|

|

Post by peterberg on Jul 16, 2008 12:04:14 GMT -8

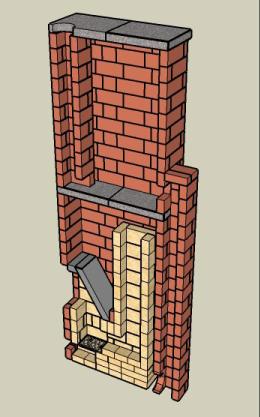

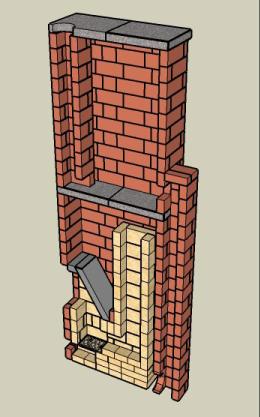

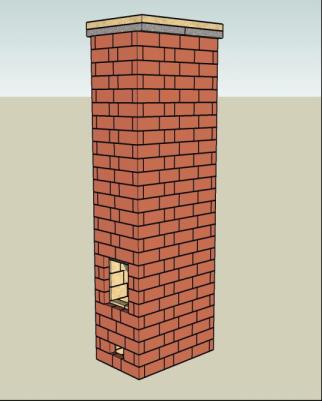

Donkey suggested in this thread that I registered and started a thread on the rocket / bell combination. Well, here I am. The past month I did build one such a stove, purely experimental. The rocket itself is built from firebrick, no insulation at the moment. The bell is an empty box completely covering the rocket, with a small door in one of the sides. It's built as a 7" system, with the feed tube about three times as wide as the burn tunnel. Height of the heatriser is 3' 7", the whole contraption 4' 1" when measured from floor level. The chimney pipe is a 6" one, starting at the very bottom of the bell, behind the heatriser. The (single) bell is internally 1' 5" wide, 2' 4" deep and 8' 6" high. I know, it's ridiculously high, because I wanted to find out when there would be too much room above the rocket and stopped working altogether. The answer is plain: there is probably no limit. The bell is made of ordinary bricks, used on its side and loosely bond together with a pottery clay and sand mix. The top were two concrete slabs normally used for pavement, with no rebar in it. Last Sunday I started the thing up. Not successful at first, with lots of smoke in the workshop. After that fire died down I tried to prime the heat riser with an electrical paint stripper for an hour. After that the rocket started without problems. Maybe the thing wasn't dried enough out yet. Anyway, having the thing running I inserted the Testo gasanalyzer in the chimney pipe. That analyzer measures the CO, O2, and end temp among other things. Via an embedded formula it calculates the efficiency. The CO level made several large and unexpected jumps, the end temp was quite low, between 145 and 250 F during the course of the 4-hour run. The calculated efficiency was insanely high and varied between 80% and 95.2%. Temp of the thin brick skin (on outside) varied from top to bottom a mere 68 F, with the highest readings right under the top, which were 320 F. Personally I regard the results as very good. Five years ago I have designed a small Finnish contraflow which is in production again since last year. Readings from that one have never been higher than 84% efficiency, which is quite good. Next move: do more testing and draw some line graphics, change the single bell into a double. |

|

|

|

Post by canyon on Jul 17, 2008 0:29:06 GMT -8

Peter, That sounds very exciting. What inspired you to do this? What is the goal you are heading towards? I'm so glad you are sharing your experience. I have a feeling this concept could work well for an outdoor cooking,baking, and drying oven/kiln I have in mind. Please keep us posted!  |

|

|

|

Post by peterberg on Jul 17, 2008 11:41:19 GMT -8

Peter, That sounds very exciting. What inspired you to do this? What is the goal you are heading towards? Canyon, Inspiration came from Sjang van Daal, a Dutch expatriate in Norway. He is developing a core-kit to build a rocketstove mass heater. The bell side came from Igor Kusznetsov in Russia and Alex Chernov in Canada. Both are mass heater builders. The small footprint of my prototype came from the design of the contraflow heater, mentioned before. The goal is to develop a commercial stove which will fit inside the shell of the existing contraflow. Two men, younger than me, earn a living with building this precast stoves. It would be nice (for them) to have a somewhat larger portfolio, so they have more options to offer. see www.bergkachel.nl It's in Dutch, but the pictures speak for themselves And me, oh well, I like to tinker with things not tried before. It helps to be a regulated pyromaniac. |

|

|

|

Post by Donkey on Jul 18, 2008 12:48:14 GMT -8

Your smokiness problem may be made much worse by the size of the feed tube.

