|

|

Post by patamos on Feb 17, 2015 22:06:10 GMT -8

Thanks Peter

Eric, was your request for a sketch to do with secondary air intake or the simple rigging of a bypass flue set up?

If the former, it looks like Peter has answered it. If the latter i will get a sketch up soon.

|

|

|

|

Post by ericvw on Feb 18, 2015 18:58:51 GMT -8

Well, patamos, both! I see that peterberg addressed the initial question, and I'm interested to see your take on his response- did he nip it in the bud for you? And as for this bypass situ, whatcha got? Back to the secondary in the wall, so to speak.... I wonder if a tunnel(cast in place?) in the side wall of the refractory casting would withstand the rigors? Probly be too thin, and subject to breakdown/ cycling... Still, just throwin it out there. Eric VW |

|

|

|

Post by pianomark on Feb 18, 2015 20:19:52 GMT -8

.... I wonder if a tunnel(cast in place?) in the side wall of the refractory casting would withstand the rigors? Probly be too thin, and subject to breakdown/ cycling... Eric, It sounds like your idea is heading in a similar direction to my current thoughts. I haven't given up on the idea of injecting secondary air through the casting walls. This is mainly to keep metal out of the firebox. I understand that the air will need to be intensely preheated, as Peter pointed out in my earlier thread. My current idea/plan is casting two lengthwise channels underneath the firebox, replacing the two "feet" and triangular space beneath the sloped walls. These channels go all the way to the back, then slightly upward through the two triangular corners formed outside the octagonal riser, then through spaces where the riser sidewalls are thinned slightly to create passages back toward the front and injected through the sidewalls to the appropriate place in the throat. The riser section of the casting could then be enclosed in a metal box of sorts to create the passages when external insulation is added. None of these feed channels actually go through the casting (excepting the last two inches through holes in the walls. Rather, the preheating channels would be formed into the outside of the casting, and enclosed by the floor/box/insulation. Or maybe I can figure a way to do it without ANY metal.... Yes, I know this will steal heat from the riser. I was hoping to avoid that. But the stolen heat will be immediately dumped back into the riser. Still a net loss, I know. Not sure how else to get the secondary air hot enough. How hot does the exhaust get in the manifold area, immediately behind/below the riser? Seems it would benefit the draft to take heat from there, but not sure if it gets hot enough. Mark |

|

|

|

Post by patamos on Feb 18, 2015 22:15:39 GMT -8

Well, it is all still theoretical for me. But it sounds like two key factors are 1 - having the air streaming uphill if possible, and 2 - releasing it into a space 1 or 2 (?) inches upstream of the throat where there is negative pressure. With this side riser variation there are many questions still being sorted out regarding how to optimize gas flow, turbulence and secondary combustion. Eg. How far forward from the corner to set the throat…. What kind of asymmetrical riser might work best… all of which is related to the question of where is the ideal place and angle to be releasing that secondary air. Could be that a combination of factors would lend themselves to having air injected from just the fore side. In which case maybe a cast iron plate loosely set into the side wall could be worth a try. It looks like Matt is putting himself to work researching these varieties… What with his capacity for nutting things out, the answers are bound to be on their way  will get that sketch (or pic) re bypass routing happening soon. |

|

|

|

Post by hendrik on Feb 22, 2015 11:21:47 GMT -8

Peter, i think Adiel was just saying his was with a front door, and a side window. And wondered why nobody turned that side window into a side door. I think it's perfectly possible, and think i've seen one. In prototype form. But can't seem to find it. Well, I just happen to finish a rocket stove with a front door. It's working perfectly.  In a tiny nutshell: I built from scratch a cooking stove with a RBB inside, with a front loading door, and stones from a second-hand soapstone stove. The rocket is behaving well, but I did notice the P-channel reduces the exit temperatures. Now I know why: adding the big door adds also extra oxygen in the burning chamber. So my burning chamber turns out to be bigger than the standard R177-design. Our rocket burns happily with a front door, and without the P-channel now. Exit-temperatures up to 730°C. If you like to see detailed build pictures, it's all here: www.ecologieforum.eu/viewtopic.php?f=3&t=4610If you would want more infomation about this build, don't hesitate to ask. cheers, Hendrik |

|

|

|

Post by satamax on Feb 22, 2015 11:36:12 GMT -8

Dat's a real nicee one mate! Love it!

I'll abide by your words!

I'll relay it on permies if you don't mind. Did you test the emissions?

|

|

|

|

Post by shilo on Feb 22, 2015 12:15:33 GMT -8

the hitrizer is 8B?

|

|

|

|

Post by hendrik on Feb 23, 2015 8:06:00 GMT -8

The heat riser is 6 inch section (diameter), 34 inch high.

That gave us a net energy equivalent of 17 - 18 kWh.

More than enough for a cooking stove + kitchen heater + sanitary warm water heater.

The heat riser is self made from superwool+rigidizer.

No problem to show it on permies. Inspiration is good.

Unfortunately I can't afford a Testo analyzer, so I can only say that

- it doesn't smoke or smell

- it starts like a batch rocket

- it burns like a batch rocket

- and it roars like a batch rocket

So I guess it's a batch rocket then... :-)

cheers!

Hendrik

|

|

|

|

Post by shilo on Feb 23, 2015 8:53:13 GMT -8

|

|

stoker

Junior Member

Posts: 61

|

Post by stoker on Mar 10, 2015 14:13:42 GMT -8

Hendrik, that's beautiful.

