|

|

Post by kbhale on May 24, 2010 23:08:58 GMT -8

I want to make hot water to heat my home. The hot water will be made in the out building and pumped to the house. I have a 500 gallon hot water tank in the out building. There is also a tank in the basement of the house also.  This is an old, 30 gallon hot water heater tank. It will be in the place of the blue. I have 50 gallon barrels to go over the riser and the water tank. Plan to put 1/2" copper around the riser.  This is my learning model. Ive learned a lot. Any input welcome. |

|

|

|

Post by canyon on May 25, 2010 6:51:28 GMT -8

Looks like an interesting project! Don't leave out a pressure relief valve whatever you do! My experience with 1/2" tubing is it tends to flash to steam alot easier in thermosiphon situations and I try and stick with at least 3/4". I imagine you are pumping so as long as you can keep up the flow rate it works. I like to also have an air purge valve (coin vent usually) located at the high spots. Anyway, I hope you keep us updated as experience in this kind of project is valuable to alot of people. Thanks!  |

|

|

|

Post by kbhale on Jul 4, 2010 21:02:16 GMT -8

This is the rocket, I built to use as a backup hot water heater. I been using it to make hot water for my BBQ kitchen. It works but it needs to be better. A bi-metal switch kicks on a 12v DC pump at 150F. It has a 20 degree differential. Circulates water from the 500 gallon storage tank.  What I'm planning to do is, instead of the rocket venting up the chimney. I'm going to vent it into another barrel containing the hot water tank in the picture. Then up the chimney. Have it on a separate bi-metal switch and pump. Try to capture as much heat as possible.  Here is the part where plan to make the rocket better. Instead of the furnace pipe I'm going with masonry and stainless steal. I built this as a cooker for now to work the bugs out. When I go to rebuild the rocket water heater. Copper tubing well be wrapped around the top of the half barrel and a barrel well be placed over the riser and half barrel. I'll need to extend the riser to get the proper clearance to the bottom of top of the barrel, when I do the final build.   You can almost see the flame burning sideways in this picture. |

|

|

|

Post by canyon on Jul 11, 2010 16:37:21 GMT -8

I had a beer the other day that said "great minds drink alike"on the bottle cap. Your post made me think something like "drinking minds sink alike" but whatever, I am excited to see more keg art! Keep it up!  |

|

|

|

Post by Donkey on Jul 13, 2010 7:35:59 GMT -8

Cool project!

I'm really liking the creativity in re-use of materials.

Keep posting!

|

|

|

|

Post by kbhale on Jul 18, 2010 21:08:45 GMT -8

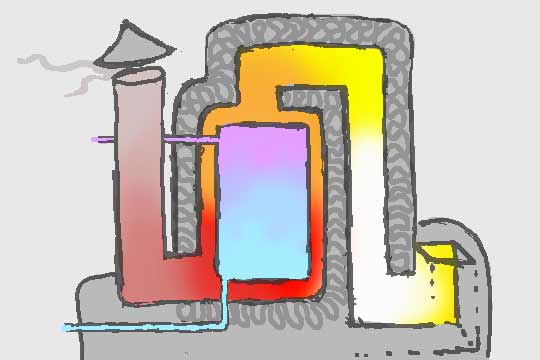

Spent most day deconstructing my two rocket stoves to rebuild the new one.  Laying it out. No mud yet.  The heat will fall over the riser and enter the barrel holding the water tank. I hope.  All recycled material  The barrel with the water tank I plan wrap with fiber glass, chicken wire and coat with cob. Maybe the same with the rocket stove sides.  I'd like to Avoid heating the room, when heating the cooking pot and the water. I'll put an exhaust toward the top of the water tank barrel and chimney out the roof. |

|

|

|

Post by Donkey on Jul 19, 2010 7:15:42 GMT -8

Ah.. My advise: Put the chimney at the bottom of the water tank barrel, NOT the top. Heat in at the TOP, exhaust out at the BOTTOM. You'll get better heating that way, as only the coolest gasses will fall and escape, like a bell stove. Like this:  Except you're using different materials, but grok the concept here.. You could leave the heat intake at the bottom which is even more like a bell stove and is what you've already started, but DEFINITELY, bring the exhaust out the bottom as well! |