I've tried to increase the size of the feed many times and have found that it really needs to be the same (or very nearly so) as the rest of the system for proper draw.

I do like a slightly longer feed tube, as it allows me to get my forearm in there for cleaning. It necessitates a brick or some such thing to narrow the feed, otherwise it just won't pull all the smoke down the feed and into the fire.

This is an unfortunate situation, it would be nice to feed larger pieces and/or more in at a time.

I have been playing with ideas to fix this problem, though haven't come up with anything definite that I can point to and say "this is how it's done".

Your findings thus far are encouraging and your project overall is VERY interesting.. Please do keep us all up to date as it progresses.

I would like to see pictures of the gizmo, inside and out. Plan drawings or even rough sketches would be nice too.

|

|

|

|

Post by peterberg on Jul 19, 2008 8:35:40 GMT -8

Hi Donkey,

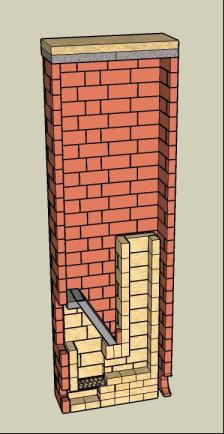

Pictures and drawings? Can be done. I made a SketchUp model today, and made some small JPEGs out of it. I'll send it to you, I am somehow too clumsy with websites. You can publish them here, if you like.

|

|

|

|

Post by Donkey on Jul 19, 2008 8:44:58 GMT -8

Hrmph... What's needed is some free webspace someplace for just this purpose... Mine, while relatively cheap, is filling up... Ah well, go ahead and send em', I'll post em'. It's for a good cause and I'm curious.  |

|

|

|

Post by peterberg on Jul 20, 2008 11:00:56 GMT -8

|

|

|

|

Post by Donkey on Jul 20, 2008 14:57:36 GMT -8

VERY COOL!!

I get it.

Clean design, simply made, small footprint, way to go!

|

|

|

|

Post by canyon on Jul 20, 2008 23:57:38 GMT -8

Awesome! Thank you so much for posting the pics and drawings as my mental picture from your description was a bit off. Can you remove or open the angled cover over the feed tube to clean out ash? Where would you add another bell? What do you estimate the total weight to be?

Canyon

|

|

|

|

Post by peterberg on Jul 21, 2008 12:50:03 GMT -8

The angled cover is not removable from outside. Any ash in the bell will accumulate on the floor behind the heatriser. And can be removed through the hole of the stovepipe.

The bottom of the ashpit is a grid. Underneath is a space which can be emptied via the ash door.

This experiment is done with a single large bell. The next one would be a double bell, one on top of the other. Such a construction is a bit more complicated. But wait and see, in a couple of weeks this one will be replaced by a double version. I'll keep you posted.

The weight? Hmpf... about 800 kilograms. That would equal roughly 1600 pounds. The walls of the bell are too thin like this, for a permanent stove I wouldn't use the bricks on its side. Unless you would make it with double walls. Properly built, I estimate the weight would be... 1200 kilograms.

|

|

|

|

Post by Donkey on Jul 21, 2008 16:34:51 GMT -8

What kind of exit/stack temperatures are you seeing with this?

How much heat is staying in the mass? I imagine the bell distributes heat well throughout..

