|

|

Post by nedreck on Dec 18, 2010 9:04:41 GMT -8

Hello to one and all. Gonna be doing some stress testing on these toys boys and I am gonna play mad scientist while doing so as well. whole thing is in the embryo stage at this point and need to gather a lot od data proper to construction of a test unit but the good part is I won't have to bother with gathering a lot of testing gear, I already have it  I will be back with more, Donkey knows how I got here, I suspect others do to, just remember old Ned is a good guy, just not particularly polite, aint real friendly, and really only interested in the science part. Look forward to a free exchange of data and hope you find my input useful to your efforts. Ned |

|

|

|

Post by alergyfree on Dec 18, 2010 9:20:10 GMT -8

Hello to one and all. Gonna be doing some stress testing on these toys boys and I am gonna play mad scientist while doing so as well. whole thing is in the embryo stage at this point and need to gather a lot od data proper to construction of a test unit but the good part is I won't have to bother with gathering a lot of testing gear, I already have it  I will be back with more, Donkey knows how I got here, I suspect others do to, just remember old Ned is a good guy, just not particularly polite, aint real friendly, and really only interested in the science part. Look forward to a free exchange of data and hope you find my input useful to your efforts. Ned Looking forward to your posts |

|

|

|

Post by Donkey on Dec 18, 2010 10:00:09 GMT -8

Thank you for coming Ned..

Welcome.

I (for one) am looking forward to your input!

|

|

|

|

Post by nedreck on Dec 18, 2010 15:32:08 GMT -8

Well lets get some fundamental stuff out of the way.

Anyone done drawings of some of the designs that have been done?

Has anyone studied the fluid dynamics of the fuel path from beginning to end?

What does the flame pattern look like in the riser?

Anyone measure the actual velocities?

I have read some folks saying that they are getting a positive pressure on the exhaust side of theri stove any one here make such claims?

Why the square heat tunnel?

Those are just a few of the slap me in the face oddities that seem un answered most of the time.

|

|

|

|

Post by Donkey on Dec 18, 2010 16:52:17 GMT -8

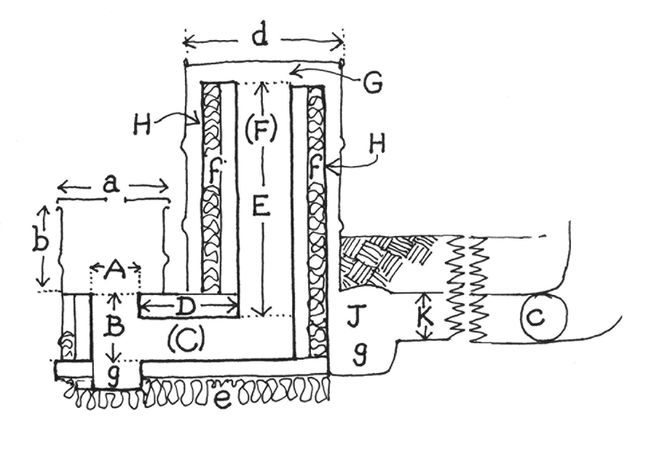

Well lets get some fundamental stuff out of the way. Anyone done drawings of some of the designs that have been done? Yes. I'll try and look some up and post 'em a little later on. In the mean time, this one's out of the book (and I have permission to use this). I can give the dimensions a little later as well.  Not to my knowledge. I've been trying to watch it carefully and have noticed a few things and built a "mental model" that seems correct so far. A true scientific study (or even an unscientific one) has NOT been done. Good call though. Depends. You can add turbulence generators that alter the shapes. Typically though, it's a fairly cohesive flame-tongue (with chaotic edges) that tends to spiral off the bottom of the heat riser twisting as it rises. Not to my knowledge. I haven't noticed, nor have I read such here (yet). This one should be easy to check. What degree of positive pressure? Should it shove a piece of paper (placed in the way) out of the way?? What exactly are the claims? 2 fold.. Easy to build out of cheap material and MOST IMPORTANTLY, creates turbulence. |

|

|

|

Post by Donkey on Dec 18, 2010 17:31:21 GMT -8

Umm..

On second thought.. If my hypothesis of how rocket stoves work is correct, perhaps we should see some measure of positive pressure on the exhaust side..

