|

|

Post by travis on Oct 27, 2017 19:56:53 GMT -8

Alright that sounds great. Thanks for the information. Im hoping to start planning for a build soon so the inspiration is awesome. It will be very good to see how it responds to larger wood.

|

|

|

|

Post by rakettimuurari on Oct 31, 2017 3:55:32 GMT -8

- BREAK IN FIRES FOLLOW UP - Its my third day with cord-wood. The load is something like 2,5 - 3kg large. I am adding 1kg per day to the load. Two fires per day, separated by 12hrs. This was first day the walls got warm outside! Upper half of the heater is uniformly warm from all three sides after some 4-5 hrs from the fire. Little less warm than hand; perhaps some 25 to 30 Celsius (I don't have proper measuring device yet). Firing behavior stays good or has slightly improved. Bypass still not needed. Regrettably I am doing the break ins and drying fires without proper floor channel as I will be getting it only in one week. For now I have only the horizontal part of the floor channel/ secondary air in place. Under air requires that bottom wood pieces cannot be too tightly laid but other than that it burns with nice roar. Secondary air is obtained through the door vents. Ash box with cast iron hearth in the bottom of the fire box has proven excellent and handy. Only leftover is finely pulverized ash in the box. THE OVEN So far the small loads have not been able to heat the oven too much and it is not retaining heat for too long. the peak has been in 150 Celsius. Also the fly ash makes the oven quite messy which is not really big problem. I just loved the original beige look of the firebricks  I believe this will improve with bigger wood load when the heater walls also start to be warm below the oven level. If redone, I would consider the possibility to exit the exhaust through the oven wall instead of the ceiling vault thus maybe creating the oven more bell like space ... I have extra refractory piece which is possible to install in oven ceiling in order to create a heat pocket in upper back part of the oven. We'll see. First full batch will be pyrolyzed during next weekend. |

|

|

|

Post by Orange on Oct 31, 2017 4:12:16 GMT -8

it's nice that bypass is not needed  Strange for the low temps in oven. |

|

|

|

Post by rakettimuurari on Nov 3, 2017 23:26:35 GMT -8

First full batch and floor channel in placeIs there Boeing 747 in my living room? No... it is my first full batch burning! Floor channel was built yesterday and it still made great deal of improvement. Most visible/ audible change is in heater acoustics; now there is a distinctive higher pitched rumble which seems to originate from the heat riser; even if i decrease the primary (under-air) intake - secondary air is all open. I would assume that is a good sign; after-burner now seems to have its own life. Heating capability As for heater my expectations are already met. Total mass of 2500 kg and solid oven structure + support columns inside seems to give good heat reservoir. Surface is hottest some 5 hrs after the climax of the burn and top of the heater is not too hot to touch (except areas around firebox and oven) - estimated 50'C. After 12 hrs it is still warmer than hand and all this with some 6-7 kg of 1,5 years dried spruce cord-wood. What makes me even more satisfied is that this all is achieved with no chimney damper in place. If I would leave the same sized contraflow masonry heater of my childhood home with chimney damper open overnight after fire, there would be no warm walls in the heater in the morning. I would assume this is again one advantage in system with bell operation as most heat remains at top of the bell even when the airflow is free through the system after the burn. Moreover, now when the drying and break in is completed I am going to install the regular cast iron sliding damper close to the rooms ceiling level into the chimney stack, like we do here. By that, many additional hours are likely to be gained in heat reserving capability. Disclaimer: I know that many users in other "heating cultures" are against the dampers but here it is just the regular way of doing it and many of us here still grow up learning it. Gas tight doors have not yet became so regularas we have so much old masonry around. Two other things on top of the experience also adds to security: the notion that excessive amount of liquor and chimney damper is not to be used in the same evening  and carbon monoxide alarming device (also quite regular here). Just want to say this with no any offence but I've had this discussion so many times and carbon monoxide alarming device (also quite regular here). Just want to say this with no any offence but I've had this discussion so many times  It was -7'C here already two days ago so all available heat is welcome. It was -7'C here already two days ago so all available heat is welcome.

