  |

|

Mixb

New Member

Create DSR2 115mm for Garage

Create DSR2 115mm for Garage

Posts: 4

|

Post by Mixb on Jan 22, 2021 5:32:32 GMT -8

I found on local forum (rus, forumhouse.ru) photo of inside of rectangle Case (Cap, Bell) of stove (made viktrych ).  I am interested in feedback on this type of Case (Cap, Bell). What should I look for? |

|

|

|

Post by peterberg on Jan 23, 2021 3:04:38 GMT -8

1) Optimal distance between Case and Core (DSR2 - fireclay brick). Imho A = 300mm, B=70mm, C=200-300mm, D=70-100mm, E=50mm (between case and garage wall (IR insulated alluminium) ). The top A=300mm is optimal, all other distances aren't very important, one excluded: E=50mm. That is very small, better to have more, like 200 mm. Provided there's also an air cooled reflection screen on spacers so air is allowed to stream behind it. As far as heat shielding goes, this is the absolute top. Have a look at all the spaces around the core, in horizontal plane this cross section area should be 5 times the system size as minimum. Otherwise, it would pose a friction in the smoke path. 1)2) Is base insulation required (between garage floor and bottom Case)? Garage floor is 15cm of concrete. Under floor is a basement with 10cm of foamed polystyrene on top. For a bell system on a concrete floor no insulation is required, but you'll lose some heat there. In a bell construction the exhaust pipe should be well above the floor. Fine dust will settle on the floor in the bell and there's your insulation. |

