|

|

Post by miquel on Dec 8, 2019 2:45:23 GMT -8

Hello, I want to transform my RMH bench to a DSR2 with bell and bench (http://donkey32.proboards.com/thread/2169/rmh-burn-properly-visible-smoke). I escalate the Peter's sketchup to a 200mm system. The issue for me is the depth of the DSR2. I was thinking to leave part of DSR2 outside the bell, but the exhaust stays out. Is possible to make a chimney in order to put the gases inside the bell? If so, wich are the dimensions of these chimney. Could be made of steel? Or to move the exit exhaust more to the bottom of the DSR2? Attach the sketchup.

drive.google.com/drive/folders/11oeX9ibarpuVh8Bs6xMyZTkAgfvJvzmT

Thank you in advance, Miquel |

|

|

|

Post by peterberg on Dec 8, 2019 5:49:49 GMT -8

Can't read the .skp file, it's in a newer version of SketchUp than what I am using.

To answer your question directly: no, you can't place a chimney elbow on the exhaust of the DSR2, simply because it's too hot in that spot. The exhaust need to be on top, not to the side. Changing the overall design will result in a system that doesn't work, almost quaranteed. Stick to the specifications that is known to work, it will save you from doing a lot of work with results that are highly questionable.

All that said, what is known as allowing some slack is the total depth of the firebox. Make that 20% shorter as a maximum and keep it to the same proportions. That might or might not be enough, but I expect it would do just as well. By the way, a 200 mm system is a really big cannon, you need a large space to utilise that. You could also opt for a 180 mm system I'd say. My development model is just 125 mm and already surprisingly powerful. Even more so than a straight batchrocket.

|

|

|

|

Post by miquel on Dec 8, 2019 10:48:03 GMT -8

Hello Peter, I save the sketch in version 2017 and made some changes as you pointed, I put three DSR2 system (200, 200 less 20% shorter firebox and 180 less 20% shorter firebox) in the sketch in order to see how they don't fit in to the bell. I want to do a 200 mm system because my previous RMH bench is these size and really need to warm a big old house. I just start to cast some pices of the DSR2 and saw the DSR2 won't fit in the desired bell. Another think will be to put DSR2 in X axis direction and put door in the side of the firebox. Do you think it could work? Thank you! |

|

|

|

Post by peterberg on Dec 8, 2019 12:35:13 GMT -8

I want to do a 200 mm system because my previous RMH bench is these size and really need to warm a big old house. May I remind you of the fact that a given batch box rocket is about twice as powerful as a J-tube of the same size? I just start to cast some pices of the DSR2 and saw the DSR2 won't fit in the desired bell. Another think will be to put DSR2 in X axis direction and put door in the side of the firebox. Do you think it could work? Please, don't do that. stick to the tried and tested design or don't build it at all. And if you want a batchrocket class of heater, why not consider a sidewinder which would fit in that projected bell? |

|

|

|

Post by miquel on Dec 8, 2019 22:16:23 GMT -8

My bench is about 10 meters long. A lower system will be enough powerful to push the gases out?

There is any proven design with DSR2 sidewinder?

|

|

|

|

Post by peterberg on Dec 9, 2019 1:08:50 GMT -8

My bench is about 10 meters long. A lower system will be enough powerful to push the gases out? Can't tell you that, I need to know the measurements of the bell plus the traject of the bench including bends and cleanout ports in order to do a rough calculation. Don't ask me to guess whether it will work or not, because I won't. A question: Is that the same bench driven by the 200 mm J-tube? There is any proven design with DSR2 sidewinder? I meant a normal sidewinder equipped with a riser. See for a tested sidewinder: batchrocket.eu/en/designs#core6There is no sidewinder DSR2 so it would be an untested core again, nothing to rely on. |

|

|

|

Post by miquel on Dec 9, 2019 5:31:30 GMT -8

The bench is the same driven by the J-Tube. When I will arrive at home I will take some measurements ant try to do a better sketch. If you take a look at the url donkey32.proboards.com/thread/2169/rmh-burn-properly-visible-smoke you'll see some pothos of the costruction made 3 years ago. Another option will be to put in the lateral firebox a fix glass, if the DSR2 is put in the X-axis direcction, in order to watch the fire. Do you think that will be possible? Or to risky to brake with the wood or temperature? |

|

|

|

Post by peterberg on Dec 9, 2019 5:40:55 GMT -8

Another option will be to put in the lateral firebox a fix glass, if the DSR2 is put in the X-axis direcction, in order to watch the fire. Do you think that will be possible? Or to risky to brake with the wood or temperature? In short: please stop trying to adapt the design to your situation, change your situation instead or have a serious look at the sidewinder option which sports less depth. Don't place glass in the side of the firebox, this wont be possible and will yield problems aerodynamically-wise. |