OvenOperation and the heat retention are not satisfactory for my needs yet. I would need minimum of 250'C temp for my bread. Oven cools down now quickly to under 200'C after fire is gone. My assumption is that hot gasses pass the oven too quickly for it to retain the heat. Heating and stratification of the gases in the system in general seem to work properly now so it is good starting point to start tinkering with the oven as the primary function is ensured. For all that I would really appreciate community feedback and ideas!My thanksI want to once again thank especially you Peter, for your rock solid, patient, persistent and analytical pioneering work and ever helpful straight to the point approach. It feels so easy to just come to your site, take the numbers and build something so useful, ecological and inexpensive which is already thoroughly tested. You have done huge amount of beneficial work which you share freely and it is certainly one way to make the world better. Same goes with all of you co-innovators who have done and are doing the same and adding synergy into the whole process. I take my hat off for you (inside the house still). I'd love to return the contributions in any useful way. I can share my slide show diary about the building process showing more of the inner structure of the heater; just send me message if interested. The sketch up plan is already in sharing; what would be the best way to share by the way? Also Peter, if you would need a Finnish translation for your site for added exoticism let me know  ; we speak some kind of English here quite much but I already know many who would be interested about your concept being also masonry capable, but however would be stopped by the language... ; we speak some kind of English here quite much but I already know many who would be interested about your concept being also masonry capable, but however would be stopped by the language...

|

|

|

|

Post by travis on Nov 5, 2017 17:09:01 GMT -8

This is what is great to hear! A stove that's working well and keeping the house warm for extended times. Congratulations to you and good work. I hope to do the same in the coming years.

|

|

|

|

Post by Jura on Nov 5, 2017 23:39:25 GMT -8

[/i] Oven[/i]Operation and the heat retention are not satisfactory for my needs yet. I would need minimum of 250'C temp for my bread. Oven cools down now quickly to under 200'C after fire is gone. My assumption is that hot gasses pass the oven too quickly for it to retain the heat. Heating and stratification of the gases in the system in general seem to work properly now so it is good starting point to start tinkering with the oven as the primary function is ensured. For all that I would really appreciate community feedback and ideas![/quote] I'm joining you with this request. I'm also having problem even to more extent as I can not get my white oven hot more than 100 oC in a 18cm brick sidewinder. Although it is placed relatively high and close to the riser. donkey32.proboards.com/post/25638/threadBTW. i can not get the proper quotation here regardless the way I change th BBCode it gets back to wrong quoting manner |

|

|

|

Post by esbjornaneer on Nov 7, 2017 6:37:02 GMT -8

OvenFor all that I would really appreciate community feedback and ideas! Hi, A little off topic but here we go. Here in Southern Spain we have a solar oven that seldom go above 180C, most days reaching about 175C. We also make our own sourdough bread, 100% rye. And bake it in that solar oven most of the year. It takes a long time to cook compared with doing it in a 250C oven but it gets done in 1.5-3hours, depending on how wet the dough is when going into the bread tins. So a question is how long your temp will stay up, about 150C? Below 120C it is a bit low but there are recipes online for 'slow baking' the same as 'slow cooking' like is done with meat. Great to read your thread stove looking good and seems to work a treat! Looking forward to updates, Esbjorn |

