|

|

Post by Orange on Nov 13, 2017 6:22:11 GMT -8

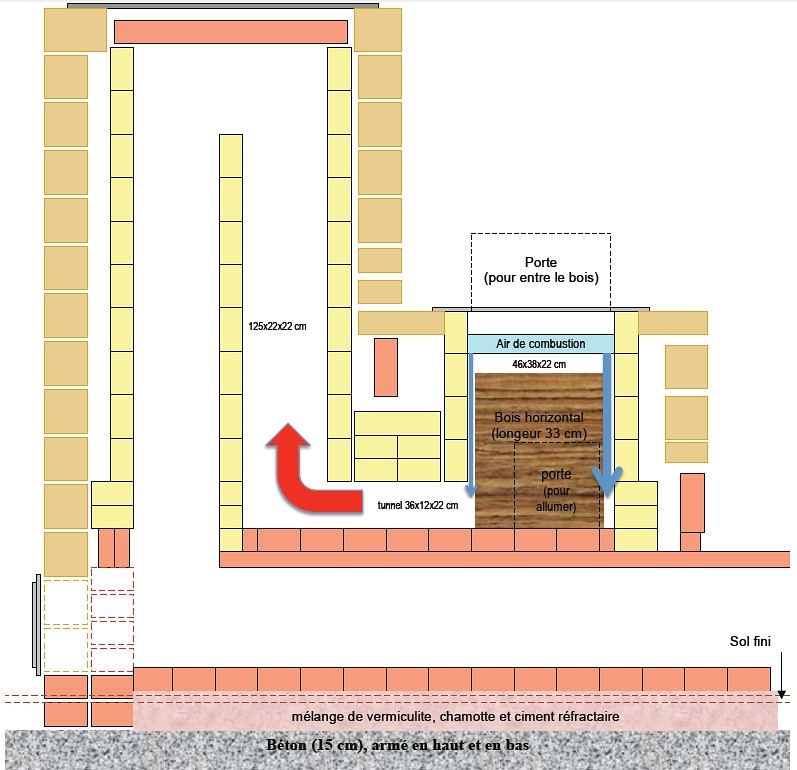

Size: 17cm, 6.7inches Usage: heater, cooker, bench, bed Firebox, riser: ceramic fiber board 2cm (less than inch) Binder: clay&sand Primary bell: red brick, firebrick, 4mm metal plate Bench/bed: red brick, 2mm metal plate, magnetite and cob Chimney: metal (2.5m) + chamotte (4m) Bell to wall insulation: rockwool 10cm Bell to floor insulation: EPS-100 3cm+wood 2cm (not enough space for more insulation) SKP file: linkSpace is tight so some compromises had to be make:             |

|

|

|

Post by Orange on Nov 13, 2017 6:34:50 GMT -8

Comments and critiques welcome!

Concerns:

-will it work?

-support for bell/bed metal plate creating too much resistance?

-is it possibe to sleep on high termal radiation?

-asymmetrical position of riser?

-small riser?

-is port depth of 6cm maybe better for this project?

|

|

|

|

Post by peterberg on Nov 16, 2017 11:37:12 GMT -8

I'm inclined to think your heater will show unpredictable behaviour, given the short riser and the tight top gap.

|

|

|

|

Post by pinhead on Nov 16, 2017 11:37:45 GMT -8

Peter is the expert about the batch core so I'll let him comment on that.

With regards to the bell bypass, however, I'm afraid your system as-is won't work.

The second bypass picture is better than the first, but still has a deficiency.

If the bypass isn't above (higher elevation than) the entrance to the bell, it won't function as a bypass in a bell system. Especially in a bell system as voluminous as your drawing - which I love, btw.

I also must mention that the bypass must have a direct path to the chimney in order to be effective. In other words, if the entry of the chimney is still lower than the bypass, the entire system will still act as one large bell.

The best location for your bypass would be at the back of the primary bell directly into the chimney.

Add a Tee to the chimney and insert it about half-way down the primary bell. With a well-sealed flue damper between the Tee and the primary bell, you'll have perfect chimney temperature control with a twist of the wrist.