|

Mixb

New Member

Create DSR2 115mm for Garage

Create DSR2 115mm for Garage

Posts: 4

|

Post by Mixb on Jan 31, 2021 2:25:18 GMT -8

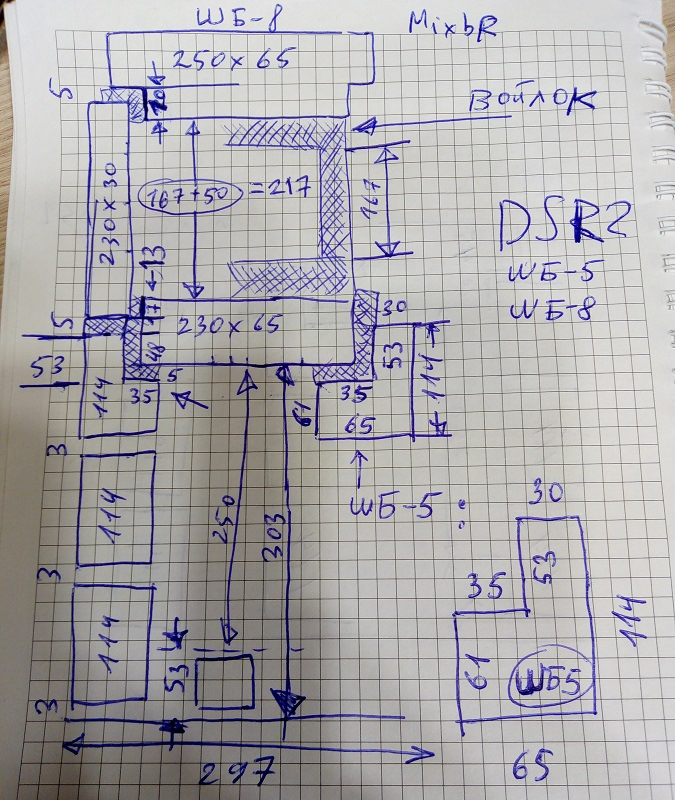

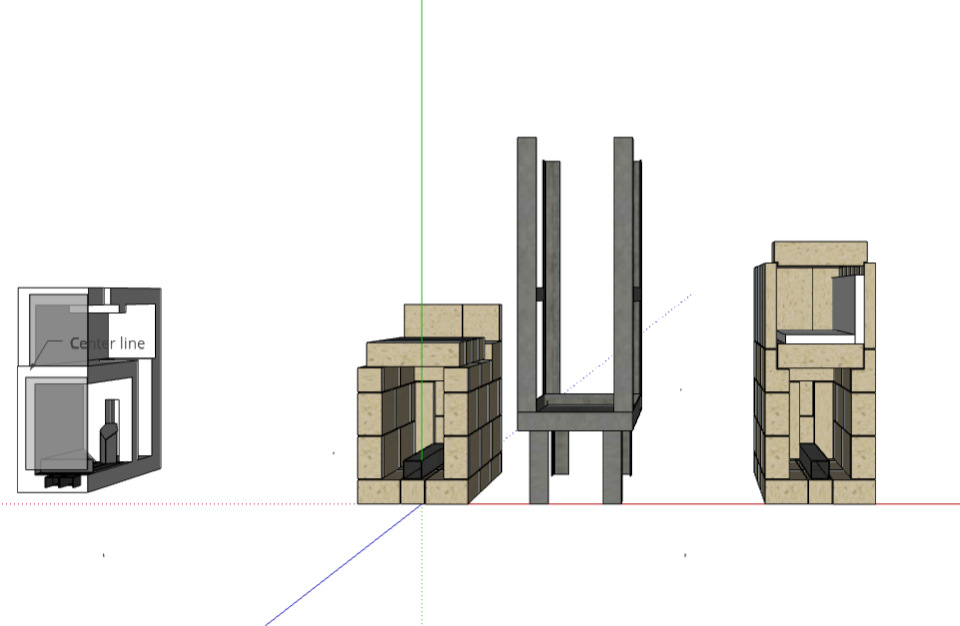