|

|

|

Post by rakettimuurari on Nov 7, 2017 11:59:44 GMT -8

OvenFor all that I would really appreciate community feedback and ideas! Hi, A little off topic but here we go. Here in Southern Spain we have a solar oven that seldom go above 180C, most days reaching about 175C. We also make our own sourdough bread, 100% rye. And bake it in that solar oven most of the year. It takes a long time to cook compared with doing it in a 250C oven but it gets done in 1.5-3hours, depending on how wet the dough is when going into the bread tins. So a question is how long your temp will stay up, about 150C? Below 120C it is a bit low but there are recipes online for 'slow baking' the same as 'slow cooking' like is done with meat. Great to read your thread stove looking good and seems to work a treat! Looking forward to updates, Esbjorn Thanks Esbjorn, for interesting info and compliments! Slow baking... ; I must delve deeper into that! Sourdough rye here too  I am always just running after dark brown crust so that's why I' ve been using hi starting temps in electric oven - heat to 280'C; bread in and lower to 200'C -> 1 hour ... but this slow baking is something new and practical to test indeed! Temps have been poor to stay up; they will decrease under 120'C in 30 mins. While writing this I have my first oven modification in testing. I added one spacer piece into the oven ceiling. Basically i just added one more ceiling vault piece in the back edge of the roof exhaust in the oven. The piece is different to rest of the vault by being only 3cm thick and hanging 4 cm lower compared to the other vault pieces in the ceiling, thus forming a threshold for the gases to come around before exiting the oven. This way I am aiming to create a heat pocket in to the rear of the oven. I am also burning the record amount of wood for this stove so far - some 10kg. First 7 kg I did with the bypass open and the rest with the bypass closed, this all in order to avoid having sauna in living room. Shortly the embers are done and I will start to measure the oven temps. **Somewhat good news for the bakers; with my threshold piece in place and burning 1,5 batches (about 10kg) of wood I managed to achieve a temp of 210'C! Now the clock is ticking; lets see how soon it cools down... ***OK. After 1 hour there is still some 170'C in the oven! Esbjorn; I guess that will be very doable with the bread. My guess is that burning two full batches (15kg) would bring the thing to at least 250'C. ****Oven temp 2 hrs after the fire was bit less than 150'C. Ten hours later 70'C. I believe I will get still light improvement when I install the sliding closing damper in to the chimney stack. Later on I will burn two batches in the oven itself to see how it works, as I designed that option there too. It wont be so clean but it will surely heat the oven. Primary air comes through the riser and behind the threshold, secondary air from the door vents, in front of the threshold. I am planning to achieve secondary burn on the door side of the threshold just below the exit slot. Primary burn and wood is behind the threshold, in the oven rear. We'll see how it behaves. Cheers, -Antti- |

|

|

|

Post by esbjornaneer on Nov 8, 2017 0:01:39 GMT -8

Antti,

That sounds like great news! And you can definitely bake after a 10kg burn. The other tip I have picked up in the last year is that if you spray a fine mist of water over the bread before it goes into the oven it browns better/more.

Looking forward to pictures of your loaves when they come out, Esbjorn

|

|

|

|

Post by rakettimuurari on Nov 9, 2017 0:50:13 GMT -8

Damper installed

I punctured the chimney and installed the damper some 180cm above the heater's main chimney connection. I got bit worried as the chimney proved to be some 2cm narrower up there than it is in the bottom; little less than my CSA... I also installed the smoke gas thermometer at same height. Chimney temp proved to be some 65'C which almost made me bit scared, but... the draft is adequate and I have bypass in place. With the bypass open the temp was doubled to 120-130'C. It seems I am not heating the sky too much though... I just have a feeling that I ended up playing on the operational limits considering the relatively large ISA (have not made the exact calculation but I assume it to be somewhere at 7m2) and tighter than planned chimney but so far it has still been operating greatly. Moreover, as winter develops so will my draft, as usual. Observations in relation to below fed primary air

Lighting the batch from top is clearly not an option. Lots of smoke and painfully slow burn comes as a result. On the other hand lighting it from the bottom on the port side works like charm. I got the original very well working method from this video by Klemen. Lit like that the batch is in full burn in 2-3 minutes and very little smoke is visible even before that. Under air is efficient but seems to make the burn more vulnerable in relation of the fuel positioning. Most vigorous burn being in bottom it creates large cavities which then collapse later during the burn and in worst case may block the port (which usually in my case just seem to increase the strength of the burn...). So far this hasn't really been any problem yet. Care must be also taken in the beginning not to block the cast iron hearth covering the bottom inlet of the firebox when laying the fuel. I have been thinking the option to enlarge the air vent of the door to match per Peter's guidelines as I feel that it would provide more flexible and stable operation and enable the top down burn better. Now the CSA of the door vent is some 7,5% of the system CSA and is feeding mostly the floor channel and secondary burn. But if I am to keep the cast iron hearth for the embers to filter into the ash box below, then some cooling airflow also from below is required to keep the metal from getting ruined... On the other hand if I would manage to find feasible way to initiate fluent top down burn with the current set up, that would improve things too as fuel would stay more stabilized. I am still going to experiment still some more by giving air only via door crack and for a longer time in the beginning. About all this, your thoughts and feedback are appreciated! "The other tip I have picked up in the last year is that if you spray a fine mist of water over the bread before it goes into the oven it browns better/more.