Like I said, should be easy to check.. I'll get back to 'ya on that one.

|

|

|

|

Post by Donkey on Dec 18, 2010 23:27:24 GMT -8

Here are two images looking down heat risers. Neither are insulated, the square one is an experiment made out of adobe brick.   |

|

|

|

Post by nedreck on Dec 19, 2010 7:57:03 GMT -8

Umm.. On second thought.. If my hypothesis of how rocket stoves work is correct, perhaps we should see some measure of positive pressure on the exhaust side.. Like I said, should be easy to check.. I'll get back to 'ya on that one. Well it will not really be "easy" to check because it is going to be fairly minute in nature. What MIGHT exist is a slight increase in pressure that is less than the vertical lift of the buoyancy, it can not be more than that since vapor pressure pushes equally in all directions. What might exist is slight velocity increases upward due to the thermal expansion of the vapor that are not strong enough to overcome the kinetic energy already moving it upward from the thermal draft. In other words what comes in must go out, however that does not dictate the velocities it will travel through out the system and that means the "mass" not cubic feet. as the density thins due to the increased temp, the velocities increase to carry the same mass. I should have seen this from the begining and now it makes sense on how they became named "rocket" stoves. |

|

|

|

Post by Donkey on Dec 19, 2010 12:27:31 GMT -8

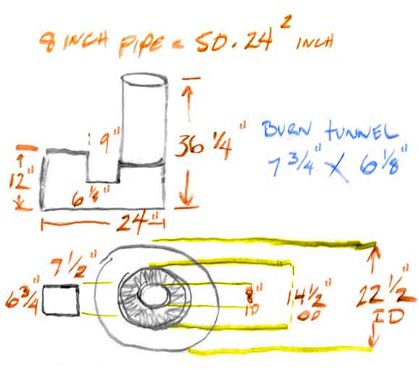

I built a sauna with a rocket stove for heat. It works QUITE well, the top of the barrel at times glows red and if it weren't for the lava rocks placed on top, would probably have melted through by now. The internal dimensions are thus:  The stove core, put together looks like this:  It sets down into the floor like this:  And the whole thing from the outside looks like this:  |

|

|

|

Post by canyon on Dec 19, 2010 13:53:41 GMT -8

Well lets get some fundamental stuff out of the way. Why the square heat tunnel? There is no requirement for this stuff, just different set ups and different results. The book has a standard working model which Donkey posted a drawing of above and that has a square heat tunnel for various reasons I am sure of which ease of construction with easy to gather materials plays a large part. I am building a arched burn tunnel and look forward to getting the results of my particular set up and sharing them (tentative construction schedule of late February 2011). Round is effective as well. I like to incorporate the curved form for the inherent reflective (even focusing particularly in the case of parabolics) bonus and I appreciate the extra room for horizontal loading.  |

|

|

|

Post by nedreck on Dec 19, 2010 14:51:44 GMT -8

What the heck is this thing anyway?

Well, it is basically a crude direct fired oxidizer, an afterburner if you will since that is all a direct fired oxidizer actually is, looks like we have the source of the rocket name.

Burning wood or biomass gives rise to inorganic particulate matter or fly ash, just because it is not visible to the naked eye does not mean it is not there. The EPA regulates fly ash because it is made up of a lot of nasties. Short of filtering the exhaust in some manner, fly ash is going to exist in the system, there is no way around it. Fly ash from wood combustion is high in alkaline earth metals like sodium, potassium, magnesium and calcium and perhaps others.

These products of combustion can be aggressive on other materials and are known to be very aggressive on ceramics like those found in an RTO (Regenerative Thermal Oxidizer) which in a real twisted up way is sort of what a RMH (rocket mass heater) but a closer match would be a direct fired oxidizer with an attached heat exchanger.

Without dimensional knowledge it is hard to say exactly what processes are taking place, however, it is fairly safe to hypothesize that an adiabatic compression of the fluid (fuel air mixture) is occurring, The mixture is probably quite similar to air and the Reynolds number if developed would likely indicate it is prone to turbulent flow. This is a good and bad thing depending upon desire, it is good in that it increases friction losses, reduces velocity, and creates negative pressures within the mix. It is goon in that it provides a good fuel air mix, prevents heavier elements of the composition from dropping out, and spreads heat more evenly across heat exchangers.