EDIT: To envision the flow of hot air in the bell, imagine you're filling the system with water - though the system fills from the top down, instead of from the bottom up.

Alternately, you could envision taking the entire system and fliping it upside-down. In that configuration, filling the bell with water (flowing in from the heat riser) you'll see how the bell works.

|

|

|

|

Post by Orange on Nov 17, 2017 3:42:26 GMT -8

I'm inclined to think your heater will show unpredictable behaviour, given the short riser and the tight top gap. i'm afraid of that, yes. If you put batchbox low to the ground it becomes unpractical to use. If you build the bell high it becomes umpractical too cook. I'll make the top gap 18cm and port depth 6cm, similar to your riserless model. |

|

|

|

Post by Orange on Nov 17, 2017 3:50:29 GMT -8

The best location for your bypass would be at the back of the primary bell directly into the chimney. Add a Tee to the chimney and insert it about half-way down the primary bell. With a well-sealed flue damper between the Tee and the primary bell, you'll have perfect chimney temperature control with a twist of the wrist. EDIT: To envision the flow of hot air in the bell, imagine you're filling the system with water - though the system fills from the top down, instead of from the bottom up. thanks, I get the picture! |

|

|

|

Post by woodrascal on Nov 17, 2017 7:48:05 GMT -8

Hi Orange - if you're worried about the cooking height have you seen Matt Walker's riserless cookstove? Maybe you could adapt your design? Cookstove |

|

|

|

Post by Orange on Nov 17, 2017 8:14:24 GMT -8

Hi Orange - if you're worried about the cooking height have you seen Matt Walker's riserless cookstove? Maybe you could adapt your design? CookstoveIt's one of my favourites. But, he's and expert and i'm a rookie. And my sketchup includes a non-traditional bench-bed which could cause problems:  |

|

|

|

Post by satamax on Nov 17, 2017 22:20:25 GMT -8

For cooking, there is another solution. Cast iron top on the firebox.  |

|

|

|

Post by Orange on Nov 18, 2017 2:29:10 GMT -8

hmm, how much does it take away from the clear burn? Nice idea but then it doesn't make sense to use ceramic materials when there's iron on top  Here's a sketchup, with the full riser it just looks too massive: |

|

|

|

Post by satamax on Nov 18, 2017 5:14:20 GMT -8

Well, orange. I followed Peter. He had, at the time; fited a glass plate above the firebox. I asked if it was not detrimental to the burn. And he replied no. So i emited the idea, publicly on the forum. donkey32.proboards.com/thread/1568/batch-cooker?page=2And finally johndepew beat me to it. |

|

|

|

Post by Orange on Nov 18, 2017 13:20:08 GMT -8

thanks Sata for the input. i like your riser window, maybe I'll steal the idea  Let's say insulated firebox temp is 300C. If you put the metal plate you can cook well but the temp inside drops to 150C. So air entering the heat riser is 150C cooler which is not a big deal but you probably wont get glowing red iron on top of riser. |

|

|

|

Post by satamax on Nov 18, 2017 13:29:09 GMT -8

Really, there is far more than 300c in the firebox. I cooked two steaks on the stove tonight. Two minutes per side, in a cast iron tray, is too much. It was ready to Cook in under two minutes. I went on the roof today. Chimney, on it's third winter, is barely black. So it must be running OK. Why dont you build a test stove in your garden, son you can assess the usefullness of the cast iron cooktop.

Myself, i like it.

|

|

|

|

Post by Orange on Nov 21, 2017 13:28:31 GMT -8

|

|

docbb

Junior Member

Back from ZA

Back from ZA

Posts: 92

|

Post by docbb on Nov 22, 2017 4:31:40 GMT -8

okay, to keep things simple, I'll first power the system with 16cm J-tube with 100cm riser (from the bottom). Skp file is here: rocketalso, by having the cooktop low, it heats up the living space faster.  A batch J see also donkey32.proboards.com/post/26006  |

|