Looking forward to pictures of your loaves when they come out, Esbjorn"Esbjorn: Thanks for idea; that would be even more crucial on this lower temp. I used to splash half desiliter of water to normal oven before closing the lid and that also worked but spraying would definitely be the correct option now. Regards, -Antti- Written in a cozy batchrockety room temperature of +24'C

|

|

|

|

Post by Orange on Nov 9, 2017 3:48:09 GMT -8

can you compare effects of damper vs closing the air inlet?

for the oven, you might need some metal or chamotte plate directly above the riser as the baking surface, should get higher temps.

|

|

|

|

Post by rakettimuurari on Nov 11, 2017 3:51:01 GMT -8

can you compare effects of damper vs closing the air inlet? for the oven, you might need some metal or chamotte plate directly above the riser as the baking surface, should get higher temps. Aye Orange; I will make comparison with the temps one day as I have finished all tweaking. The difference with damper is smaller than it would be with traditional contraflow heater; still at the moment I think damper adds 3-4 hrs to heat retention time. Damper is easier option as all the hatches except the fire box door are not gas tight. As for oven; I burnt two batches (in total some 6kg) directly in the oven itself first time yesterday. Definitely cleaned the black from oven walls but to my surprise the peak oven temp was some 10'C lower (195'C) than burning 10kg down there in actual firebox in the rocket. Also the heat load for the top part of the heater was much higher even with bypass open. So I decided to keep burning in actual firebox even for baking for the sake of heater's health and cleaner burning. Your suggestion for baking surface: will try something like that. The problem is the low height of the oven (23cm). At the moment I have added two firebrick splits standing on their sides around the riser inlet to the oven, effectively adding 12cm to riser height and same time forcing the gases from the riser shoot first against the oven ceiling. This seem to improve both the burn power and the oven temps. The splits can be then collapsed to the oven floor in the end of the burn in a case of baking as they are only 2,5cm high. |

|

|

|

Post by Orange on Nov 12, 2017 2:36:46 GMT -8

you can use chamotte splits or metal plate that goes around 5-6cm over riser, than you have space and the bottom temps should be high.