The reason I asked what the flame looked like was to try and determine what processes might be at work and I think you for the feed back. You stated it was like a tongue with uneven edges then swirls out which was exactly what I was looking for and it makes a lot of sense as to why slight design changes impact operation significantly. In the tunnel you have what would very likely be laminar flow down the center of the shaft due to lower resistance and turbulent on all four sides with even odder flow patterns in the corners. This is going to create pressure zones within, low in the middle and high on the sides.

By turning the corner you create very different pressure zones within the fluid that already contains slightly different pressure zones, this is what creates the vortex flow. For those not familiar with what I am talking about, you can some what directly compare this to a tornado. A temperature and flow difference begin to chase each other so to speak which creates an even lower pressure in the center, when it crashes into and opposing pressure instead of dissipating it increases in intensity and builds energy drawing from both pressures, the high side driving the spin and the low side providing the heat in the form of latent heat from the moisture on the low side. This effect would be enhanced because of the distance difference in the top of the tunnel vs the bottom of the tunnel.

While this is kind of a crude hypothesis of the fluid dynamics, the described failures of different designs would support it. If the intake port too large a significantly different flow pattern would exist, if the riser was too small the pressures could increase to cause reverse flow (smoke back, puffing operation, failure to light off the oxidizer etc) if the riser were too large, the pressure differential created in the burn tunnel could be reduced enough to prevent the vortex from forming and building energy intensity aka temperature to properly drive the exhaust. The “barrel” chamber would not be as critical, however it could certainly impact the whole system if it was too small. This may have more to do with intake, tunnel, and riser sizing more so than anything else due to the common 55g barrel or similar sized substitute. Significant changes to those dimensional relationships may well be quite possible as long as one follows suit with the space allowed after the riser for controlled expansion.

While the cylindrical design of the riser lends itself to the vortex flow, the efforts to “improve” it through the conical design will likely not “improve” but will raise the heat intensity aka temp and will raise the hottest point in the riser closer to the top of the riser. This would be an adiabatic increase in intensity so it would not result in more energy extracted but more of a location shift and release of equal energy at a higher intensity but smaller mass netting the same quantity of energy release.

References I will be using to confirm some of these design characteristics are:

Thermodynamics and heat power, Seventh ed, by Granet and Bluestein

Thermodynamics and heat power, Fifth ed, by Rolle

Thermal Environmental Engineering, Third ed, by Kuehn, Ramsey, and Threlkeld

As I reference these in discussions I will paraphrase and only use very minor portions and formulas that are widely known engineering practices as I have no permissions beyond educational purposes. In other words, I will provide them as the path to proof of concept where one can use the method if that makes sense.

From a very real perspective, this information will be provided in an amateur language to assist amateur hobbyist proceed with a hobby having far more information that will improve safe practices but will not guarantee absolute safety and a great deal of caution should be used when applying it. While wood burning itself has relatively mild risk, superheating the gasified vapors considerably above the flash point and to the auto-ignition temperatures even under the mildest of pressures when in the presence of oxygen can have very hazardous results. The entire vessel may indeed over pressure if circumstances are right resulting in significant blow out of the vent and firebox and if it is large enough and rapid enough it may dislodge portions of the vessel or rupture it.

This concern is very real considering the standard 55 gallon drum design employed in so many of these units. There is approximately 452 square inches of flat surface on the drum top and assuming it is an ANSI standard it is fairly light weight and is not certified as any type of pressure vessel. A small pressurization of only 10 PSI would be 4,520 pounds of upward thrust which is significantly more than the material or the resistance welded seams are designed to withstand. While it has yet to be explored as to whether or not dangerous over pressures can occur, as there seems to be a reoccurring discussion about making these units larger or greater capacity and designers should pay significant attention to redesigning the head to withstand and redirect overpressure conditions to limit damage possibilities.

In other words, a big flat top might seem great for cooking etc, but it is a bad idea when working with even minor pressures are possible, there is a reason pressure vessels are domed instead of flat and while perhaps not as usable or as industrial looking (it’s a man thing), they increase the capacity of the same thickness metal significantly.