How long is this stove staying hot/warm after a firing?

|

|

|

|

Post by peterberg on Jul 22, 2008 11:37:47 GMT -8

What kind of exit/stack temperatures are you seeing with this? How much heat is staying in the mass? I imagine the bell distributes heat well throughout.. How long is this stove staying hot/warm after a firing? Highest readings for exit temp is 320 F, but it comes on very slow. In the course of one hour it went gradually up from 85 F to 250 F during the latest test (this evening). I'm afraid I don't understand the second question. Do you mean efficiency? Distribution of heat is excellent, indeed. No hot spots and not much difference between top and bottom. I think that's the reason why cracks are still absent. Fired in the evening, the next morning it is still warm to the touch, with a real warm area around the rocket. When equipped with 4" outer skin instead of the 2" at present, I'm still not convinced it could be a genuine 24-hour stove. |

|

|

|

Post by Donkey on Jul 22, 2008 13:25:44 GMT -8

I fully expect the bell system to be VERY good at distributing heat evenly. This is a place where most rocket stove/bench systems are not so good. The bench will be warmer on the side nearest the stove core. Of course, cracking is quite likely next to the fire as well and tends to be a regular feature. Though where the bench system is quite good is in it's ability to store heat for a very long time (I've personally experienced somewhere upwards of 3 days) in a very useful place (where you are likely to sit). Stack temperatures in the typical bench system are so low that the stovepipe can be hugged or even licked.. Ianto Evans likes to prove it to the astonishment of his visitors..  This seems good, in that more of the heat produced is then stored in mass, though too much mass can lead to other problems. I've experienced condensation problems when too much heat is soaked up by the mass of the bench. Mainly a tuning issue, though it does come up. I confess that I didn't understand what you meant when you first described the bell and am still somewhat mystified by the idea of a double bell.. This opens up some new avenues of thought for me.. I am very much looking forward to your further explorations in this and PLEASE continue to share your results... |

|

|

|

Post by peterberg on Jul 23, 2008 9:25:51 GMT -8

Hugging or licking the stovepipe is not the same as actually measuring the temperature in the core of the gas stream.

But, I've checked that too a couple of times. Hrmph... (calculating the notes from Celcius to Fahrenheit). With the heart of the stovepipe well over 200 F, the outside gives readings of less than 100 F.

Sound very good to me.

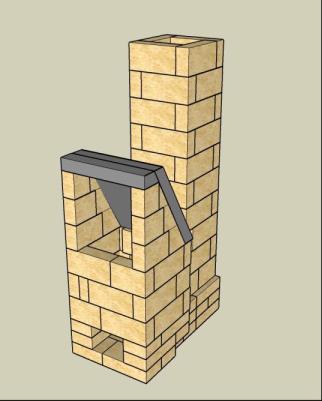

To clarify what a double bell with a rocket inside would be like, I'll make another drawing tonight.

|

|

|

|

Post by peterberg on Jul 23, 2008 13:09:44 GMT -8

Drawing is ready. Easy, just editing a copy of the single one. The difference is twice an updraft and downdraft instead of once. The exit to the chimney could be halfway at the front, at the top of the front or at the top deck, like this drawing shows. As a contrast, the single bell's chimney exit is always somewhere at floor level.  The double bell should be a bit better at efficiency, but has the tendency of more friction in the smoke path. The first updraft channel could also be inside the first bell, or as two smaller ones, left and right. The distributing of heat would be different: the hottest part shifts from top to halfway. The second bell could also be behind the first, with a different height and shape as well, even on a different floor level. Perhaps in the form of a bench? Not with stovepipe inside but large clay flue liners. Not for sale here, but normal in the U.S., I've come to understand. According to the bell principle even quite large ones should work. |

|

This seems good, in that more of the heat produced is then stored in mass, though too much mass can lead to other problems. I've experienced condensation problems when too much heat is soaked up by the mass of the bench. Mainly a tuning issue, though it does come up.

This seems good, in that more of the heat produced is then stored in mass, though too much mass can lead to other problems. I've experienced condensation problems when too much heat is soaked up by the mass of the bench. Mainly a tuning issue, though it does come up.