|

|

docbb

Junior Member

Back from ZA

Back from ZA

Posts: 92

|

Post by docbb on Nov 18, 2017 8:44:34 GMT -8

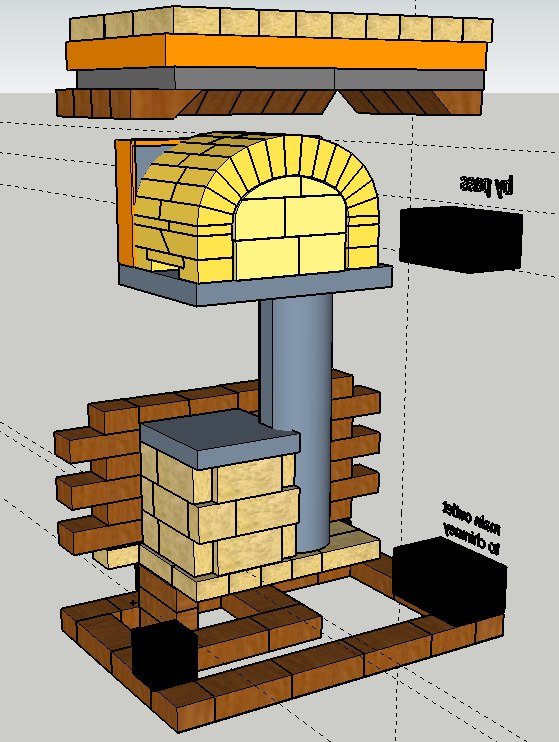

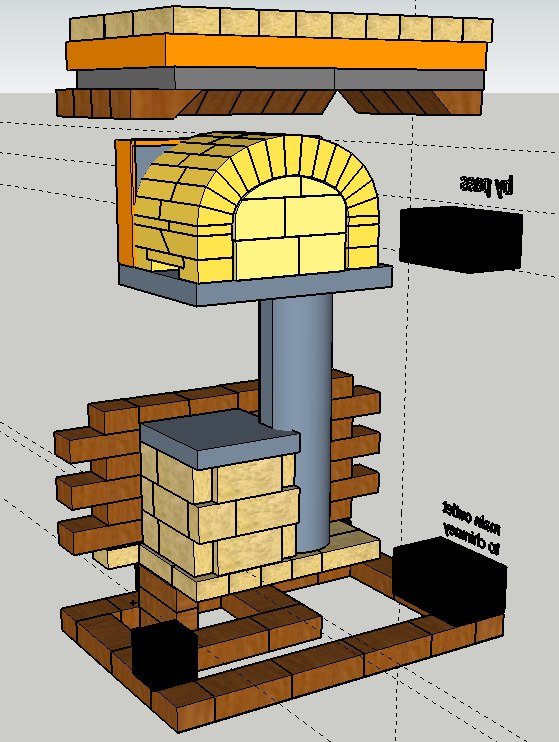

First full batch and floor channel in placeOvenOperation and the heat retention are not satisfactory for my needs yet. I would need minimum of 250'C temp for my bread. Oven cools down now quickly to under 200'C after fire is gone. My assumption is that hot gasses pass the oven too quickly for it to retain the heat. Heating and stratification of the gases in the system in general seem to work properly now so it is good starting point to start tinkering with the oven as the primary function is ensured. For all that I would really appreciate community feedback and ideas! Hello this could be what i would do to ensure a really hot oven for pizzas  The oven back wall is not thigh and maybe the fume lateral exits are a little too small, but it is the idea to have an hot oven sole |

|

|

|

Post by rakettimuurari on Nov 20, 2017 5:00:20 GMT -8

First full batch and floor channel in placeOvenOperation and the heat retention are not satisfactory for my needs yet. I would need minimum of 250'C temp for my bread. Oven cools down now quickly to under 200'C after fire is gone. My assumption is that hot gasses pass the oven too quickly for it to retain the heat. Heating and stratification of the gases in the system in general seem to work properly now so it is good starting point to start tinkering with the oven as the primary function is ensured. For all that I would really appreciate community feedback and ideas! Hello this could be what i would do to ensure a really hot oven for pizzas  The oven back wall is not thigh and maybe the fume lateral exits are a little too small, but it is the idea to have an hot oven sole Hi, Indeed; that is what i would try, if doing it all again; double sideways exit on oven floor; to start with total size of 2 x CSA or something? I did the roof vaults from castable for easiness. One more thing I realized; my oven floor is layered with 2,5 cm firebrick splits sitting free; no mortar. For my next bread I will remove those so only 6cm of refractory will be as oven sole. I'll see... I am relatively happy with the oven now as it was experimental to begin with. I can get it to 200'C with 1 and half full batches (some 10-12kg) of cord-wood burned in firebox. That's enough for my bread for sure and also for everything else I cook, like stews, casseroles etc. One full batch gives some 150'C from which 75'C is still left after 12hrs. I have plans for long made elk ice roast  For future builders my recommendations would be to omit ash box for additional height and more sealed firebox + not to mess with under air -> thus get more space above the oven which also enables insulation possibility for at least the roof vaults of oven. Personally I used every vertical cm I had, except one ! I have 26cm between heater top and ceiling compared to 25cm dicdated by the regulations. Combined with your oven exhaust suggestion that would make an interesting project! Not to mention the possibility to incorporate the horizontal burn tunnel/ riser construction below the oven floor instead of vertical riser, before bringing exhaust into the oven itself... |

|