|

|

Post by etownandrew on Mar 18, 2018 10:26:57 GMT -8

: Are you using a specialty adhesive for your foam sheets? Would cheap & widely available ABS plumbers cement work? I have used a hot glue gun to stick together foam pieces for other types of projects. It works well and is quick. I imagine that I would use the same method if using a clay-based casting material that did not shrink. |

|

|

|

Post by pigbuttons on Mar 18, 2018 11:23:29 GMT -8

I don't know about plumbers cement as it is actually a plastic welding type chemical. I used standard Elmer's white glue and it held together well enough to place the cement around the form. This time though I intend to use Barge cement which is more of a contact cement and it should be more durable of a bond.

|

|

|

|

Post by smartliketruck on Mar 18, 2018 11:33:09 GMT -8

I just tried the ABS cement and it is far too aggressive to use on foam.

Hot glue will be fine for final assembly but I'm thinking of how to form cohesive blocks that can then be sawn or hotwire cut.I'll give school and carpenters glues a try next.

|

|

|

|

Post by smartliketruck on Mar 22, 2018 18:06:43 GMT -8

I gave carpenters and school glue on some EPS chunks, It appears I laid it on too thick and should have let it tack up much more before sticking together, where it did cure/dry on the outside edges the bond was more that sufficient as it was stronger than the foam. As one of my favorite youtubers likes to say

"A little dab will do ya, a big gob will screw ya!"

Playing with the foam reminded me how much I hate this stuff, If I play with it again I'll be making a hotwire cutter first and probably some use spray adhesive also.

I built another form this time of cardboard & tape, my mixture is self supporting at room temperature in less than 2 hours, so it should work.

|

|

|

|

Post by keithturtle on Mar 22, 2018 21:00:33 GMT -8

|

|

|

|

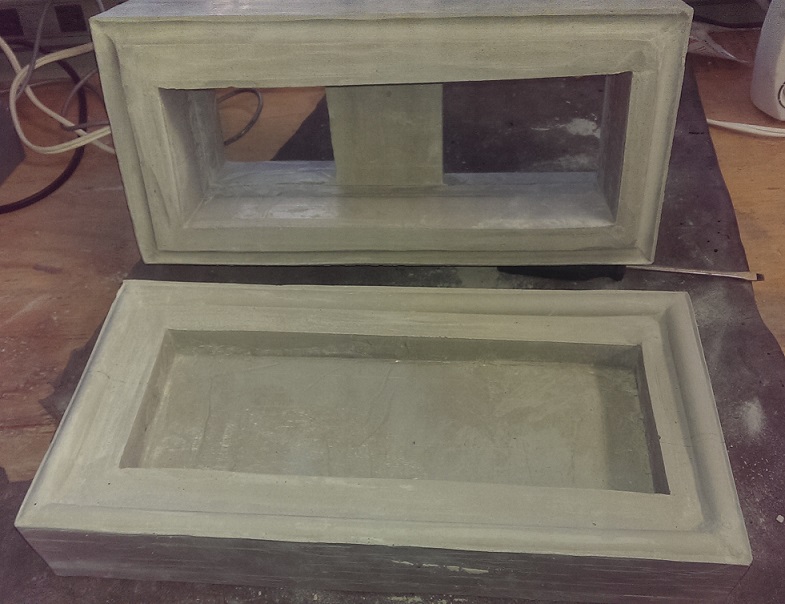

Post by smartliketruck on Apr 8, 2018 16:04:34 GMT -8

Cardboard and tape worked well for casting this, I just need to add a little additional support on some of the longer spans. Casting in layers like I did will hopefully allow me to easily recast any piece with an altered mixture. This time around I painted between layers with liquid castille soap instead of vegetable oil and I'm happier with the results.  Some cracking shows my mixture needs some adjustment, this cracking was not present with earlier casting of simple ~1" thick tiles. The cracking is not so bad that I can't test fire it. I'll give it a try tonight. |

|