|

|

|

Post by kbhale on Jul 24, 2010 21:46:26 GMT -8

Thanks about venting the chimney from the bottom. It made things a lot simpler. It should help heat capture, a lot.  Spent most of the morning stacking block and brick in different designs.  Hope to finish it enough tomorrow, that I can fire it. I want to check the draw before plumbing it tight.  Nuisance. Just mad, I used his cat litter for crack filler. |

|

|

|

Post by kbhale on Jul 25, 2010 21:44:45 GMT -8

Just mud enough to seal it up.  It could be drawling a lot better. I did a thermal scan where the chimney starts 95.6F. About 10 degrees warmer than ambient temp. About half hour into the burn the tank barrel was 103F on top. The rocket barrel top about 260F. I do have two gallon of water heating up.  Water from the storage tank, pumps through the coil first than into the tank. From the tank it goes back to the storage tank. |

|

|

|

Post by kbhale on Jul 25, 2010 23:09:49 GMT -8

Just shut things off outside. Rocket stove burning what wood one could fit in half a five gallon bucket. Raised 500 hundred gallon of water 3 degrees. Plus brought a soup pot up to temp for over an hour. Right now, the heat sunk into mass is no thrill but this winter it will be welcomed.  Insert happy dance here. |

|

|

|

Post by Donkey on Jul 26, 2010 8:41:32 GMT -8

Cool that you got it working.

2 questions though...

Do you plan to take the paint off of the barrels?? If not, is the paint that's on there heat resistant?(if not, it's off gassing toxins)

Did you say you are pumping the water through the coil?? Like with an electric pump? I hope you have safety valves on that thing.. If the power fails, you got a bomb there.

|

|

|

|

Post by kbhale on Jul 26, 2010 23:39:45 GMT -8

The painted barrel is in a ventilated, non living area. It should burn off safely enough. Before things get closed up for cold weather. I was wondering if it would be possible to clean the paint off the top of the barrel cleanly enough to cook on? Treat it like cast iron, once down to bare metal. The tank does have a pressure relief but I'm already thinking about doing away with it. I decided I don't burn the rocket stove long enough to get usable heat gain from the tank. I think adding a roll of 3/4" inch copper around the riser will give better heat capture. The bomb www.youtube.com/watch?v=JmJoyuUJj2Q |

|

|

|

Post by kbhale on Aug 9, 2010 22:36:36 GMT -8

Ok the hot water tank is gone. to dangerous. Added some more junk copper tubing. I cut a barrel and put it over the coil I added. I already plan to do away with the short barrel and just set a full barrel over the coil this winter. Fill it with wood to dry or water for a heat sink.  The masonry I stacked for the riser above the half barrel I did away with. Cut the cover barrel shorter to get the pot off and on easier. This is what I found interesting. The water in the pot would get very hot but never boil. The other day I covered the lidded pot with a large dome. It kept the heat radiating from the entire top of the rocket contained. Within a few minutes the pot was boiling. Now I'm thinking oven / smoker. |

|

hpmer

Full Member

Posts: 240

|

Post by hpmer on Aug 10, 2010 12:41:22 GMT -8

I wonder if you are stealing too much heat from the riser. The magic in the rocket stove lies with an insualted heat riser so all the heat stays in to cleanly burn the gases. A coil of pipe around the riser seems to me would defeat the most important part.

I wonder if you left the riser as an insulated piece but added a simple down pipe onto which you coiled the water pipe if you wouldn't get better (and cleaner) results. You could then connect this down pipe to your thermal mass to suck out whatever heat might be left over.

Cool project, though.

|

|

|

|

Post by wrekinwanderer on Sept 28, 2010 13:13:17 GMT -8

Just wondering if hpmer, or anyone else, could expand on where exactly to add a down pipe from which to harvest the heat for water heating?

Am thinking of using this water for water heating and possibly for radiant heating of a floor, or two. I wouldn't have to make such a deep hole in my floor then, as I would to accomodate an 8inch pipe....

|

|