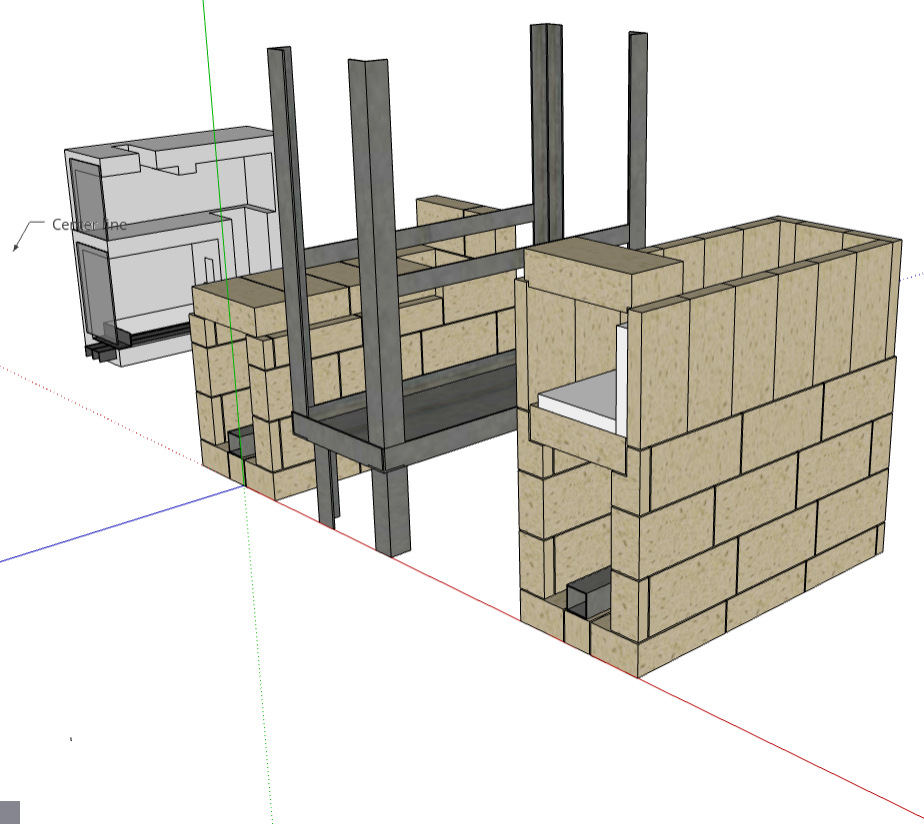

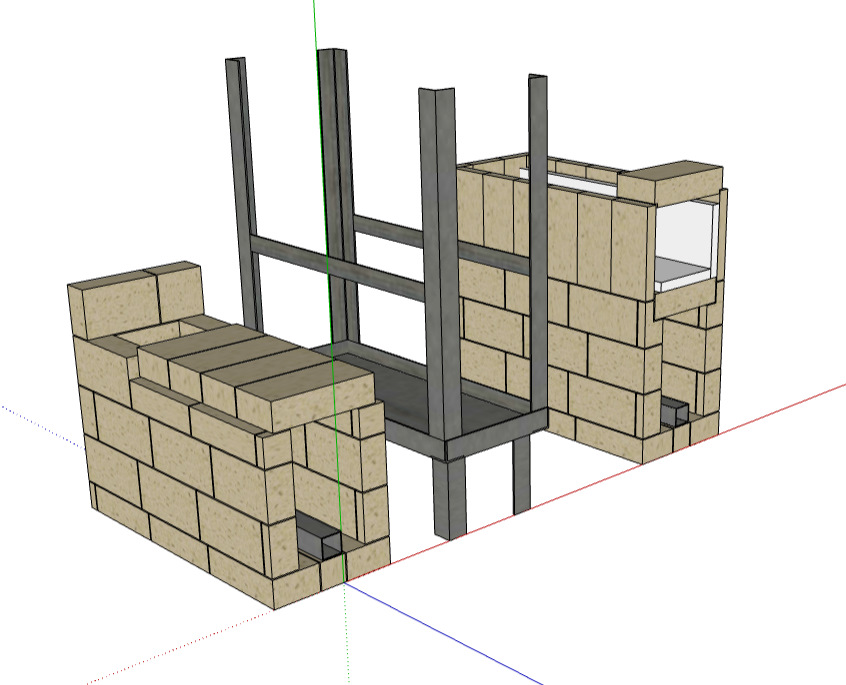

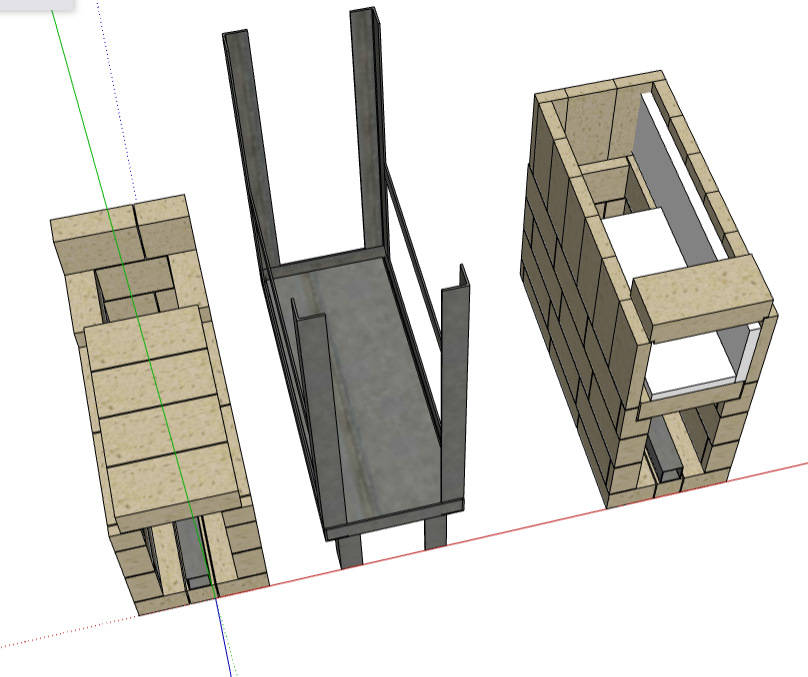

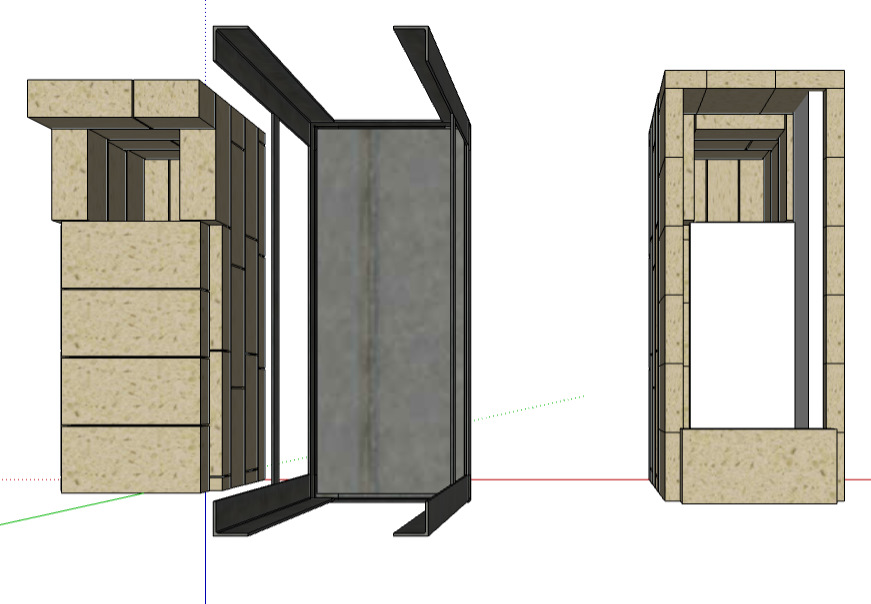

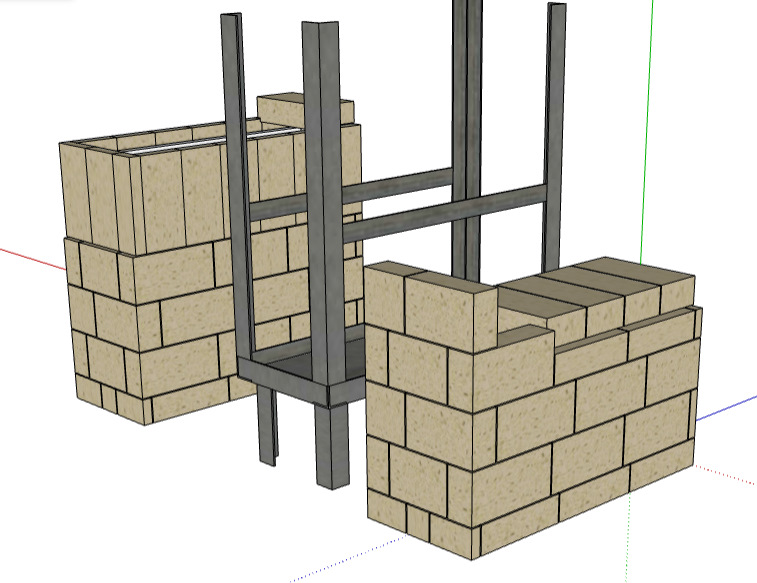

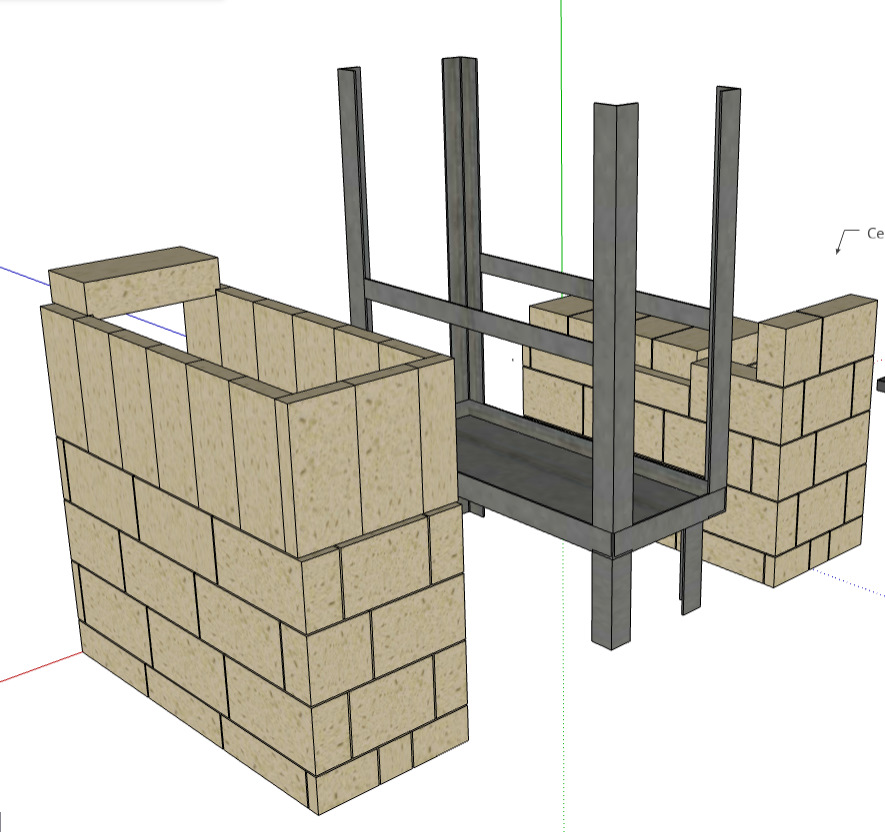