These are my thoughts and my hypothesis surrounding various manners in which this device operates, no pencil to paper on it yet to confirm, if anyone knows a portion to be totally incorrect, please by all means bring it forward. I am just beginning to think about them seriously and would rather work to provide you with information you are missing vs correcting my own misunderstandings in the beginning stages.

|

|

|

|

Post by northriver on Dec 19, 2010 20:16:50 GMT -8

Anyone done drawings of some of the designs that have been done? Why the square heat tunnel?  I've inserted a scaled drawing of the unit I am in the process of building (7"x7" throat). A scaled PDF of this drawing is available here (http://www.darfieldearthship.com/wp-content/uploads/2010/12/massheater-xsec.pdf) as long as you have access to a plotter. I have annotated the two dimensions that varied slightly between the design on paper and the as-built unit. If you cannot plot the scaled drawing let me know what I can do to make it available. This unit is based on the design from the Rocket Mass Heater book by Ianto Evans. As has been stated before the square tunnel simplifies construction. The only part of this unit that is not faithful to the drawing is the manifold. However, I did ensure that the area of the entrance to the manifold (from the heat riser) was slightly more than 49 square inches. |

|

|

|

Post by canyon on Dec 19, 2010 20:18:32 GMT -8

Man, thanks for getting on this board! Would you mind sharing a bit about your background to keep people like me from wondering and allow for more sharply tuned dialog?  |

|

|

|

Post by northriver on Dec 19, 2010 20:35:44 GMT -8

A question about your statement on fly ash ...

As you mentioned, fly ash is a byproduct of wood combustion. Are you simply making an observation about this, or are you wondering/suggesting that it is a more significant issue with rocket mass heaters?

Possibly answering my own question (after thinking while typing)... if the exhaust gas cools to its dew point then the fly ash would percipitate out in the flue.

|

|

|

|

Post by nedreck on Dec 19, 2010 21:37:39 GMT -8

Man, thanks for getting on this board! Would you mind sharing a bit about your background to keep people like me from wondering and allow for more sharply tuned dialog?  Sure, however it is actually more likely that it will make you wonder a lot more lol. I have close to 30 years working within the thermal energy fields. I have a bit more experience than that but working with mt father crawling in and out of boilers does not really count! I will refrain from identifying myself and will request Donkey keep my identity private as I intend on posting from the college as well as home and I seek my privacy, if I did not I would write a book  My background includes some fairly exotic stuff like VOC recovery, distillation processes, thin film evaporation, Oxidation of VOC compounds, carbon bed absorption, coal, oil, gas and fuel oil fired boiler systems, absorbers, vapor compression refrigeration and air conditioning, electrical engineering, welding processes and some more stuff  About 30 years ago I worked for a mason rebuilding 3 chimneys but only as a mud dog so other than learning it was too much work I can't claim to do more than pity the backs of the masons! In 2001 I began teaching at the college level up to a BS in thermal engineering which I was the department chair within a year. I am now the department director for 4 of the sciences and have approximately 1,500 students in my charge with about 50 instructors and 4 department heads. Nothing really exciting there, just an absolute LOVE for thermal engineering and the heat transfer process. I have not invented anything though I have improved a few things over the years and been on the design team for projects ranging from 5k through perhaps 25 million dollars, I do not really know what the "biggest" was, to me it was just work lol. I am an INTJ personality type and if you google it you will likely have a better understanding than anything I would explain. As a teacher I abandon the traditional theory of teaching and resolved that I did in fact not teach anyone any thing, I simplified things to help others figure things out. I found that teaching really does not happen with adults, they have to figure it out and buy into it themselves and all you can really do is lead the down that path. I hold many licenses including a PE license that allows me to operate coal or gas fired power plants, well any type of power plant with unlimited prime mover. What can I say, I love it, I am totally passionate about thermal systems whether it is a 30k hp boiler system or a frosted counter at a Vodka bar! I have very little experience with wood systems, but truthfully whats the difference? Fuel is fuel and the key is actually the thermal energy involved and the flow, the fuel is really unimportant other than changing the numbers that get calculated. There are lots of others more suited to the job, I am just interested in it to a degree and it will sharpen some skills getting rusty not to mention I will learn a lot of new things as well as learn some things lost due to a lack of use. Beyond that you will have to ask directly. Oh, I got on this path because of a fuss over the false claims some folks make about these toys and I am kind of open for arguments some times and while I was trying to avoid one, it got my passions going and now I have to sort of prove my own points to myself again. Ned |

|