Where are you measuring 730°C?

And how did you conclude 17-18kWh?

What is the R177-design? (This forum's search-function finds only your mention of R177.)

|

|

|

|

Post by satamax on Mar 10, 2015 15:51:47 GMT -8

|

|

|

|

Post by hendrik on Mar 13, 2015 9:11:52 GMT -8

Where are you measuring 730°C? And how did you conclude 17-18kWh? What is the R177-design? (This forum's search-function finds only your mention of R177.) Hi stoker, The max. temperature measured at the exit of our stove was 730°C. I need such a high temperature, because I use the exhaust gases as input for a sanitary warm water heat exchanger at the other side of the wall. So internally my rocket is exceptionally well isolated. An "R177" (Rocket with heat riser surface of 177cm² (=diameter of 15cm)) gives me the following calculation: -- it can easily burn 5kg of dry wood in 1 hour -- 5 x 4kWh energy/kg= 20kWh -- 20kWh burnt with an average efficiency of 90% = 18kWh. Sorry for the late reply, I'm working on the hydraulic connection behind the rocket. It seems to work out very fine. cheers, Hendrik |

|

|

|

Post by vuurenvlam on May 7, 2015 5:58:45 GMT -8

Hendrik, do you see the same problems as Adiel, opening the side door during a burn causes smoke to escape? I'm curious if the side-riser has any impact on a BBR with a side window, or if the two are unrelated.

|

|

|

|

Post by hendrik on Sept 1, 2015 1:35:18 GMT -8

Hi vuurenvlam,

Sorry for the late reply. I didn't get a comment-notice from the website.

About the side window:

Indeed. It's almost impossible to open the side door *during a burn* without smoke escaping.

Wood can only be added at the end of the burn.

I read about this in advance, and considered it not to be a big disadvantage, since it is a *batch* rocket.

We fill it with about 5,5kg per batch.

Only 50 minutes later we do a refill.

If we really need to add wood sticks intermediately, (e.g. if we're cooking a large steak) we add sticks through the hole of the primary air inlet...

Which is opposite of the heat riser. (round hole on the left of my picture)

It's a small cost for the joy of seeing the flames while we're at the breakfast table...

Cheers,

Hendrik

P.S. Note that I do not have a side riser. I have a "normal" batch box, with a side window.

|

|

|

|

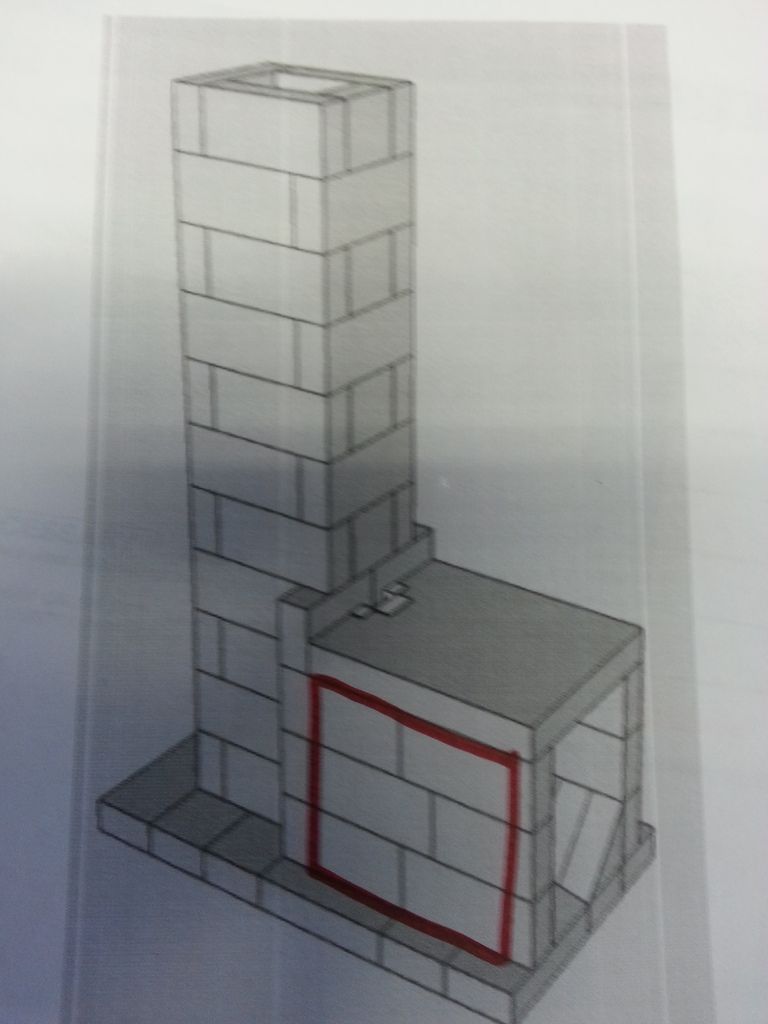

Post by chrisz on Oct 14, 2015 13:01:19 GMT -8

I'm looking for a little more clarification please. can i modify a batch box rocket mass heater to load out the side instead of the front? By can I, I also mean, without having to re design anything complicated on the rest of the stove. For clarity, per my attached picture I'm looking to removing the bricks in the red square, that would be open for loading and cleaning, yet sealed airtight with a door with glass for viewing. I would also block off the opening on the right, the "regular" opening as I only need one door.  |

|