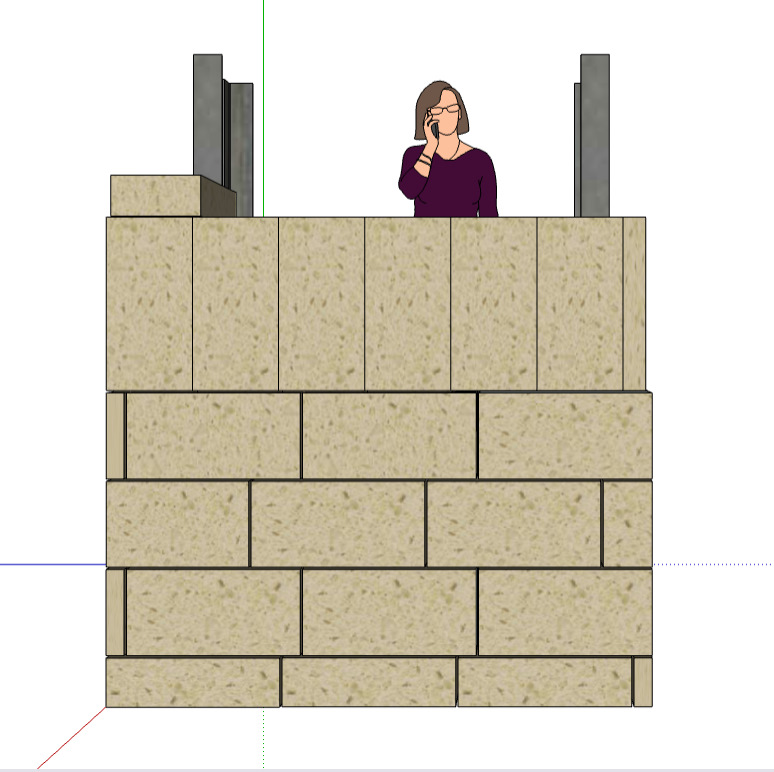

Process is moving. Size: 115mm. Box: W=167mm, H=250mm. Port: W=42mm, H=183mm, D=30mm brick + 25mm cerablanket. Fireclay chamotte brick with size: 230x114x65mm. IRL:    Size:  Model in SketchUp (in process):         I plan to weld metal skelet completely with metal sheets. Walls of upper box are made without glue, Bricks will be sandwiched. Inside Riser and inside top box I will be place 25mm cerablanket. Give me feedback, plz. |

|