|

|

|

Post by miquel on Dec 9, 2019 12:49:47 GMT -8

|

|

|

|

Post by miquel on Dec 12, 2019 22:45:03 GMT -8

I think I gonna try the DSR2 for a 200 system with a 20% shorter firebox. I scalate your DSR2 design to a 200 system, then I made the firebox 20% less deep and I reduce 20% the deep of the box maintaining the distances of the exhaust with the door. I don't know if I explain right. Could you take a look if the design it's right? drive.google.com/open?id=1tpyVv291DtkKaWCcc_9Xf4SaPCOBH_PaThank you! |

|

|

|

Post by peterberg on Dec 13, 2019 2:39:29 GMT -8

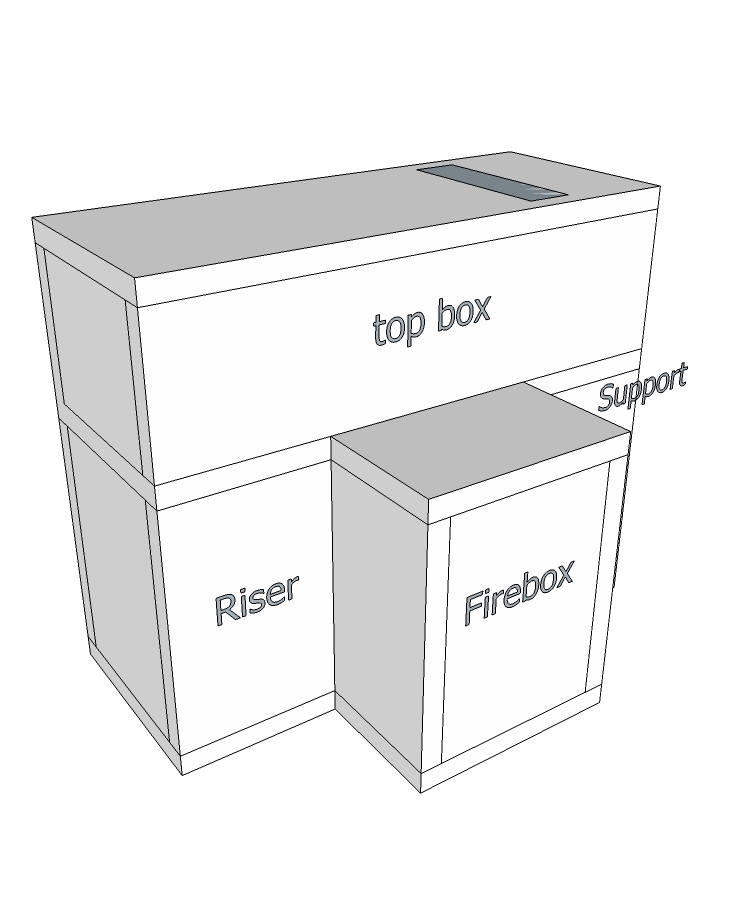

It seems the placement of the stumbling block and the exhaust port isn't right. Place the stumbling block halfway the internal depth of the top box, the exhaust one quarter from the front. In the mean time I sketched another possibility: the DSR2 sidewinder! Depth of the firebox is the same, riser stub is at the side, left or right. On top of that the top box, turned around 90 degrees in the horizontal plane. Based on what is known about how sidewinders work, all the parameters are right so this should work right out of the box, so to speak. It's untested, that's true, although all the right boxes are ticked. The fire doesn't know what direction it is going, the 90 degrees up and 90 degrees to horizontal are the same as in the tested model. Probably best to attach a sketch to illustrate what I mean, here it is. It's seen with the riser at the left, a support wall at the right, exhaust to the right. The back wall is flat, depth reduction about 30%. It's up to you whether or not it would fit in your situation.  |

|

|

|

Post by miquel on Dec 14, 2019 2:44:44 GMT -8

|

|

|

|

Post by miquel on Dec 14, 2019 3:11:22 GMT -8

In the following sketch you could see the bell with the sidewinder, It seems bell the will be waste.. the bell's walls lower than the DSR2 don't count to calculate the ISA, isn't it? drive.google.com/open?id=1E65M02Hj5UJNaH1KWzz1y3AsxKhukF0KWith time and if the system allows it I will put a upper bell in the second floor. |

|

|

|

Post by peterberg on Dec 14, 2019 7:04:09 GMT -8

I've had a look at the sketches, at first glance you've got the core right.

The core inside the bell doesn't look that good, though. There need to be more space to allow the gases to stream from above the core to below it, at least 5 times the cross section area of the riser stub.

I'd suggest you enlarge the bell at the right hand side so there's a larger hole beside the core. Additionally, recommended space above the core is the same as the system size, in your case 200 mm so your bell could be lower.

All the inside wall area do count for ISA, down to where the gases enter the pipe to the bench. Everywhere the gas is streaming along is ISA, so nearly all the space below the core is included in the heat extraction area.

|

|

|

|

Post by miquel on Dec 15, 2019 2:28:38 GMT -8

The riser stub is the riser? If so, I can't make the bell this dimensions,  Is there another way to proceed? Thank you!

|

|